Dry type transformer bladeless cooling fan with photovoltaic conversion function and method of dry type transformer bladeless cooling fan

A dry-type transformer and photovoltaic conversion technology, which is applied in the direction of transformer/inductor cooling, photovoltaic power generation, photovoltaic modules, etc., can solve the problems of the influence of wind force in the environment, difficult maintenance and cleaning, unsafe wind blades, etc., to improve overload and Short-circuit resistance, low noise, and less maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

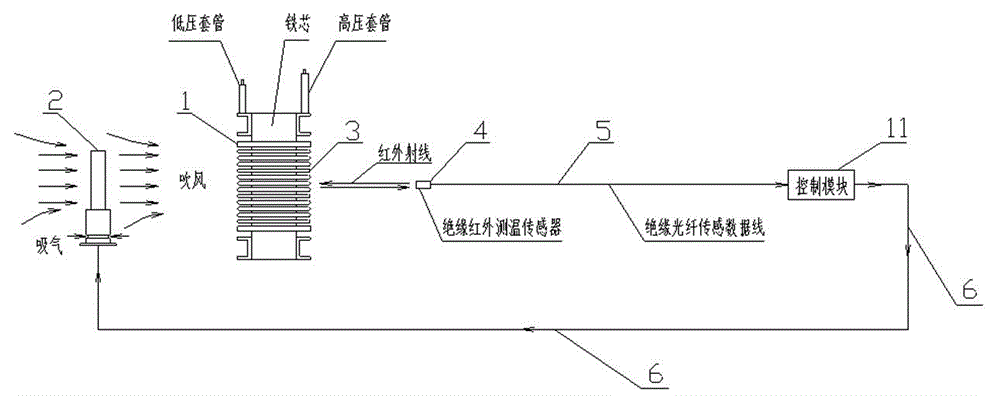

[0030] Please refer to image 3 , the present invention provides a dry-type transformer bladeless cooling fan with photovoltaic conversion function, which is characterized in that: it includes a dry-type transformer 1, and a bladeless cooling fan 2 is arranged directly opposite to the dry-type transformer 1. The bladeless cooling fan 2 is connected with a control module 11, and the control module 11 is connected with an infrared temperature sensor 4, please refer to Figure 8 , the infrared temperature sensor 4 includes a sensor and a temperature probe, continue to refer to image 3 , the temperature measuring probe is arranged near the dry-type transformer 1 and facing the dry-type transformer winding 3, and the dry-type transformer 1 is also connected to a photovoltaic conversion system for power supply;

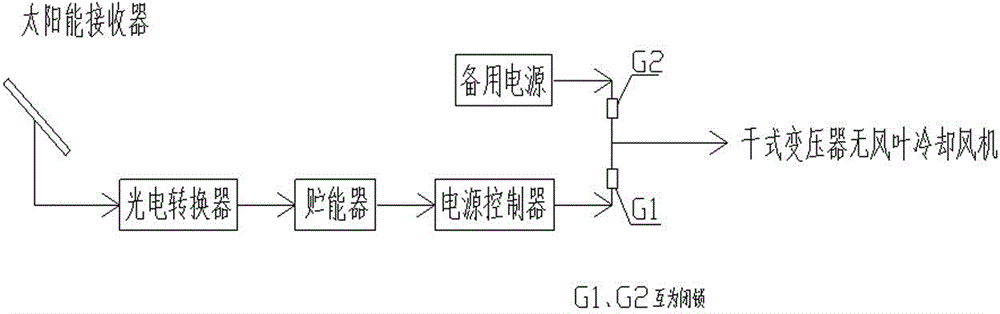

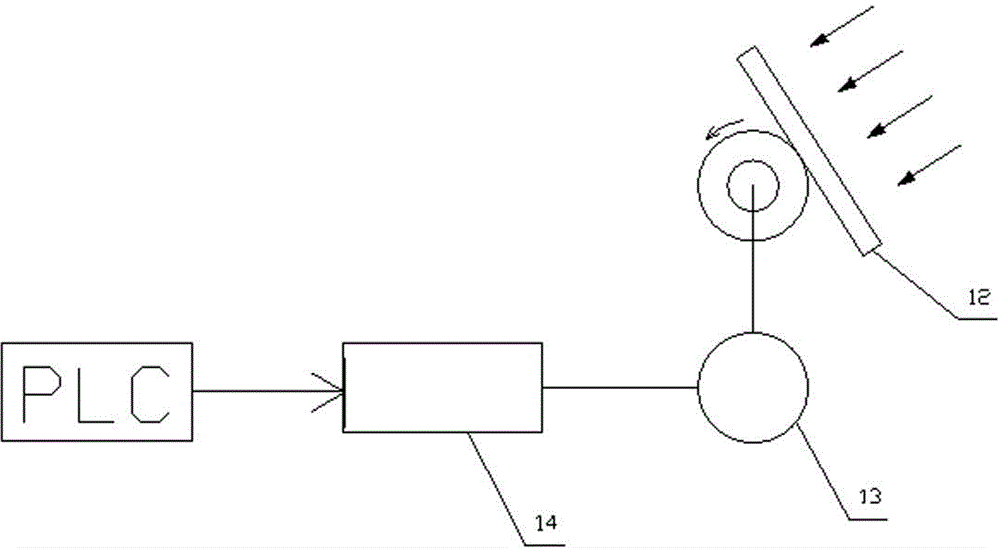

[0031] Please refer to figure 1 , the phot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com