Low oil consumption type engine crankcase and engine set

An engine, low fuel consumption technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems such as affecting fresh air delivery, unfavorable muffler conversion reaction, etc., to improve effective utilization, reduce unnecessary consumption, reduce The effect of production and assembly costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

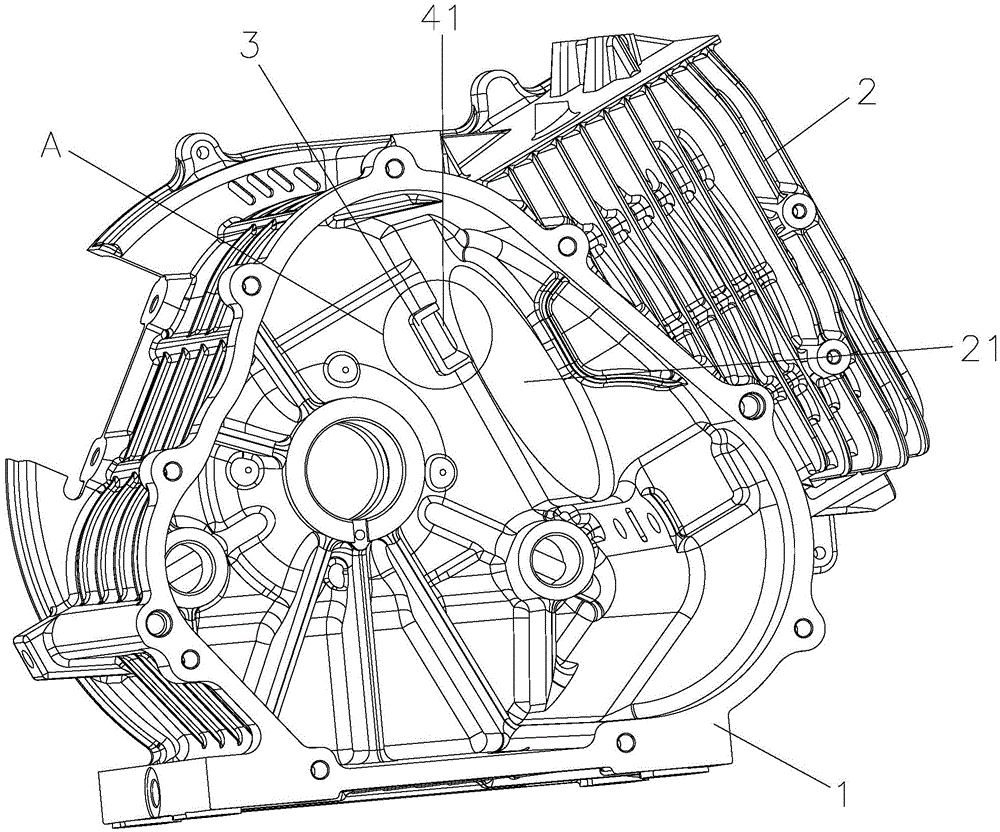

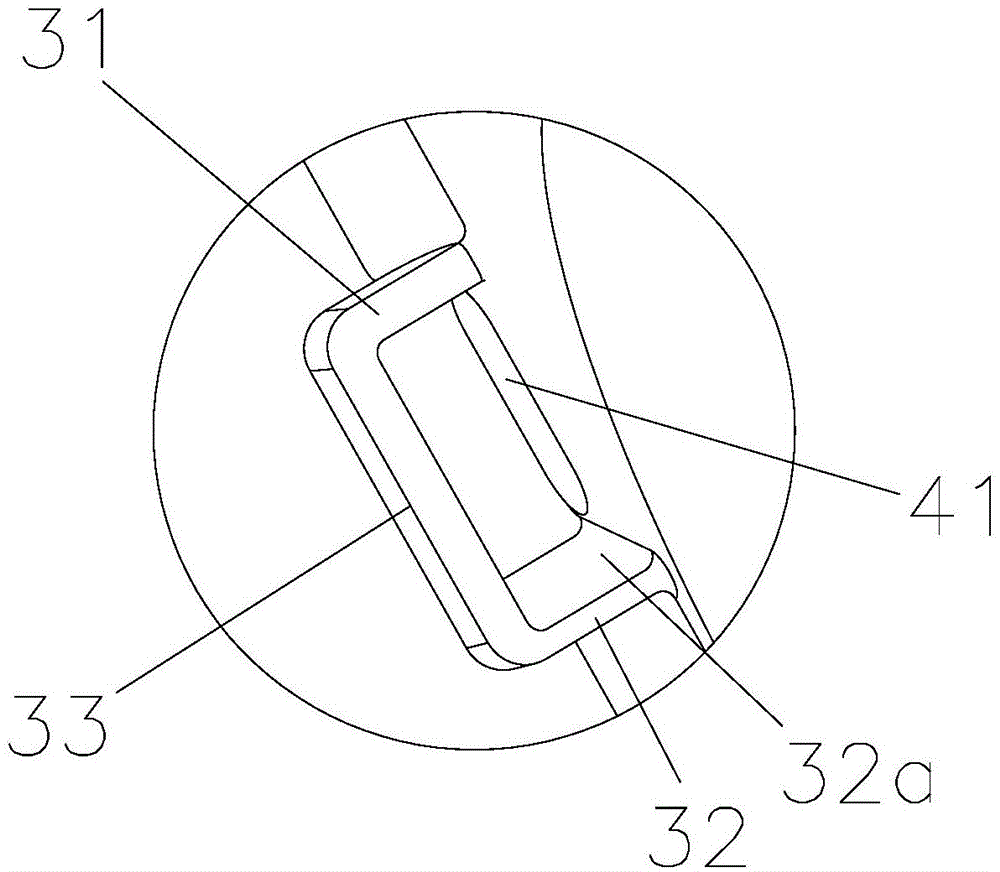

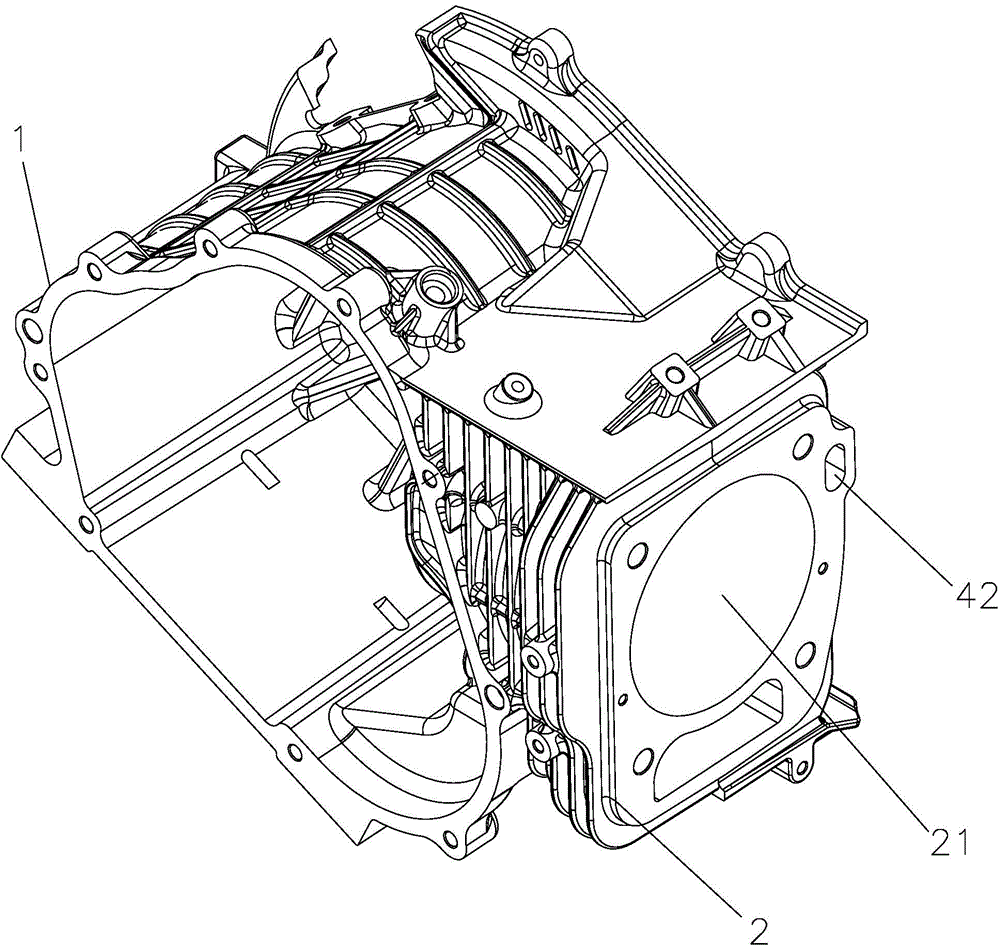

[0023] figure 1 It is a schematic diagram of the three-dimensional structure of the present invention, figure 2 for figure 1 Enlarged view of A in the middle, image 3 It is a schematic diagram of the three-dimensional structure of another angle of the present invention, as shown in the figure: the low fuel consumption type engine casing and the engine thereof of the present invention include a crankcase 1, a cylinder head 2 and a cylinder 21, and the inner chamber of the crankcase 1 passes through The air passage (not shown in the figure) communicates with the rocker chamber at the upper end of the cylinder head 2, and the inner cavity is provided with an oil baffle 3 for preventing splashed oil from entering the air passage. The air passage is inclined to the oil storage chamber. The cylinder head 2 is assembled on the upper end of the cylinder 21 of the box body, the cylinder head cover (not shown in the figure) is assembled on the upper end of the cylinder head 2, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com