Anti-aging agent composition, styrene type thermoplastic elastomer and preparation methods of anti-aging agent composition and styrene type thermoplastic elastomer

An anti-aging agent composition and styrene-based technology, applied in the field of styrene-based thermoplastic elastomers and their preparation, can solve the problems of environmental pollution and inability to significantly improve the aging resistance of styrene-based thermoplastic elastomers, and achieve improved aging resistance and The effect of anti-yellowing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

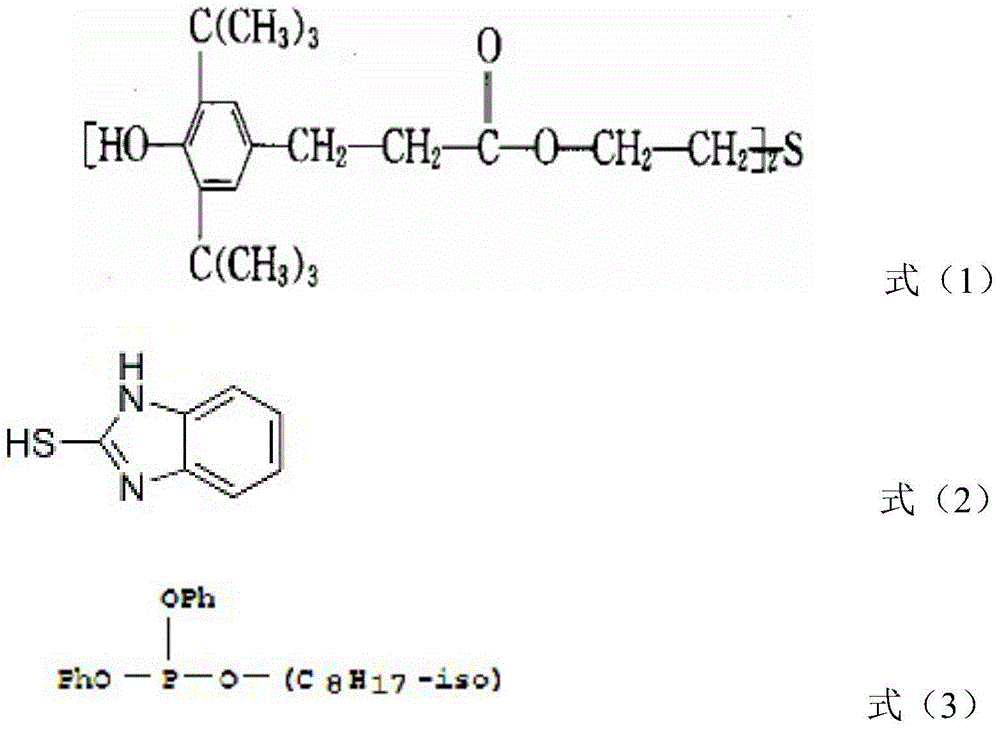

[0025] The present invention also provides a preparation method of anti-aging agent composition, the method comprises thiodiethylene bis[3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate], di Phenyl-isooctyl phosphite mixed with 2-mercaptobenzimidazole.

[0026] In order to make up the various substances in the anti-aging agent composition to be fully and uniformly mixed, and to facilitate addition and use, thiodiethylene bis[3-(3,5-di-tert-butyl-4-hydroxyphenyl) Propionate], diphenyl-isooctyl phosphite and 2-mercaptobenzimidazole mixed process are preferably carried out in the presence of an organic solvent, so that each material of the antioxidant composition is dissolved in the organic solvent , so as to make an organic solution of anti-aging agent composition. In order to obtain the antiaging agent composition product, the method may further include drying the organic solution of the antiaging agent composition.

[0027] In the present invention, the organic solvent may b...

Embodiment 1

[0041] This example is used to illustrate the preparation method of the antioxidant composition of the present invention.

[0042] At 40°C, 30 g of thiodiethylene bis[3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate], 80 g of 2-mercaptobenzimidazole, diphenyl-iso 10 g of octyl phosphite was dissolved in 120 g of acetone and mixed for 10 minutes until uniform, to obtain the antioxidant composition X1 dissolved in acetone.

Embodiment 2

[0044] This example is used to illustrate the preparation method of the antioxidant composition of the present invention.

[0045] At 50°C, thiodiethylene bis[3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] 60g, 2-mercaptobenzimidazole 50g, diphenyl-iso 30 g of octyl phosphite was dissolved in 560 g of acetone and mixed for 7 minutes until uniform, to obtain the antioxidant composition X2 dissolved in cyclohexane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com