Integrated framework and bogie

An integral and framed technology, which is applied in bogies, railway car body parts, railway transportation, etc., can solve the problems of poor fatigue performance of carbon fiber interface design, poor fatigue resistance performance, and great difficulty, so as to avoid Low fatigue strength, improved bogie performance, and reduced noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

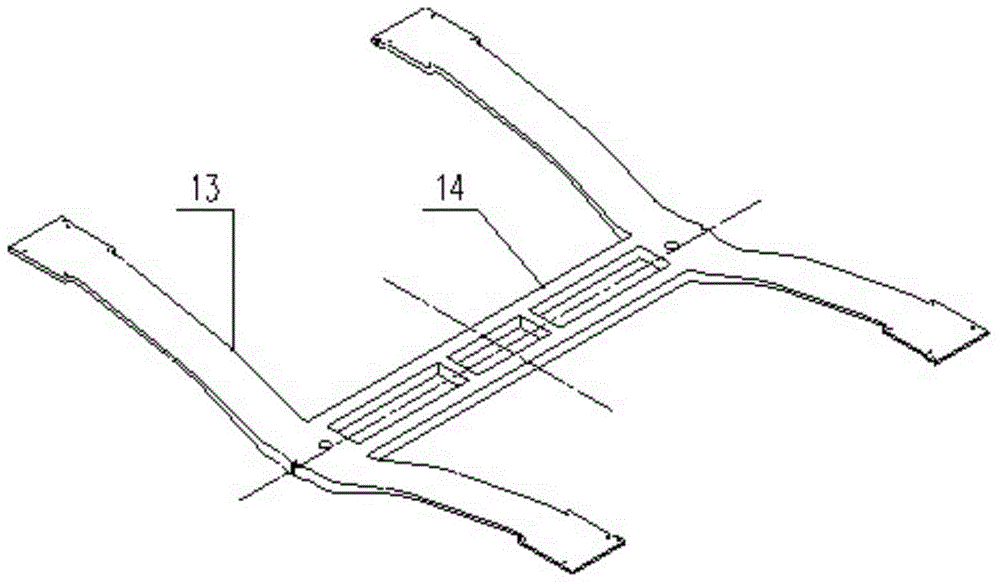

[0029] A monolithic framework such as figure 1 and 2 As shown, it is mainly composed of two side plates 13 and a beam 14, the side plate 13 and the beam 14 are an integrated structure, the side plate 13 and the beam 14 are made of resin-based carbon fiber composite materials or ceramic-based carbon fiber composite materials, Wherein the side plate of the frame is V-shaped, and the side plate 13 is provided with a series of spring mounting seats 15, a series of spring mounting seats 16, etc., which mainly carry the weight of vehicles and passengers. The first series of springs 6 are fixed by bolts and positioning holes; the second series of springs 3 Fixed in the middle of the side plate, the positioning hole 18 fixes the secondary spring 3 on the frame, and can be rotated slightly around the positioning hole 18 to increase the lateral deflection of the secondary spring to adapt to the small curve passing and high-speed operation of the bogie. The crossbeam 14 is provided with...

Embodiment 2

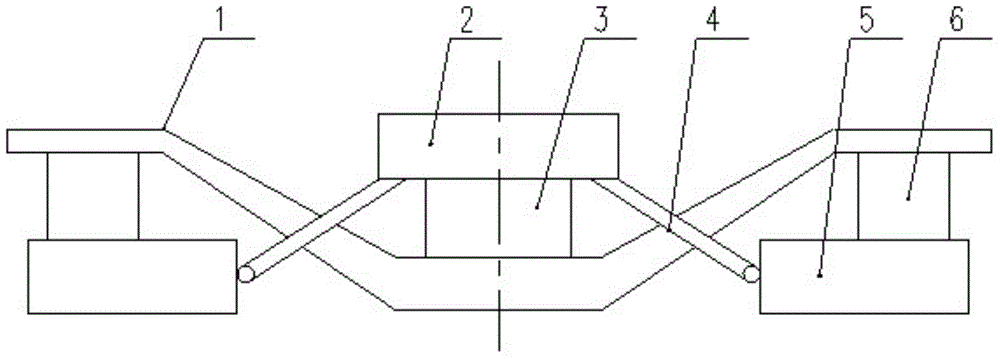

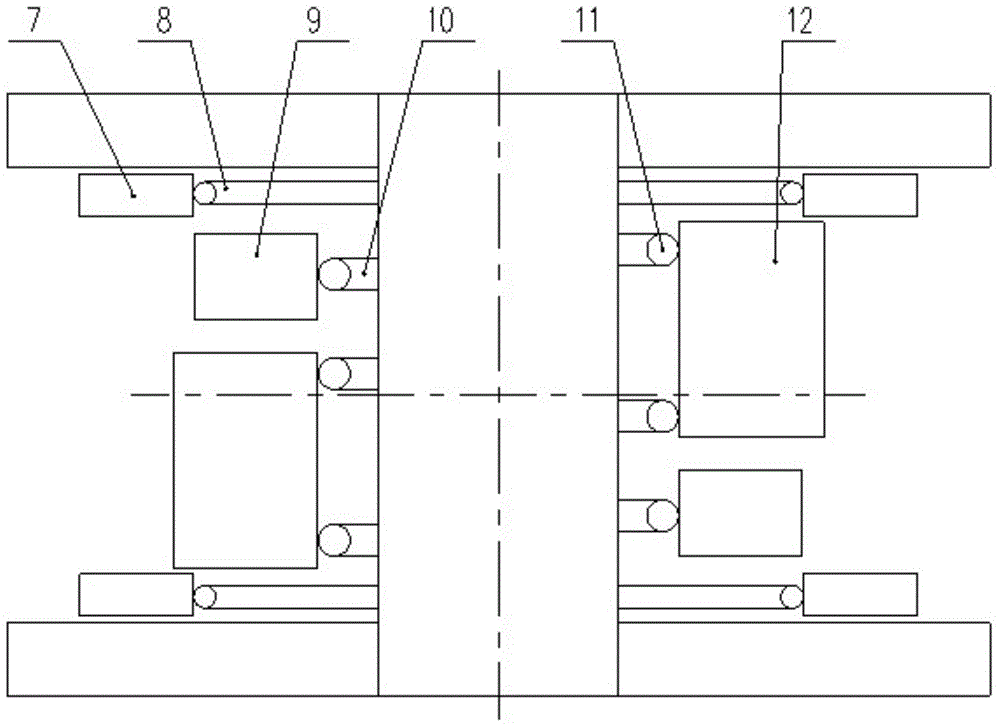

[0034] A bogie, comprising the frame 1 as described in Embodiment 1, a series of springs 6 are housed in the first series spring mount 15, and a second series spring 3 is housed in the second series spring mount 16; The axle box pull rod assembly 4 is connected with the axle box 5, the motor mount is connected with the motor 12 through the motor suspension assembly 11, and the gear box hanger is connected with the gear box 9 through the gear box suspension rod assembly 10; the motor 12 , the gear box 9 and the braking assembly 8 are all arranged on both sides of the beam 14 and between the two side plates 13 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com