Two-free-curved-surface optical lens used for ultrathin direct-lit type LED backlight system

A technology of backlight system and curved surface lens, which is applied in the field of double free-form surface optical lens, can solve problems such as difficult to meet uniform illumination, inability to accurately control the angular distribution of light intensity, dark spots, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The implementation of the present invention will be described in detail below with reference to the drawings and embodiments, but the implementation of the present invention is not limited thereto.

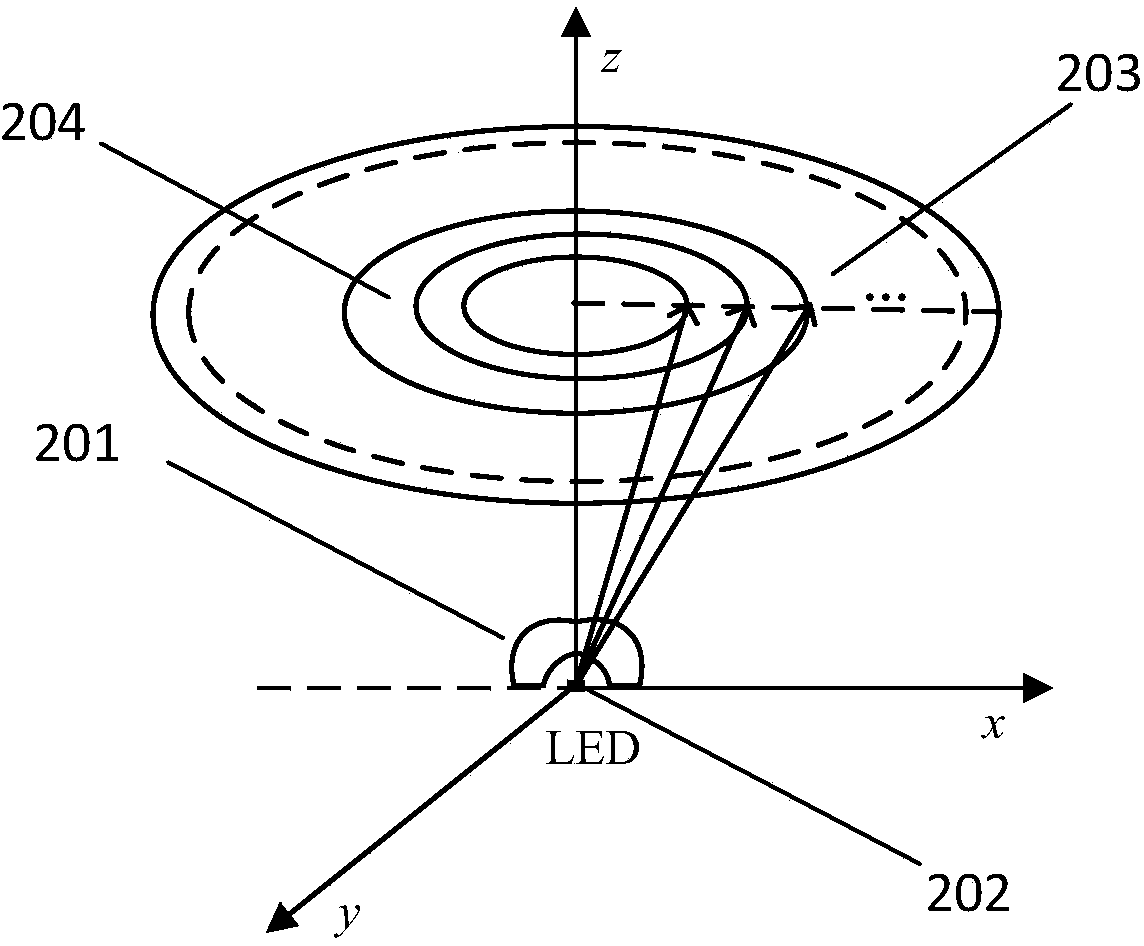

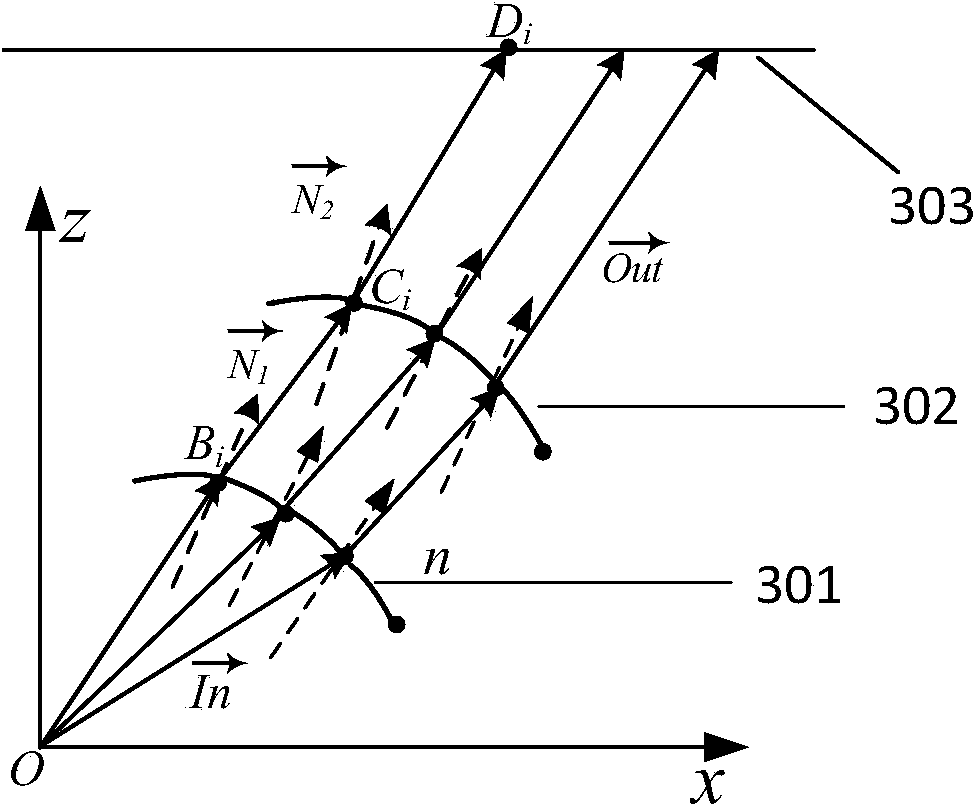

[0059] A double free-form surface optical lens for ultra-thin direct LED backlight system, the lens is made of transparent material, the transparent material is optical glass or PMMA or PC, the lens includes two free-form surfaces, respectively constitute the incident surface and the exit surface . There is a cavity in the center of the bottom surface of the lens for installing the LED therein. The wall of the cavity is a free-form surface, which constitutes the incident surface; the outer surface of the lens is also a free-form surface, which constitutes the outgoing surface.

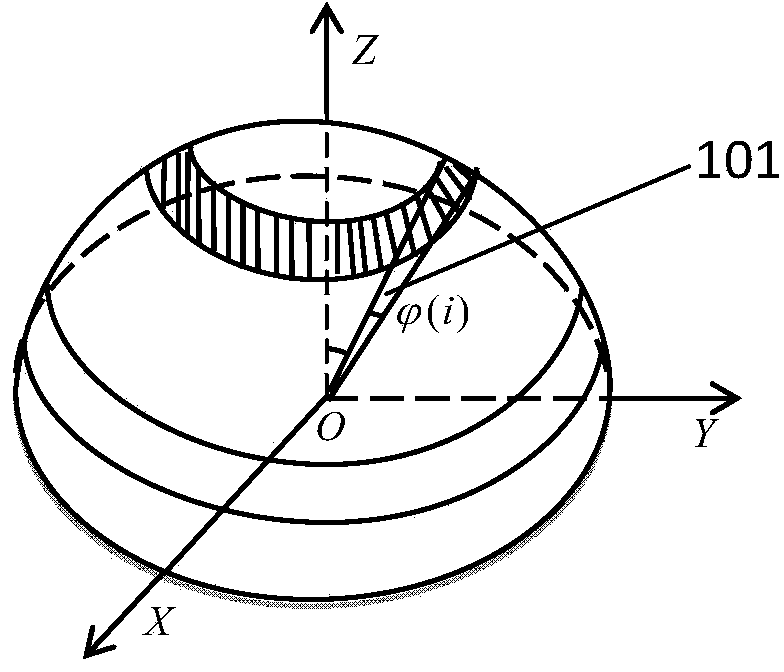

[0060] 1. Set the initial conditions and divide the solid angle of the LED light source.

[0061] First, the distance between the target lighting surface and the LED is 12mm, the target lighting ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com