Device and method for testing interfacial tension and contact angle by adopting spinning drop method under ultrahigh pressure and at high temperature

A technology of interfacial tension and ultra-high pressure, applied in the direction of surface tension analysis, measuring devices, surface/boundary effects, etc., can solve the problems of reducing droplet movement, non-similar test methods, and no protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

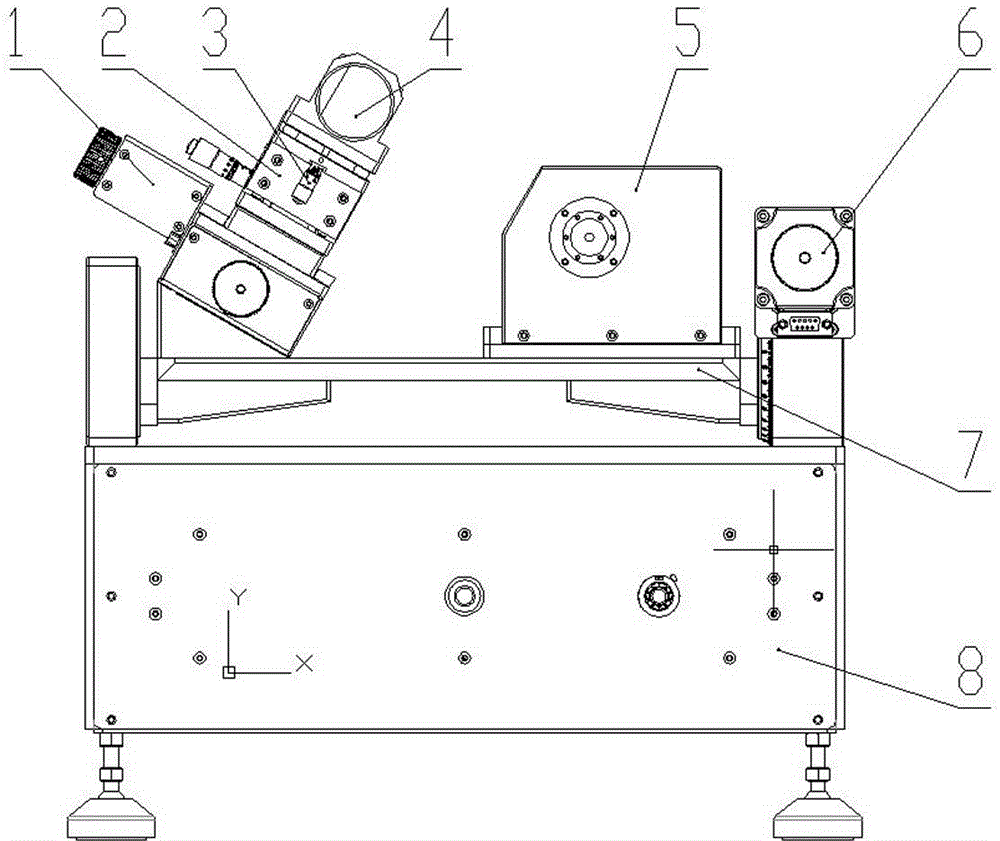

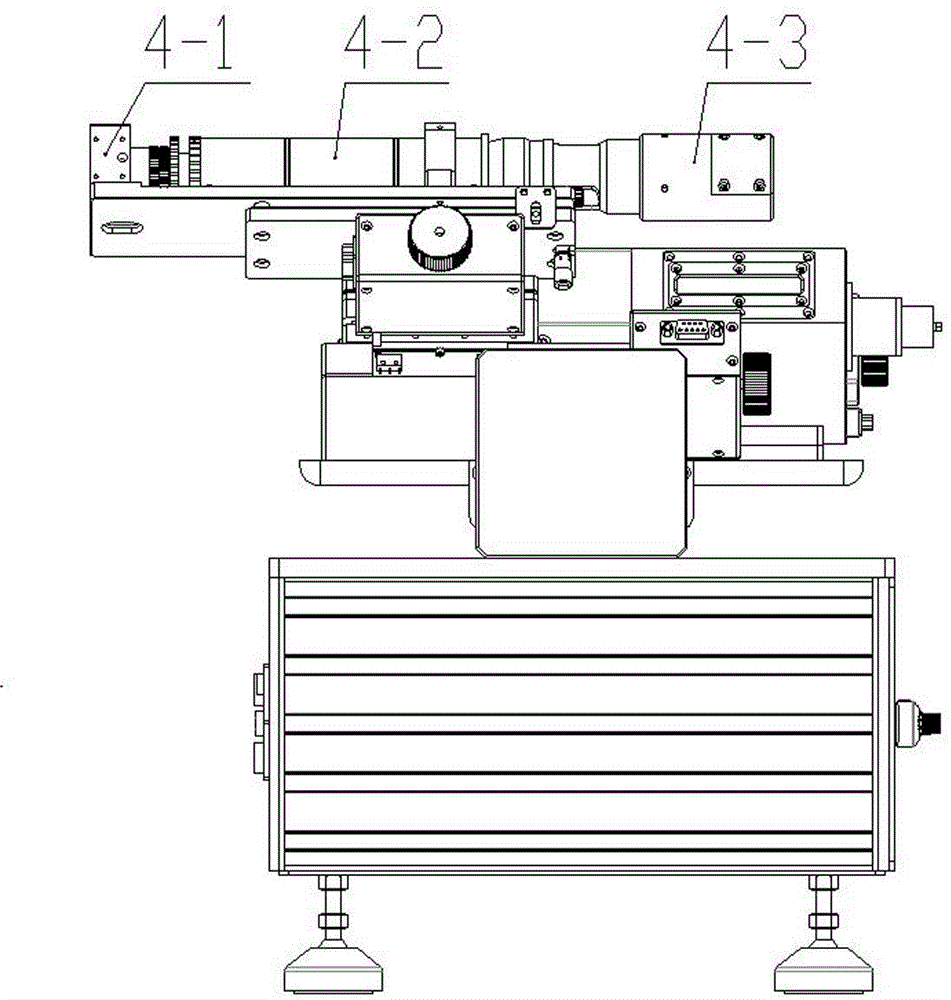

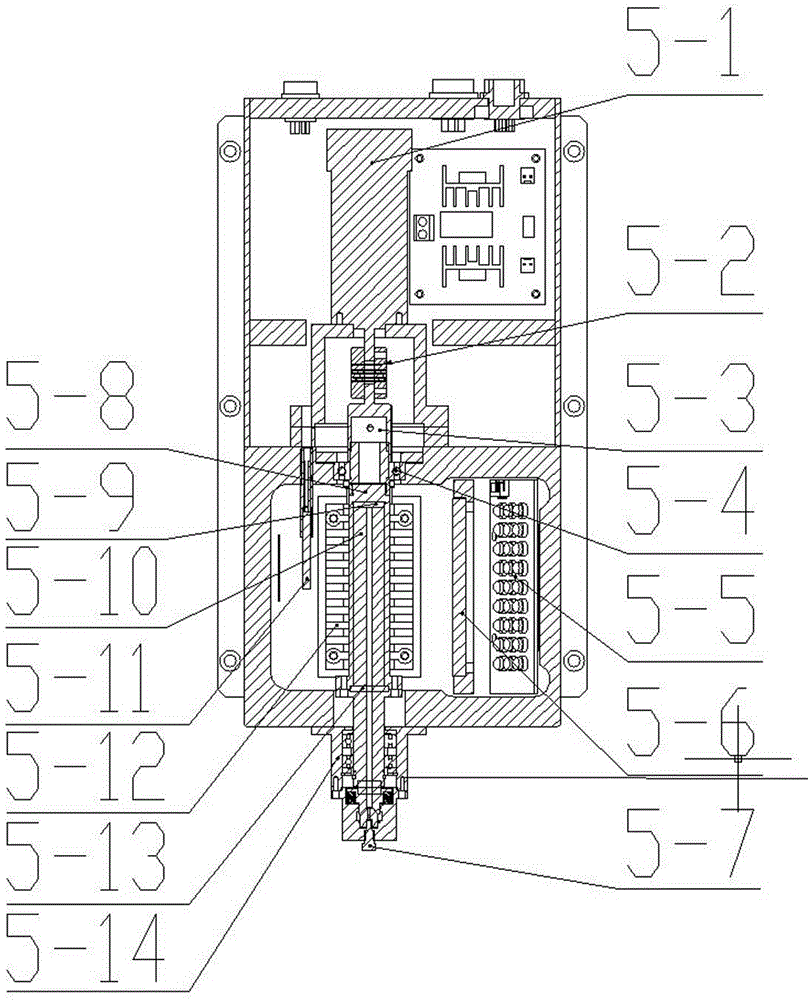

[0151] In order to achieve 15,000RPM speed under the condition of canceling the pulley conversion, control the sample temperature with high precision and effectively eliminate the temperature rise caused by bearing and air agitation, the sample tube is self-sealing and easy to clean, and the image of the rotating droplet is acquired conveniently and accurately , Quickly and accurately test the interfacial tension and contact angle values of rotating droplets. This patent constructs the following method and structural system, and proposes a method and method to obtain the interfacial tension and contact angle values by using the rotating droplet profile analysis technology. A set of devices:

[0152] 1. Design a set of rotating drop sample tube and its sealing structure with ultra-high pressure and high-speed rotary joint to achieve self-sealing of the sample tube and maintain high pressure and high temperature. The main methods are as follows:

[0153] (1) One end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com