Denoising volute for enlarging outlet area of centrifugal fan

An outlet area, centrifugal fan technology, applied in the components of the pumping device for elastic fluids, mechanical equipment, machines/engines, etc., can solve the problems of increased flow loss, large flow loss, inconvenient pipe network, etc. Small size, reduced fan noise, and easy layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

test approach 1

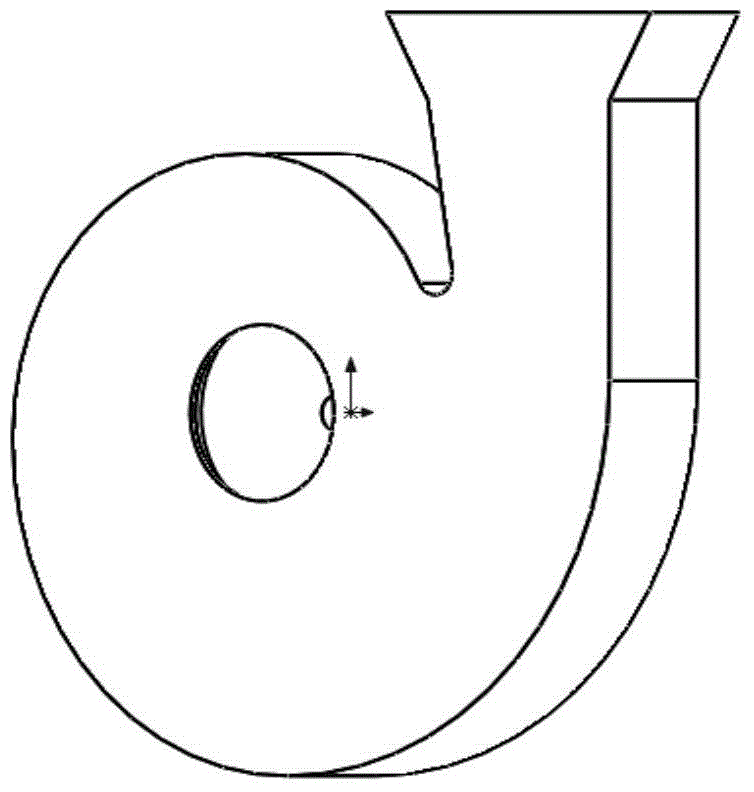

[0018] Test plan one (traditional structure fan):

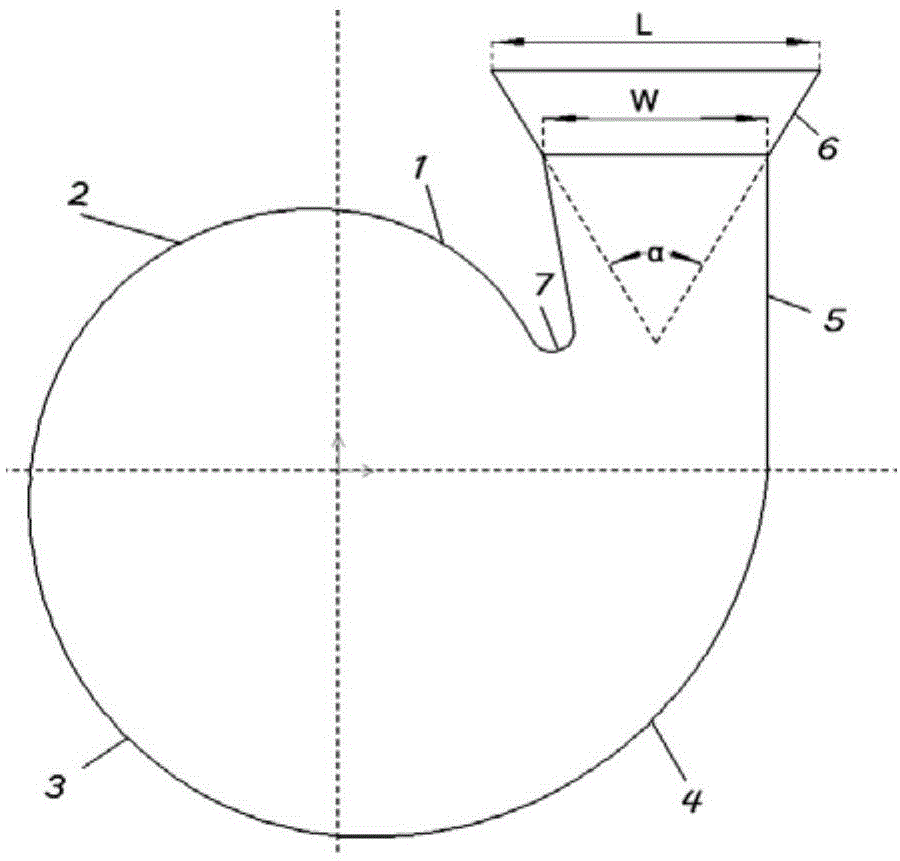

[0019] Carry out modeling according to the 6-31 fan aerodynamic sketch, the fan model with a modeling ratio of 8, the outlet of the fan is connected to the additional connecting pipe 6, the inlet of the connecting pipe matches the outlet of the fan (width W is 412.8mm), and the outlet of the connecting pipe The width L is 600mm, and the expansion angle α of the connecting pipe is 120°. The results are listed in Table 1

test approach 2

[0020] Test scheme two (the fan with the structure of the present invention)

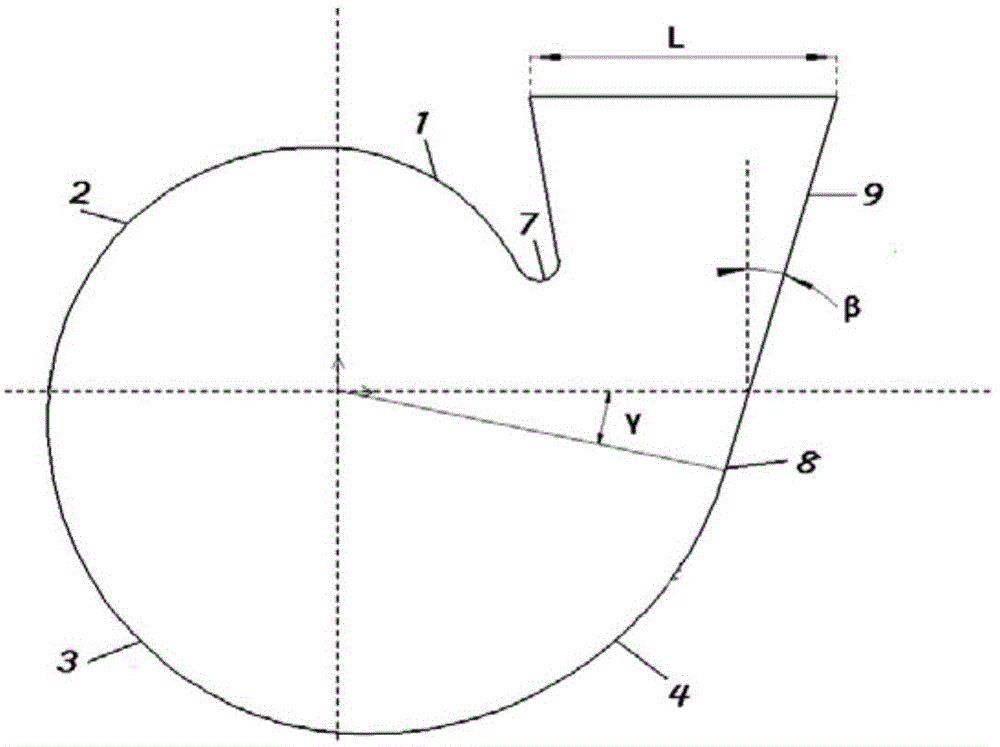

[0021] Based on the fan model modeled according to the aerodynamic sketch of 6-31 fan with a modeling ratio of 8, the volute tongue, the first circular arc, the second circular arc, and the third circular arc are kept unchanged, and the advanced The opening tangent point and the structure of the inclined outlet straight section are used to increase the outlet (width L) of the volute, so that the deflection angle β of the inclined outlet section straight line to the opposite direction of the airflow is 16.7°. The results are listed in Table 1.

[0022] Table 1

[0023] Test program

[0024] From the comparative data in Table 1, it can be seen that, compared with the traditional volute with an additional connecting pipe, the fan outlet optimized by the present invention has improved fan total pressure and efficiency, and reduced fan noise. Therefore, the present invention solves the technic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com