A single-fiber multi-directional optical component

An optical component and single-fiber technology, which is applied in the field of single-fiber multi-directional optical components, can solve the problems of reduced coupling efficiency, increased difficulty of coupling process, and high difficulty of automated production, reducing the requirements for installation position accuracy and saving technical costs and time cost, and the effect of avoiding mutual interference of electromagnetic signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

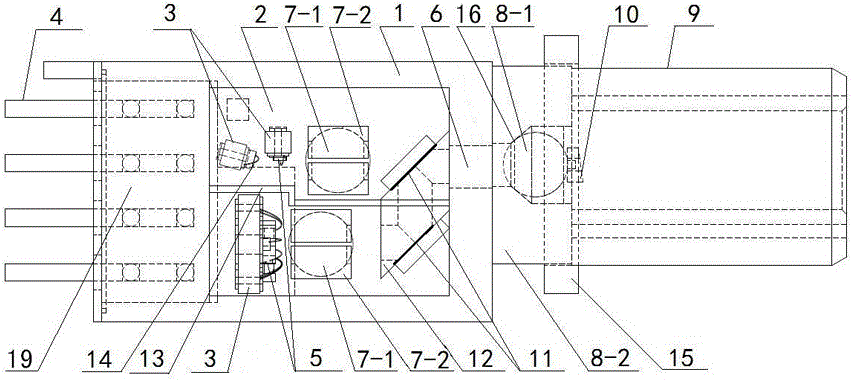

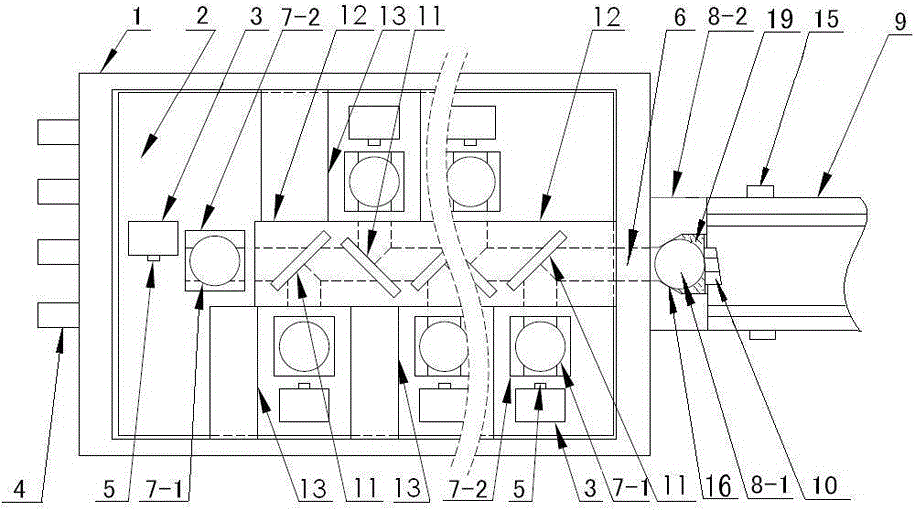

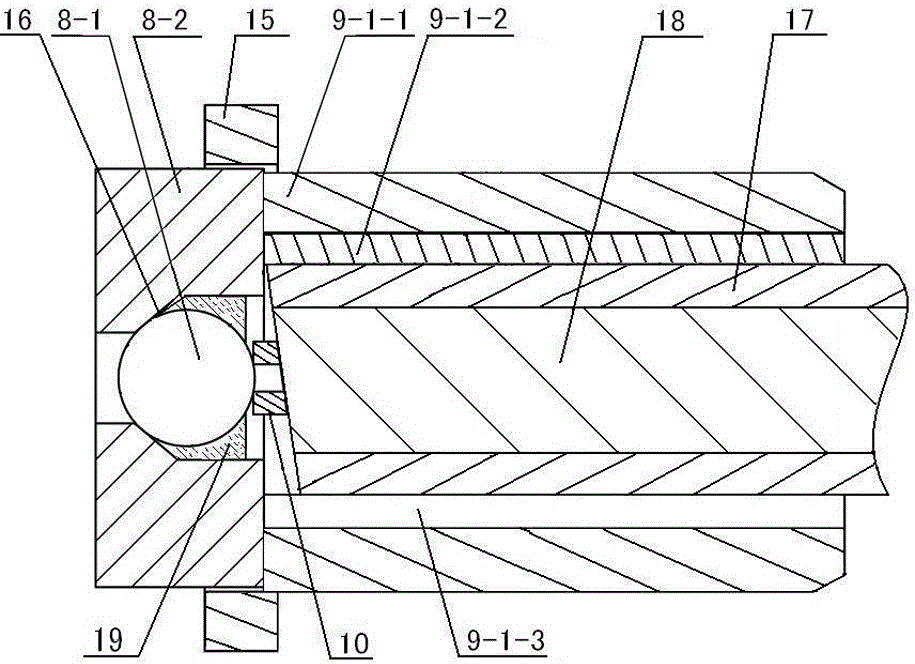

[0065] like figure 1 and Figure 3~7 As shown, embodiment 1: it includes a housing 1, an optical interface component arranged on the housing 1, a main base 2 and a chip support base 3 fixed in the housing 1, respectively arranged on two chips The detector chip and its auxiliary circuit on the support base 3, the laser chip and its auxiliary circuit, and the two chip-end lenses 7-1 correspondingly arranged on the main base 2; one side of the housing 1 has a light-through The hole 6, the optical interface part is aligned with the light hole 6 on the housing 1; the chip support base 3 is welded or glued on the main base 2;

[0066] The two chip-side lenses 7-1 are respectively on the photosensitive surface of the detector chip and the front end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com