Ammonia gas monitoring alarming and switching system and method based on chromatographic analysis

A chromatographic analysis and switching system technology, applied in the field of gas detection and alarm, can solve the safety hazards of on-site production staff, the quality of desilane products, etc., achieve high application and promotion significance, avoid environmental pollution problems, and flexibly select and switch Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

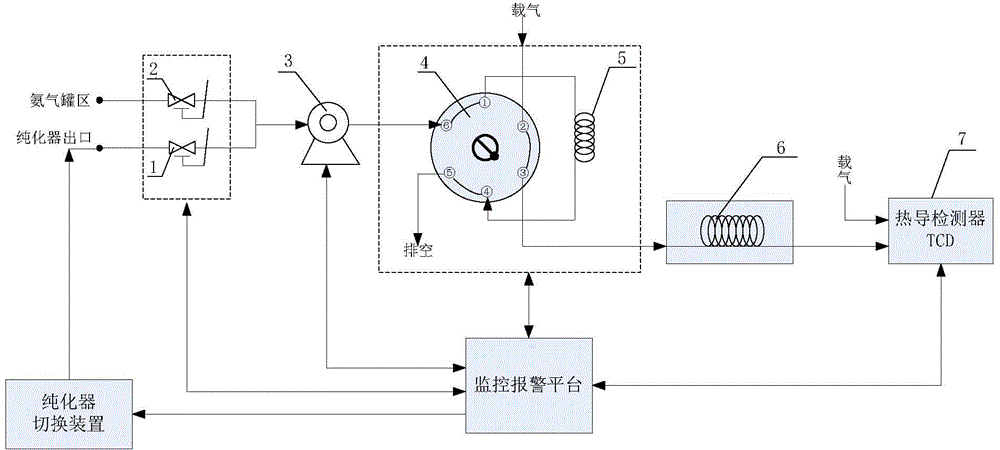

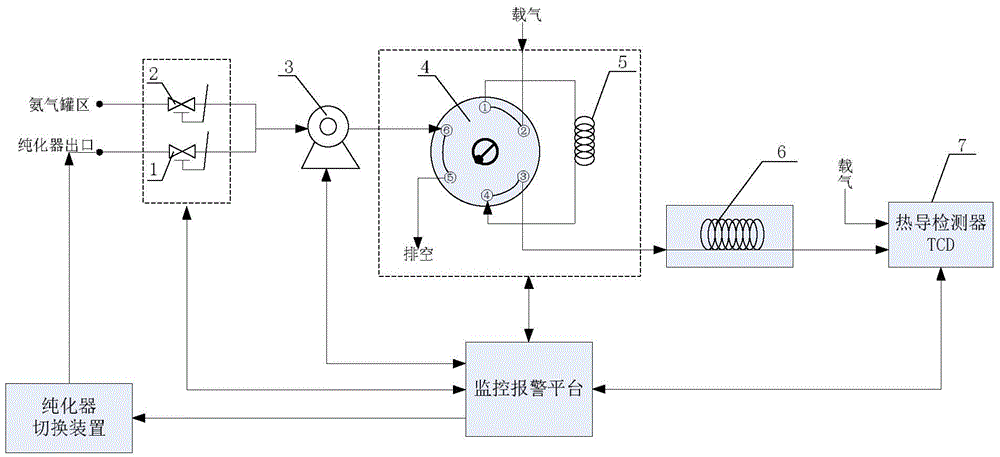

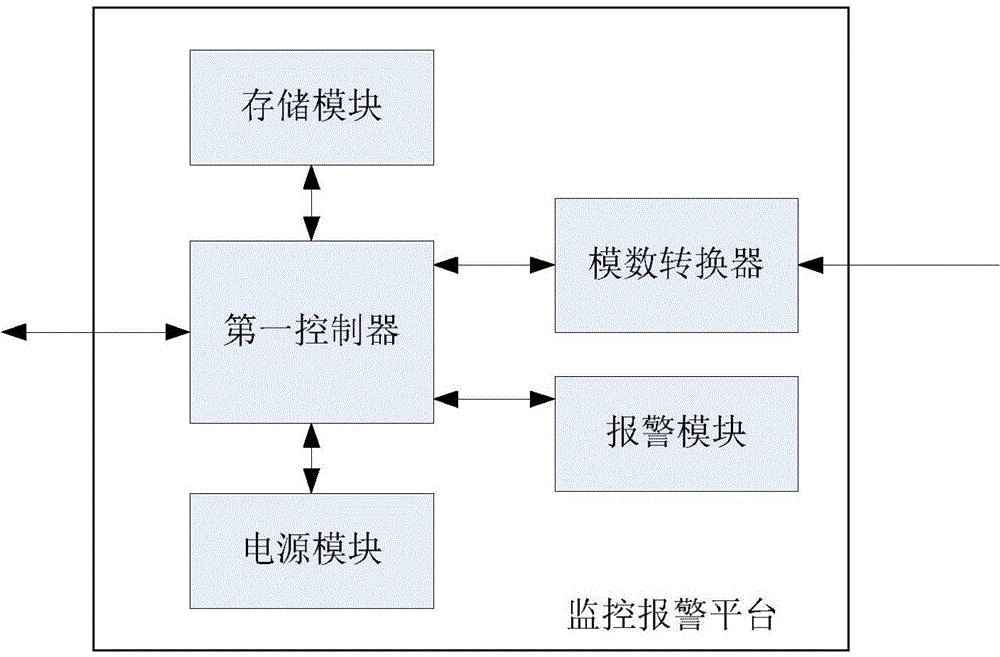

[0035] System embodiment 1: such as figure 1 and figure 2 As shown, the ammonia monitoring alarm and switching system based on chromatographic analysis provided by Embodiment 1 of this system includes the intake pipe of the first monitoring point, the intake pipe of the second monitoring point, the sampling gas pump 3, the six-way flat valve, the chromatographic column 6, Thermal conductivity detector 7, monitoring alarm platform and purifier switching device; the six ports of the six-way planar valve are numbered clockwise in sequence: port one to port six; the ports of the six-way planar valve A quantitative tube 5 is connected between the first port and the fourth port.

[0036] The inlet pipe of the first monitoring point is arranged at the outlet of the purifier, and the inlet pipe of the second monitoring point is arranged in the ammonia tank area. The inlet pipe of the first monitoring point communicates with the sampling air pump through the first electromagnetic va...

Embodiment 2

[0042] System embodiment 2: The ammonia gas monitoring alarm and switching system based on chromatographic analysis provided by this embodiment includes the first monitoring point intake pipe, sampling gas pump, six-way flat valve, chromatographic column, thermal conductivity detector, monitoring and alarm platform and Purifier switching device; the six ports of the six-way planar valve are numbered clockwise in sequence: port one to port six; a quantitative tube is connected between port one and port four of the six-way planar valve ;

[0043] The inlet pipe of the first monitoring point communicates with the sampling gas pump through the first electromagnetic valve; the output of the sampling gas pump communicates with port 6 of the six-way planar valve; port 2 of the six-way planar valve communicates with the carrier gas pipe, Port five is connected to the emptying pipe; port three of the six-way planar valve and the monitoring and alarm platform are sequentially connected ...

Embodiment 3

[0049] System Embodiment 3: The structure is basically the same as any one of System Embodiment 1 and System Embodiment 2, and the similarities will not be described again. The difference is that it includes two or more monitoring point intake pipes, each The intake pipes of the monitoring points are connected with the sampling air pumps through their corresponding solenoid valves; the pneumatic multi-way valves can be configured between each solenoid valve and the sampling air pumps according to the actual structure for the selection of the intake pipes of the monitoring points. The electromagnetic valves connected to the air intake pipes of the monitoring points are all connected to the circuit of the monitoring and alarm platform.

[0050] The purifier switching device includes a mixed gas inlet, a second controller and more than two groups of purifiers; the inlets of each group of purifiers communicate with the mixed gas inlet through their corresponding electromagnetic val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com