Preparation method for bismuth tungstate film

A bismuth tungstate thin film technology, which is applied in the coating process of metal materials, etc., can solve the problems of bismuth tungstate thin film adhesion and poor photoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A method for preparing a bismuth tungstate thin film, wherein a substrate is placed in a reaction solution to generate a hydrothermal reaction to form a bismuth tungstate thin film on the surface of the substrate, wherein the substrate is a tungsten plate or a substrate with a tungsten layer formed on the surface. The reaction solution is an acidic solution containing bismuth ions. Specifically include the following steps:

[0022] S1: cleaning the substrate.

[0023] The base is a tungsten plate or a substrate with a tungsten layer formed on the surface.

[0024] In particular, the thickness of the tungsten plate is 0.2mm-2mm. Preferably, the thickness of the tungsten plate is 0.5 mm.

[0025] The substrate with the tungsten layer formed on the surface is obtained by depositing tungsten on substrates such as conductive glass by sputtering, evaporation or other methods. In particular, the thickness of the tungsten layer is 0.001mm-2mm.

[0026] In particular, the c...

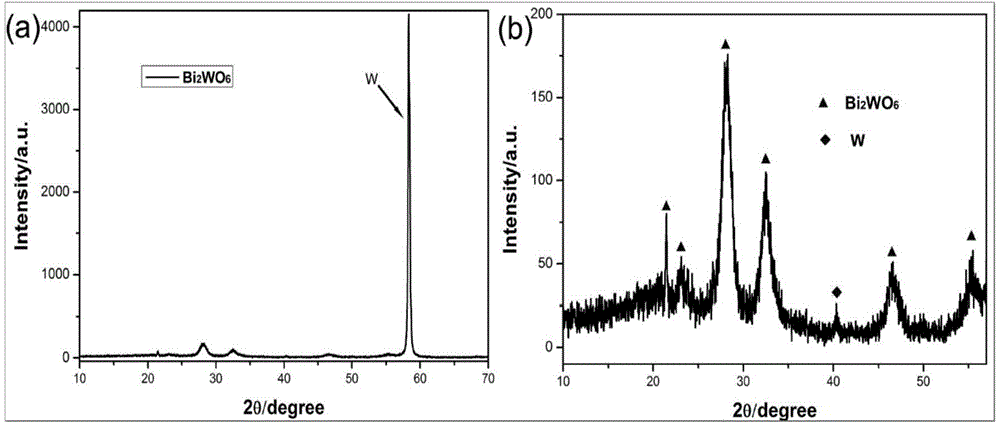

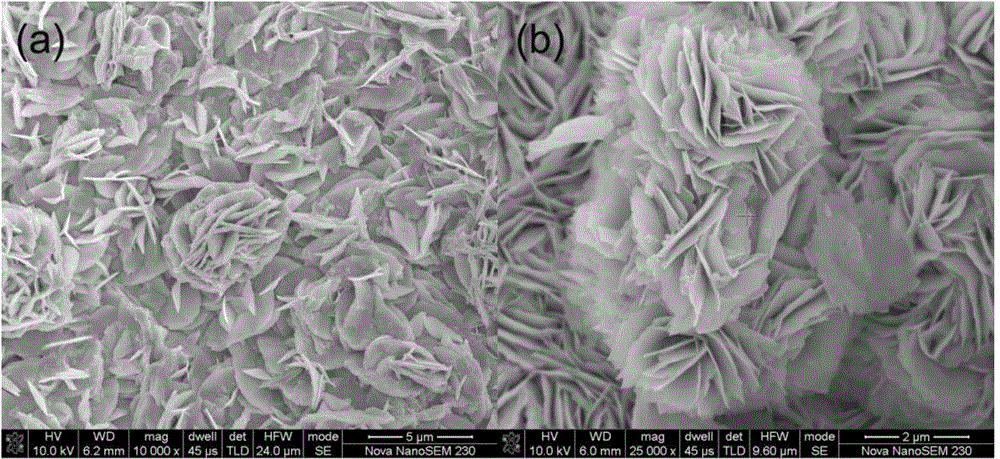

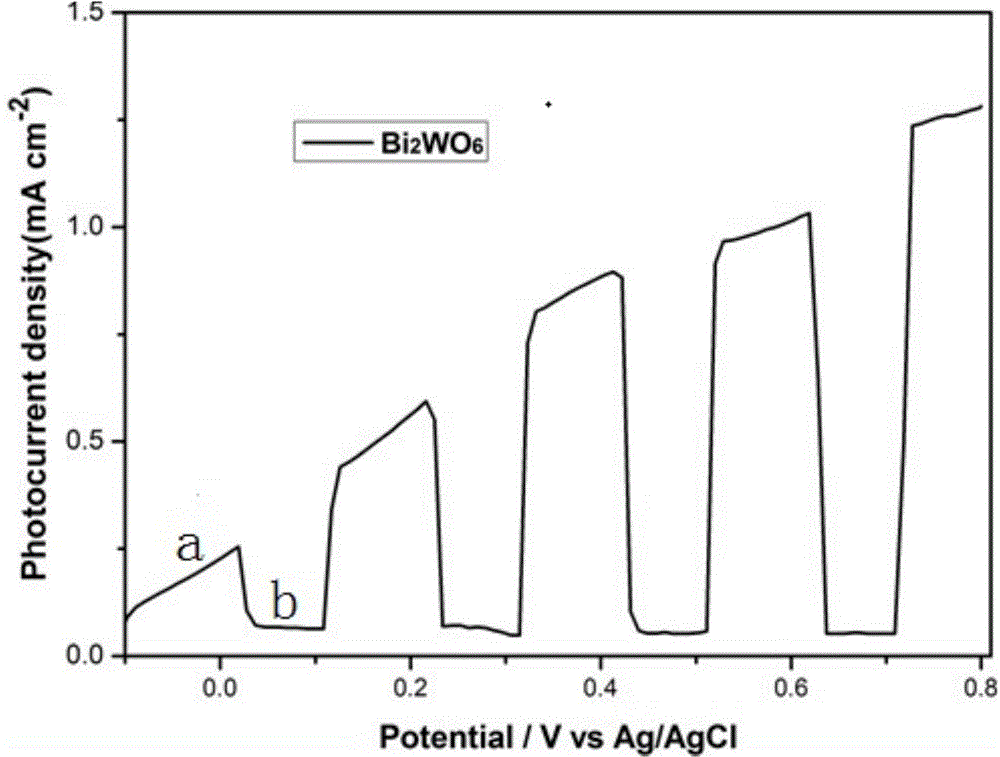

Embodiment 1

[0039] After cleaning the tungsten plate with a thickness of 0.5mm, it is ready for use. 0.1g of Bi(NO 3 ) 3 ·5H 2 O was added to 50 mL of nitric acid solution with a concentration of 1mol / L, stirred, and fully dissolved to obtain a nitric acid solution of bismuth salt; place the cleaned tungsten plate in the lining of the reaction kettle, and then pour the nitric acid solution of bismuth salt into the reaction kettle 180°C for 12 hours; when the reactor was cooled to room temperature, take it out, wash it with ethylene glycol and water for 2-3 times, and dry it at 200°C for 6 hours to obtain a bismuth tungstate film.

Embodiment 2

[0041] After cleaning the tungsten plate with a thickness of 0.2mm, it is ready for use. 0.025g of Bi(NO 3 ) 3 ·5H 2 O was added to 50mL of nitric acid solution with a concentration of 0.2mol / L, stirred, and fully dissolved to obtain the nitric acid solution of bismuth salt; the cleaned tungsten plate was placed in the inner lining of the reaction kettle, and then the nitric acid solution of bismuth salt was poured into the reaction In the kettle, react at 250°C for 0.5 hours; when the reaction kettle is cooled to room temperature, take it out, rinse with ethylene glycol and water for 2-3 times, and dry at 250°C for 1 hour to obtain a bismuth tungstate film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com