Method for brewing litchi waxberry sweet wine

A lychee and sweet wine technology, which is applied in the directions of microorganism-based methods, alcoholic beverage preparation, biochemical equipment and methods, etc., can solve the problem of not brewing full-juice sweet wine, etc., and achieve full-bodied, nutritious and elegant taste. delicate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

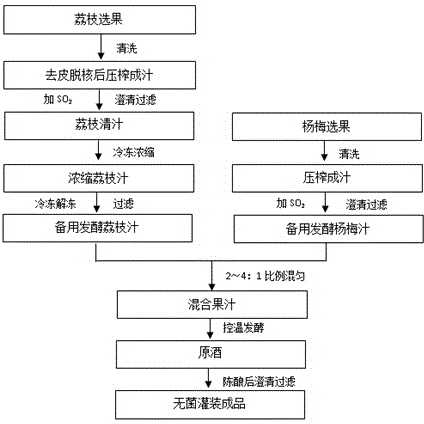

[0028] (1) Litchi raw material processing: select fresh lychee fruits with appropriate maturity, peel and remove the core, squeeze them into juice, and add 60 ppm SO 2 ;

[0029] (2) Freeze concentration: select the fresh lychee juice squeezed in step (1), add 400 ppm of PVPP to filter, and then freeze and concentrate at -6°C. When the sugar content of the juice reaches 240 g / L, stop the freeze concentration;

[0030] (3) Clarification: freeze and store the concentrated juice obtained in step (2) at -18°C for 24 hours, then thaw it, and then clarify it naturally to remove the precipitate;

[0031] (4) Red bayberry raw material processing: select fresh red bayberry fruits with a total acid content of 1-1.5 g / 100g and a total sugar content of 9-12 g / 100g, wash and squeeze into juice, and add 80 ppm SO 2 ;

[0032] (5) Mixing: Mix the concentrated lychee juice and red bayberry juice in a ratio of 2:1;

[0033] (6) Fermentation: add 200 ppm of domesticated fruit wine yeast, and...

Embodiment 2

[0042] (1) Litchi raw material processing: select fresh lychee fruits with appropriate maturity, peel and remove the core, squeeze them into juice, and add 60 ppm SO 2 ;

[0043] (2) Freeze concentration: select the fresh lychee juice squeezed in step (1), add 400 ppm of PVPP to filter, freeze and concentrate at -8°C, and stop freeze concentration when the sugar content of the juice reaches 260 g / L;

[0044](3) Clarification: freeze and store the concentrated fruit juice obtained in step (2) at -20°C for 36 hours, then thaw it out, clarify it naturally, and remove the precipitate;

[0045] (4) Red bayberry raw material processing: select fresh red bayberry fruits with a total acid content of 1-1.5 g / 100g and a total sugar content of 9-12 g / 100g, wash and squeeze into juice, and add 80 ppm SO 2 ;

[0046] (5) Mixing: Mix the concentrated lychee juice and red bayberry juice in a ratio of 4:1;

[0047] (6) Fermentation: Add 300 ppm of domesticated fruit wine yeast, and ferment...

Embodiment 3

[0056] (1) Litchi raw material processing: select fresh lychee fruits with appropriate maturity, peel and remove the core, squeeze them into juice, and add 60 ppm SO 2 ;

[0057] (2) Freeze concentration: select the fresh lychee juice squeezed in step (1), add 400 ppm of PVPP to filter, and then freeze and concentrate at -7°C. When the sugar content of the juice reaches 250 g / L, stop the freeze and concentrate;

[0058] (3) Clarification: The concentrated juice obtained in step (2) was frozen and stored at -19°C for 20 hours, then thawed, naturally clarified, and precipitated removed;

[0059] (4) Red bayberry raw material processing: select fresh red bayberry fruits with a total acid content of 1-1.5 g / 100g and a total sugar content of 9-12 g / 100g, wash and squeeze into juice, and add 80 ppm SO 2 ;

[0060] (5) Mixing: Mix the concentrated lychee juice and bayberry juice in a ratio of 3:1;

[0061] (6) Fermentation: Add 250 ppm of domesticated fruit wine yeast, and ferment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com