Coarse-fine milling cutter capable of discharging scraps quickly

A rough, precise and fast technology, applied in the direction of milling cutters, milling cutting blades, and tools for milling machines, etc., can solve the problems of affecting the processing of workpieces, short service life, and easy wear of tools, so as to improve efficiency and service life , Reduce the effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

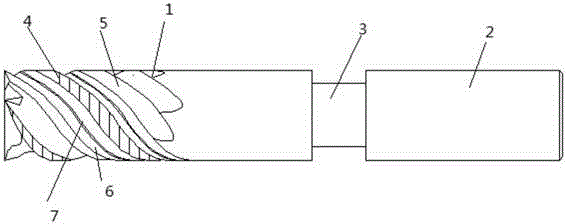

[0011] refer to figure 1 , a kind of rapid chip removal rough and fine milling cutter, comprising a handle 2 and a cutter head 1 connected to one end of the cutter handle 2, the cutter head 1 is provided with a helical cutting edge, and the cutting edge includes a rough cutting edge 4 and Finishing cutting edge 5, a chip flute 6 is formed between the cutting edges, and the bottom of the chip flute 6 is provided with a strip-shaped protrusion 7, and the strip-shaped protrusion 7 extends from the front section of the chip flute to the chip flute At the rear end of 6, an annular slot 3 is provided on the handle.

[0012] There are four cutting edges, and the cutting edges include two rough cutting edges 4 and two fine cutting edges 5 .

[0013] The two rough cutting edges and the two finishing cutting edges are arranged at intervals.

[0014] The outer surface of the cutter head 1 is coated with a chromium nitride coating, which effectively reduces the abrasion of the cutter he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com