High softening point asphalt granules for drilling fluid and preparation method thereof

A technology of high softening point asphalt and asphalt granules, applied in the field of petroleum asphalt, can solve the problems of difficult to continue to function, narrow operating temperature range, small viscoelastic range, etc., to increase the viscoelastic use range and reduce high temperature and high pressure filtration loss volume, the effect of increasing deformability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

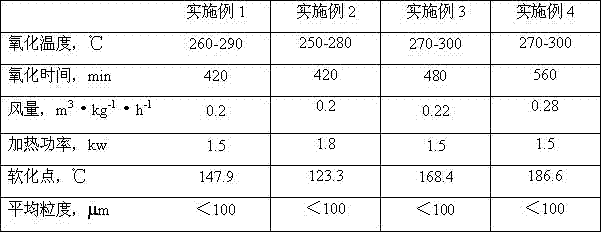

[0029] The vacuum residue with a penetration of 61 1 / 10mm at 25°C and a softening point of 46.3°C, accounting for 80.0% of the total (total mass of vacuum residue and coal tar pitch, the same below), is heated in an oxidation kettle To 140 ℃ molten state. Add coal tar pitch with a softening point of 65.4°C, accounting for 20.0% of the total amount, and heat it to 160°C in the premixing tank, then feed air and keep the pressure inside the tank at 0.12MPa for 20 minutes. Open the throttle valve, gradually spray the coal tar pitch liquid into the oxidation kettle, and adjust the air flow rate to 0.2m after spraying completely. 3 kg -1 h -1 , carry out blowing oxidation, oxidation conditions and product properties are shown in Table 1.

[0030] Add 100g of frozen high softening point asphalt (freezing conditions: temperature -25°C, time 8 hours) into a high-speed pulverizer, mix and grind for 25 seconds to obtain high softening point asphalt powder with an average particle size o...

Embodiment 2

[0032] Vacuum residue oil with a penetration of 82 1 / 10mm at 25°C and a softening point of 45.7°C, accounting for 75.0% (m) of the total, was placed in an oxidation kettle and heated to a molten state of 130°C. Add coal tar pitch with a softening point of 49.3°C in the premix tank, accounting for 25.0% (m) of the total amount, heat it to 150°C, feed air and keep the pressure inside the tank at 0.18MPa for 35 minutes. Open the throttle valve, gradually spray the coal tar pitch liquid into the oxidation kettle, and adjust the air flow to 0.20 m after spraying completely. 3 kg -1 h -1 , carry out blowing oxidation, oxidation conditions and product properties are shown in Table 1.

[0033] Add 100g of frozen high softening point asphalt (freezing conditions: temperature -30°C, time 10 hours) into a high-speed pulverizer, mix and grind for 20 seconds to obtain high softening point asphalt powder with an average particle size of 70 μm.

Embodiment 3

[0035] The vacuum residue with a penetration of 43 1 / 10mm at 25°C and a softening point of 48.5°C, accounting for 65.0% (m) of the total, was placed in an oxidation kettle and heated to a molten state of 150°C. Add coal tar pitch with a softening point of 56.2°C in the premix tank, accounting for 35.0% (m) of the total amount, heat it to 160°C, feed air and keep the pressure in the tank at 0.25MPa for 50 minutes. Open the throttle valve and gradually spray the coal tar pitch liquid into the oxidation kettle. After spraying completely, adjust the air flow rate to 0.22 m 3 kg -1 h -1 , carry out blowing oxidation, oxidation conditions and product properties are shown in Table 1.

[0036] Add 100g of frozen high softening point asphalt (freezing conditions: temperature -40°C, time 6 hours) into a high-speed pulverizer, mix and grind for 30 seconds to obtain high softening point asphalt powder with an average particle size of 50 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com