Multi-effect double-medium filter

A filter and dual-media technology, applied in gravity filter, loose filter material filter, filter separation, etc., can solve the problem of poor effect of the filter material layer, poor fluidity in the area of serious glue connection and the near wall side, and filter material Uneven backwashing effect of surface pollutants and other problems, to achieve the effect of prolonging the treatment effect, reducing the broken rate, and facilitating maintenance or replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

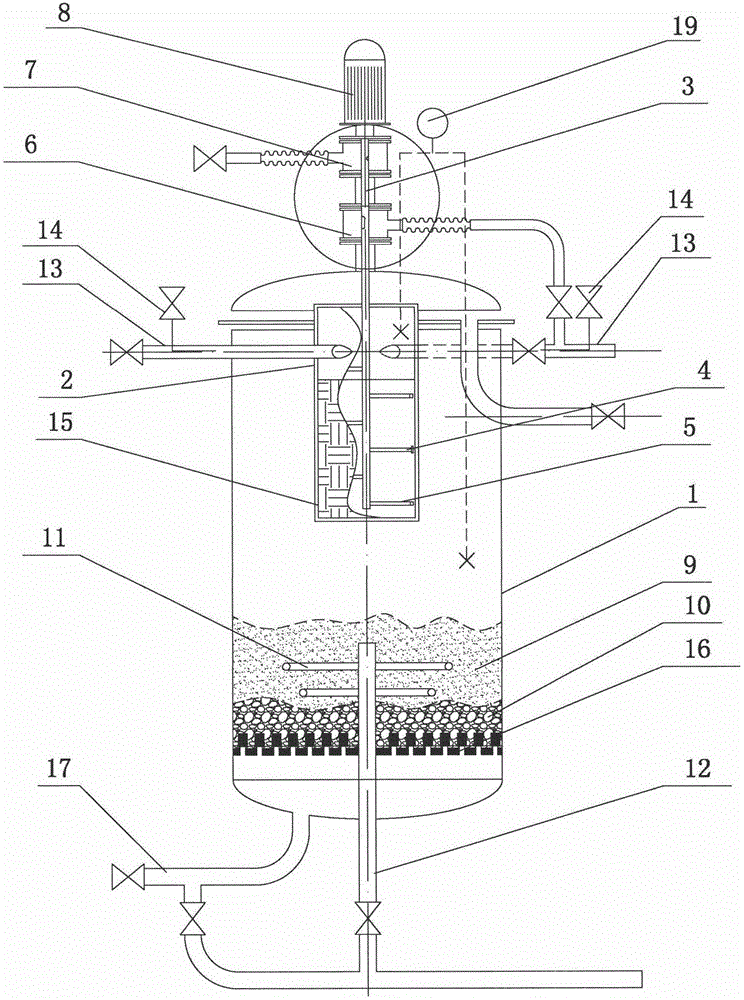

[0024] Please refer to the attached figure 1 To attach Figure 4 As shown, the present invention is a multi-effect dual-media filter, which consists of a filter housing 1, a primary filter inner cylinder 2, a hollow shaft 3, a backwash nozzle 4, a slag suction pipe 5, and a backwash buffer nipple 6 , slag removal buffer nipple 7, sewage suction motor 8, light filter material layer 9, heavy filter material layer 10, circulation backwash structure 11 and backwash main pipe 12 and other parts.

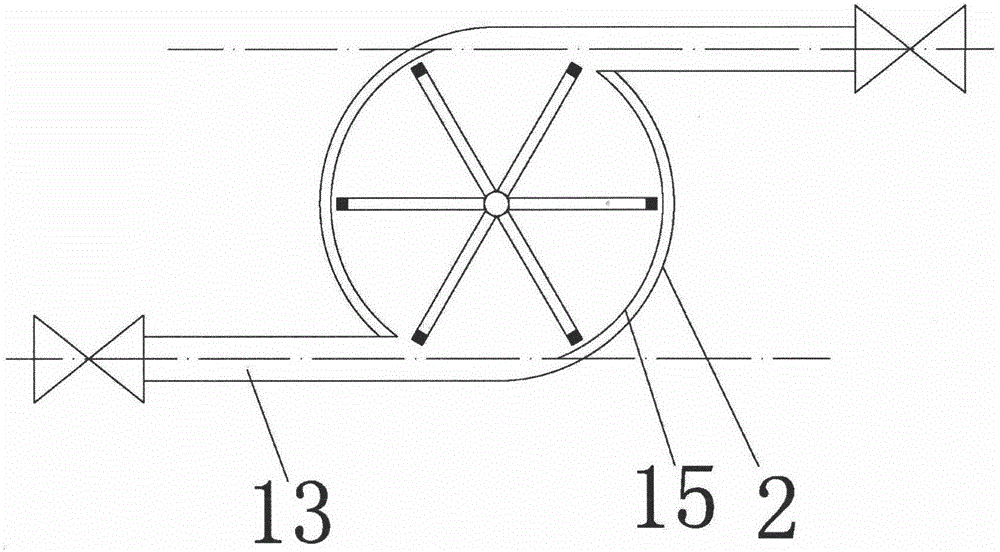

[0025] Wherein, the primary filter inner cylinder 2 is arranged in the filter housing 1, and water inlet pipelines 13 are arranged symmetrically on both sides thereof. A water inlet aeration structure 14 is arranged on the water inlet pipeline 13 . A filter screen 15 is arranged inside the primary filter inner cylinder 2 .

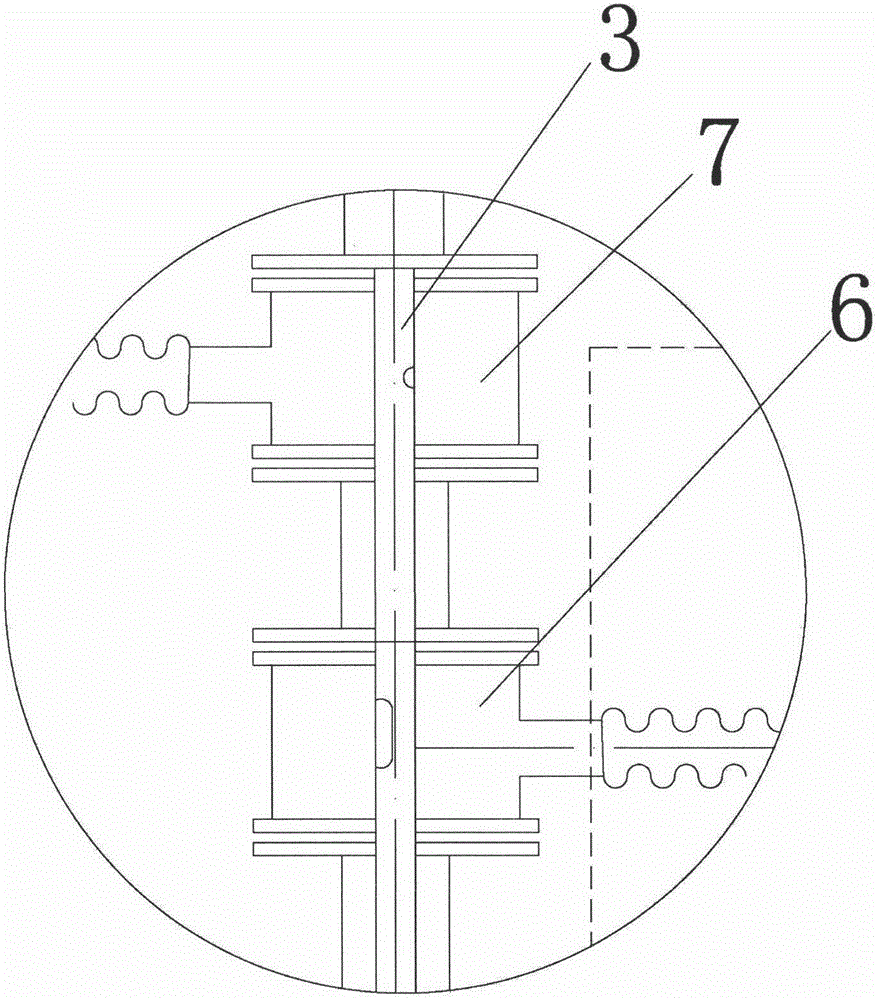

[0026] The hollow shaft 3 is divided into two independent cavities, one of which communicates with the backwash buffer nipple 6 and the backwash nozzle 4, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com