A kind of ecological concrete and preparation method thereof

A technology of ecological concrete and admixture, which is applied in the direction of ceramic products, other household utensils, applications, etc., can solve the problems of low early strength of ecological concrete, failure to reach the external structure of buildings, low flexural and bending resistance, and achieve Accelerate the curing speed, improve the tensile properties, improve the effect of comprehensive mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

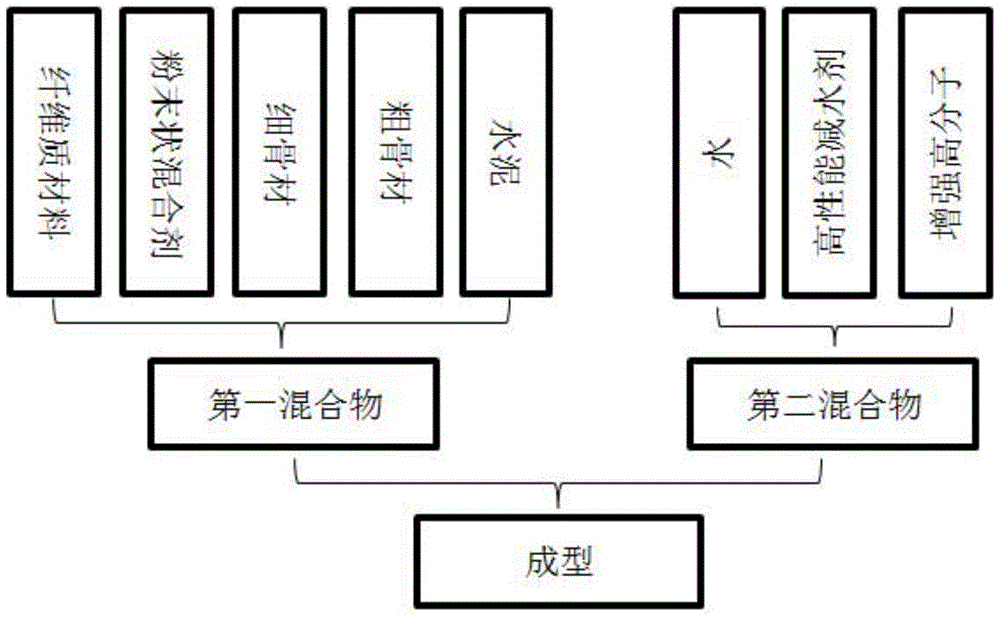

[0024] Such as figure 1 Shown, a kind of ecological concrete of the present invention is prepared from following raw materials:

[0025] The cement is ordinary Portland cement 525R (China Cement Factory of Nanjing Changjiang Cement (Group) Co., Ltd., Jiangsu Province); the coarse aggregate mainly refers to the dried gravel sludge with a particle size of about 2cm; the fine aggregate mainly refers to the particle size of 0.5 About cm of dried crushed stone sludge; the powder mixture is a hardening accelerator (triisoolamine, Sinopharm Chemical Reagent Co., Ltd.), and calcium silicate hydrate powder with a BET specific surface area of 100m2 / g is used as a carrier; The polymer material is EVA emulsion (Sichuan Vinylon Factory of Sinopec Group), with a solid content of 40%); the fibrous material is PVA fiber (Sichuan Vinylon Factory of Sinopec Group), with a diameter of 0.1 μm and a length of 3mm; the water reducing agent is M1 series high water-reducing polycarboxylate superp...

Embodiment 2

[0035] The raw materials for the preparation of a kind of ecological concrete in this embodiment are the same as those in Example 1. As shown in Table 1, the parts by weight of each raw material in this embodiment are: 100 parts of cement, 0.1 part of powdered admixture, 1 part of fibrous material, reinforced 2 parts of polymer agent, 480 parts of coarse aggregate, 50 parts of fine aggregate, 0.5 part of water reducer, 32 parts of water

[0036] The preparation method of the powdery mixture of this embodiment is the same as that of Embodiment 1.

[0037] The preparation method of the present embodiment ecological concrete is identical with embodiment 1.

[0038] 1) Add cement, coarse aggregate, fine aggregate, powdery mixture, and fibrous material into the stirring device and stir evenly for 30 seconds to form the first mixture;

[0039] 2) Stir and mix the high-performance water reducing agent, the reinforcing polymer agent and water to form a second mixture;

[0040] 3) St...

Embodiment 3

[0043] The raw materials for the preparation of a kind of ecological concrete in this embodiment are the same as in Example 1. As shown in Table 1, the parts by weight of each raw material in this embodiment are: 100 parts of cement, 1 part of powdery admixture, 1 part of fibrous material, reinforced 2 parts of polymer agent, 480 parts of coarse aggregate, 50 parts of fine aggregate, 0.5 part of water reducer, 32 parts of water

[0044] The preparation method of the powdery mixture of this embodiment is the same as that of Embodiment 1.

[0045] The preparation method of the present embodiment ecological concrete is identical with embodiment 1.

[0046] 1) Add cement, coarse aggregate, fine aggregate, powdery mixture, and fibrous material into the stirring device and stir evenly for 30 seconds to form the first mixture;

[0047] 2) Stir and mix the high-performance water reducing agent, the reinforcing polymer agent and water to form a second mixture;

[0048] 3) Stir the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com