Six-color transfer printing machine used for processing glass-ceramic products

A technology for glass ceramics and pad printing machines, which can be used in printing machines, rotary printing machines, screen printing machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

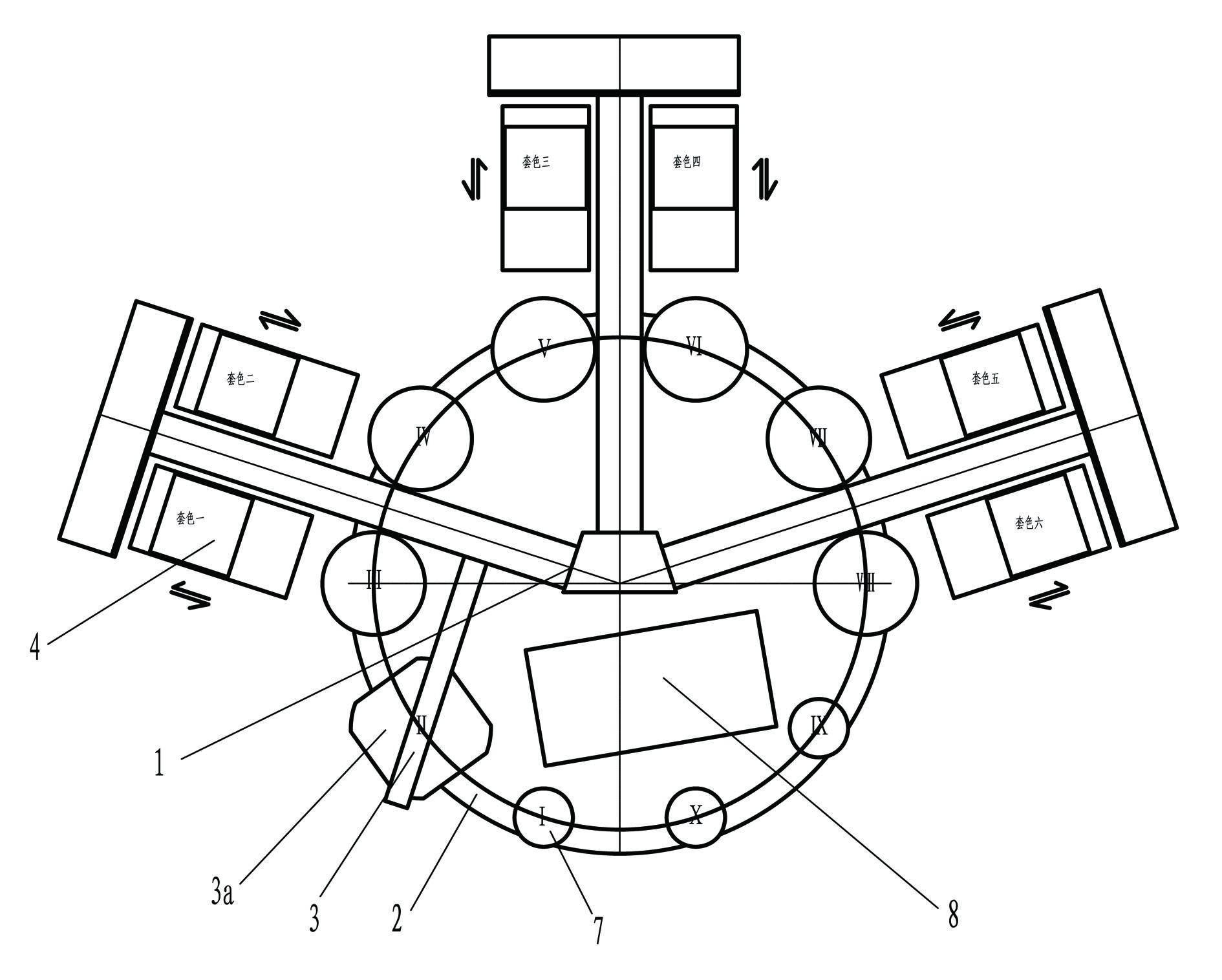

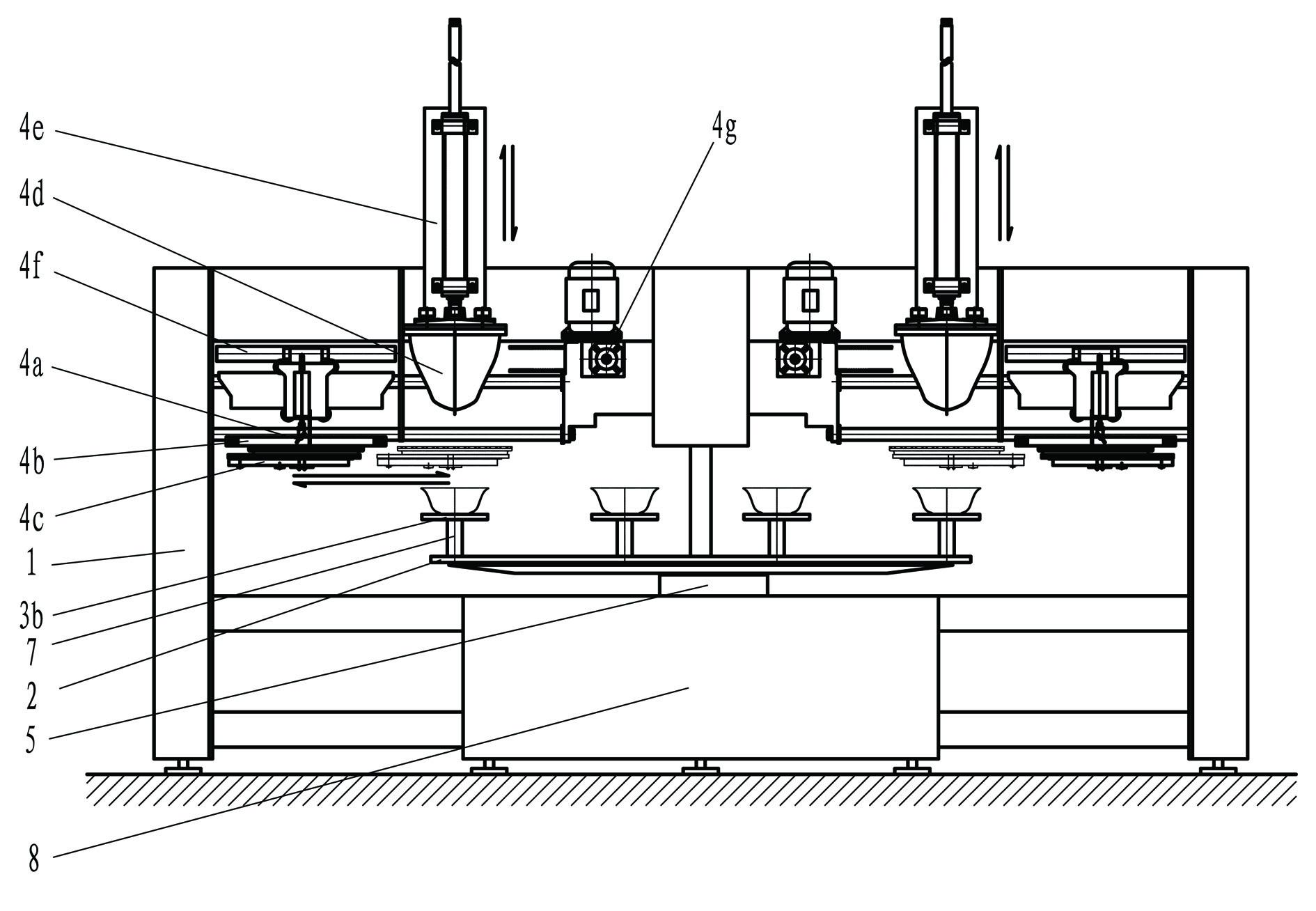

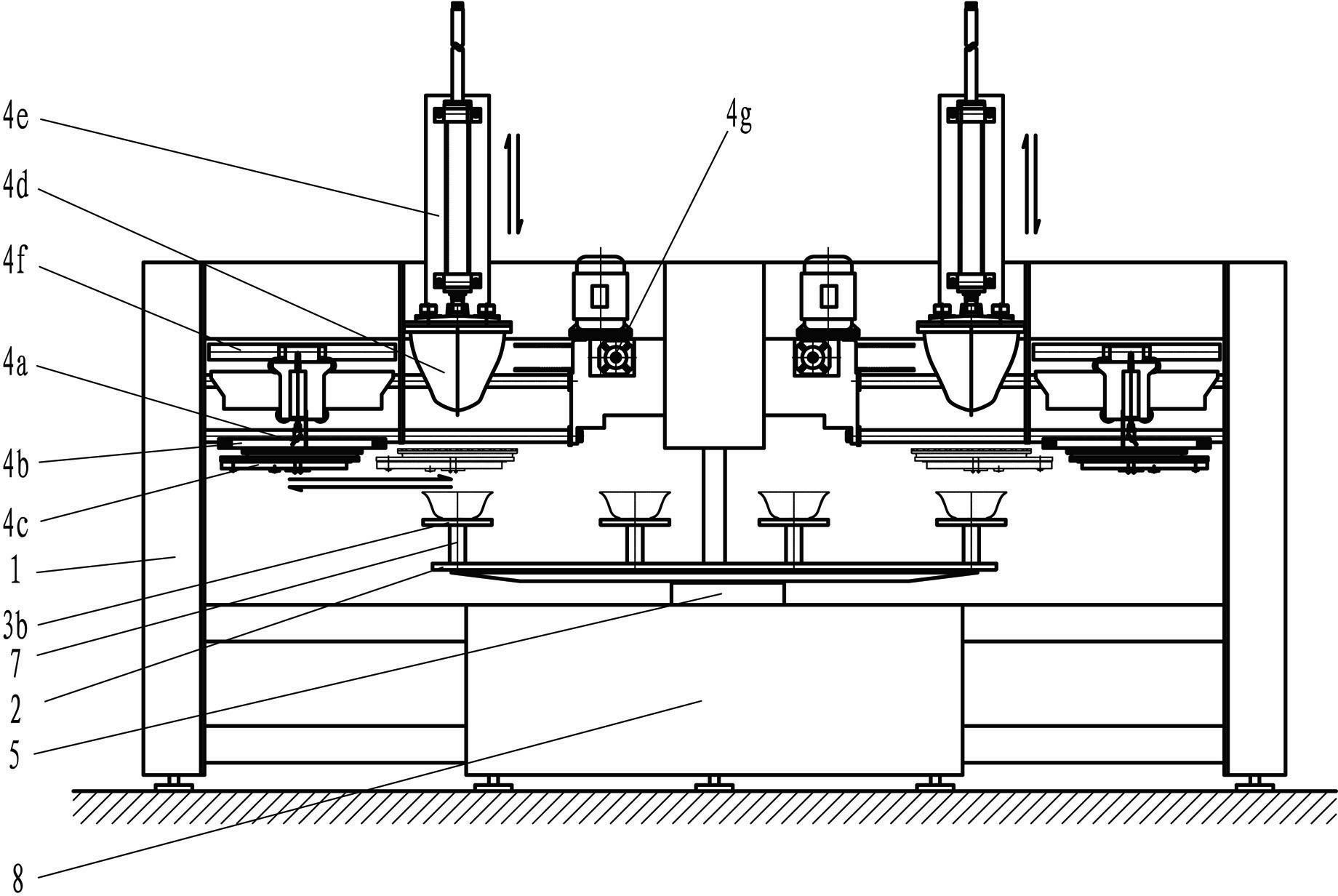

[0012] Such as figure 1 , figure 2 The shown embodiment of the six-color pad printing machine of the present invention for processing glass ceramic products includes a machine platform 1 placed on the ground, in which an electric control cabinet 8 for automatic detection and control operation is arranged, and the machine platform 1 There is a rotating frame 2 with intermittent movement. The machine 1 drives the rotating frame 2 through an arc cam indexing mechanism 5 to realize the intermittent movement of the rotating frame 2. There are multiple stations for placing glass ceramic workpieces on the rotating frame 2 7 and the workpiece positioning device 3 that cooperates with the station, the station 7 rotates intermittently with the rotary frame 2, the workpiece positioning device 3 of the present embodiment includes a clamp 3a placed in the machine platform 1 above the station, and a clamp 3a placed in the station 7 The suction cup seat 3b at the bottom, when the glass-cer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com