Catalyst for preparing 1,6-hexanediol through direct reduction of adipic acid

A catalyst, adipic acid technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, organic chemistry, etc., can solve the problem of low reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

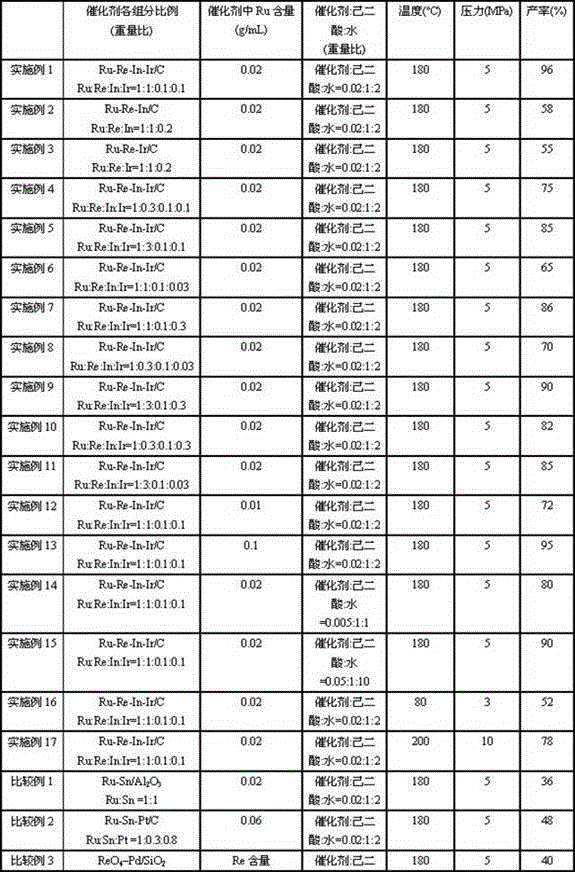

Examples

Embodiment 1

[0020] Catalyst preparation:

[0021] RuCl 3 , NH 4 ReO 4 , InCl 3 and H 2 IrCl 6 Dissolved in 50mL of water, the masses of Ru, Re, In, and Ir metals in the solution are 1g, 1g, 0.1g, and 0.1g, respectively. Add 50mL of 60-mesh coconut shell charcoal that has been treated at 70°C for 5h with a concentration of 35wt% nitric acid aqueous solution, washed to neutral and dried, impregnated for 12h, and dried at 120°C for 3h to obtain a catalyst precursor, and the catalyst The precursor was placed at 500°C for 3 hours with hydrogen diluted 5 times with nitrogen to obtain a catalyst. According to ICP-AES analysis, the Ru loading in the catalyst was 0.02g / mL, and the weight ratio of each component of the catalyst was Ru:Re: In:Ir=1:1:0.1:0.1.

[0022] Catalyst evaluation:

[0023] Add 100g of adipic acid solids, 200mL of water, and 2mL of the above-mentioned catalyst into the autoclave, start stirring, first pass through nitrogen for three times, then pass through hydroge...

Embodiment 2

[0025] Catalyst preparation:

[0026] RuCl 3 , NH 4 ReO 4 and InCl 3 Dissolved in 50mL of water, the masses of Ru, Re, and In metals in the solution are 1g, 1g, and 0.1g, respectively. Add 50mL of 60-mesh coconut shell charcoal that has been treated at 70°C for 5h with a concentration of 35wt% nitric acid aqueous solution, washed to neutral and dried, impregnated for 12h, and dried at 120°C for 3h to obtain a catalyst precursor, and the catalyst The precursor was placed at 500°C for 3 hours with hydrogen diluted 5 times with nitrogen to obtain a catalyst. According to ICP-AES analysis, the Ru loading in the catalyst was 0.02g / mL, and the weight ratio of each component of the catalyst was Ru:Re: In=1:1:0.1.

[0027] Catalyst evaluation:

[0028] Add 100g of adipic acid solids, 200mL of water, and 2mL of the above-mentioned catalyst into the autoclave, start stirring, first pass through nitrogen for three times, then pass through hydrogen for three times, and then pass...

Embodiment 3

[0030] Catalyst preparation:

[0031] RuCl 3 , NH 4 ReO 4 and H 2 IrCl 6Dissolved in 50mL of water, the masses of Ru, Re, and Ir metals in the solution are 1g, 1g, and 0.1g, respectively. Add 50mL of 60-mesh coconut shell charcoal that has been treated at 70°C for 5h with a concentration of 35wt% nitric acid aqueous solution, washed to neutral and dried, impregnated for 12h, and dried at 120°C for 3h to obtain a catalyst precursor, and the catalyst The precursor was placed at 500°C for 3 hours with hydrogen diluted 5 times with nitrogen to obtain a catalyst. According to ICP-AES analysis, the Ru loading in the catalyst was 0.02g / mL, and the weight ratio of each component of the catalyst was Ru:Re: Ir=1:1:0.1.

[0032] Catalyst evaluation:

[0033] Add 100g of adipic acid solids, 200mL of water, and 2mL of the above-mentioned catalyst into the autoclave, start stirring, first pass through nitrogen for three times, then pass through hydrogen for three times, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com