A method for recovering acrylic acid from acrylic acid water

A technology of acrylic acid and acid water, applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problems of difficult biochemical treatment, high energy consumption, and difficult process, and achieve obvious price advantages, low energy consumption, and easy extraction high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

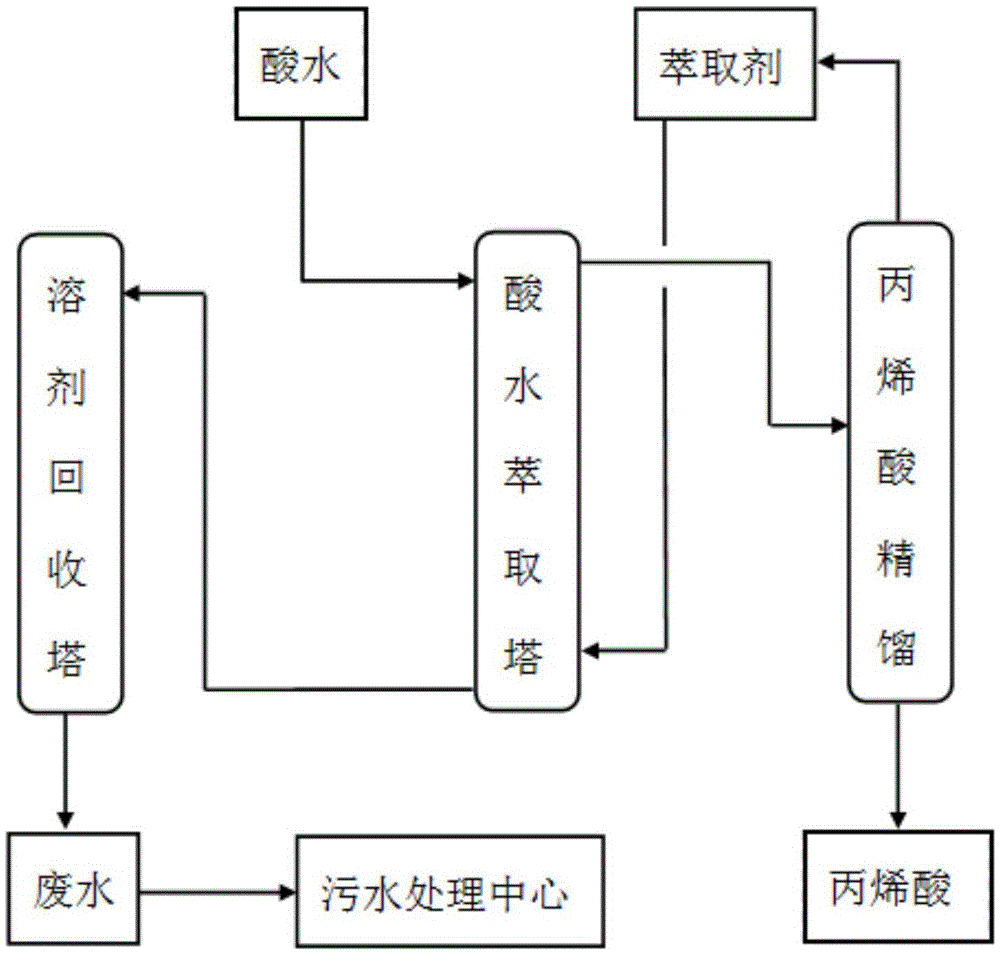

[0022] like figure 1 As shown, the propylene oxidation method is generally used in the production process of acrolein. While propylene is oxidized to form acrolein, a small part is deeply oxidized to acrylic acid. The reaction mixed product is washed, absorbed and rectified to obtain acrolein, and the by-product acrylic acid is dissolved in water in the washing and absorption process to generate acrylic acid water.

[0023] Acrylic acid water component and percentage content: acrylic acid is about 7%, acetic acid is about 0.5%, acrolein is about 500PPM, and the rest is water.

[0024] 1) The acrylic acid water is introduced into the extraction tower, the extraction agent is added, the extraction tower is operated at normal pressure and normal temperature, and the weight ratio of the acid water to the extraction agent is 1:0.7; the extraction tower is a rotary disk tower; the extraction agent is acetate; The concentration of acrylic acid in the phase is about 11%, and the acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com