Sand box overturning device for iron mold casting production line

A technology of casting production line and turning device, which is applied to casting equipment, manufacturing tools, equipment for handling casting molds, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

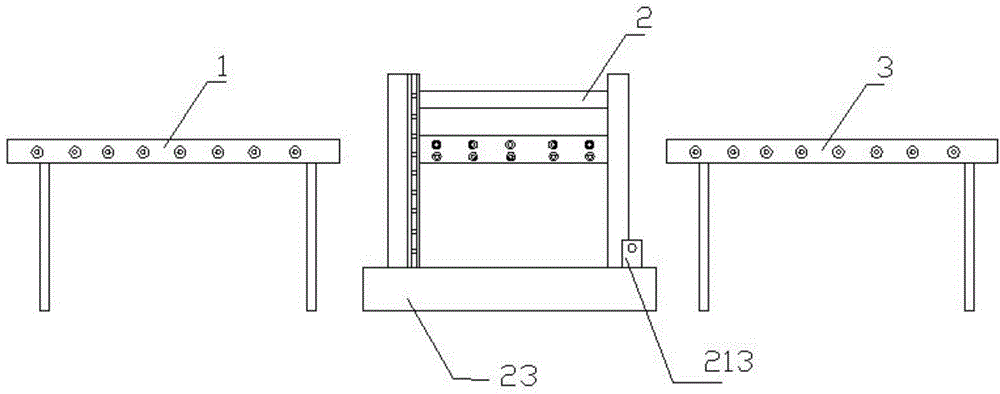

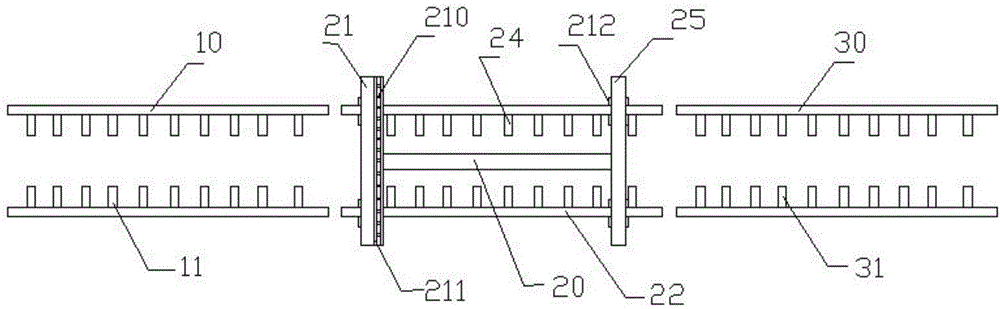

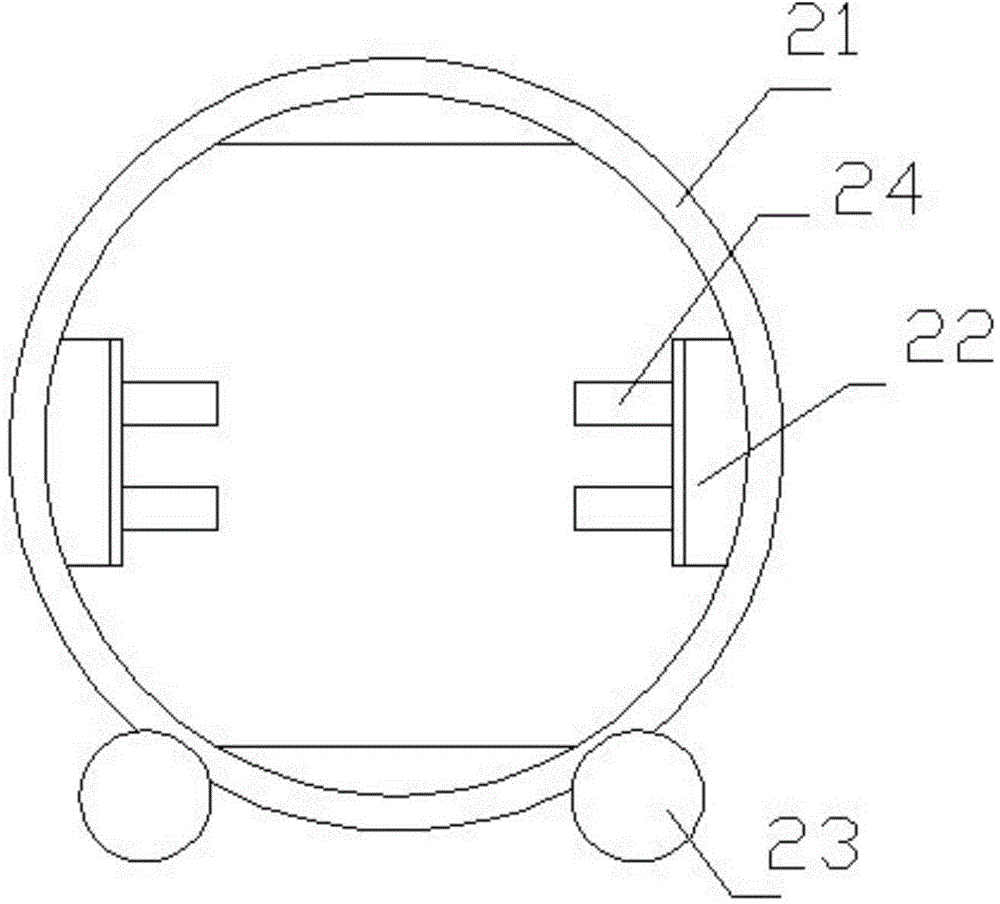

[0032] This embodiment includes a sand box sending mechanism 1, a sand box turning mechanism 2 and a sand box sending mechanism 3. According to the direction of the sand box running, the sand box sending mechanism 1 is located in front of the sand box turning mechanism 2, and the sand box sending mechanism 3 Located at the rear of the sand box turning mechanism 2, the sand box turning mechanism 2 includes a crossbeam 20, a rotating ring, a sand box support plate 22, a turning ring support frame 23 and a turning ring driving device that drives the turning ring to rotate, and the crossbeam 20 is connected to the rotating ring. On the ring, the sand box supporting plate 22 is connected on the rotating ring, and the rotating ring is installed on the rotating ring supporting frame 23, and the rotating ring can rotate on the rotating ring supporting frame 23, and the described sand box supporting plate 22 is provided with a roller table 24 , The roller table 24 is made of a plurality...

Embodiment 2

[0039] This embodiment includes a sand box sending mechanism 1, a sand box turning mechanism 2 and a sand box sending mechanism 3. According to the direction of the sand box running, the sand box sending mechanism 1 is located in front of the sand box turning mechanism 2, and the sand box sending mechanism 3 Located at the rear of the sand box turning mechanism 2, the sand box turning mechanism 2 includes a crossbeam 20, a rotating ring, a sand box support plate 22, a turning ring support frame 23 and a turning ring driving device that drives the turning ring to rotate, and the crossbeam 20 is connected to the rotating ring. On the ring, the sand box supporting plate 22 is connected on the rotating ring, and the rotating ring is installed on the rotating ring supporting frame 23, and the rotating ring can rotate on the rotating ring supporting frame 23, and the described sand box supporting plate 22 is provided with a roller table 24 , The roller table 24 is made of a plurality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com