Method for preparing an electrode pattern of conductive silicone rubber, electrostatic chuck composed entirely of silicone rubber, and method for manufacturing the same

A technology for electrode patterns and manufacturing methods, which is applied in the field of processing conductive silicone rubber sheets into electrode pattern shapes, and can solve problems such as large elongation and difficulty in processing electrode patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

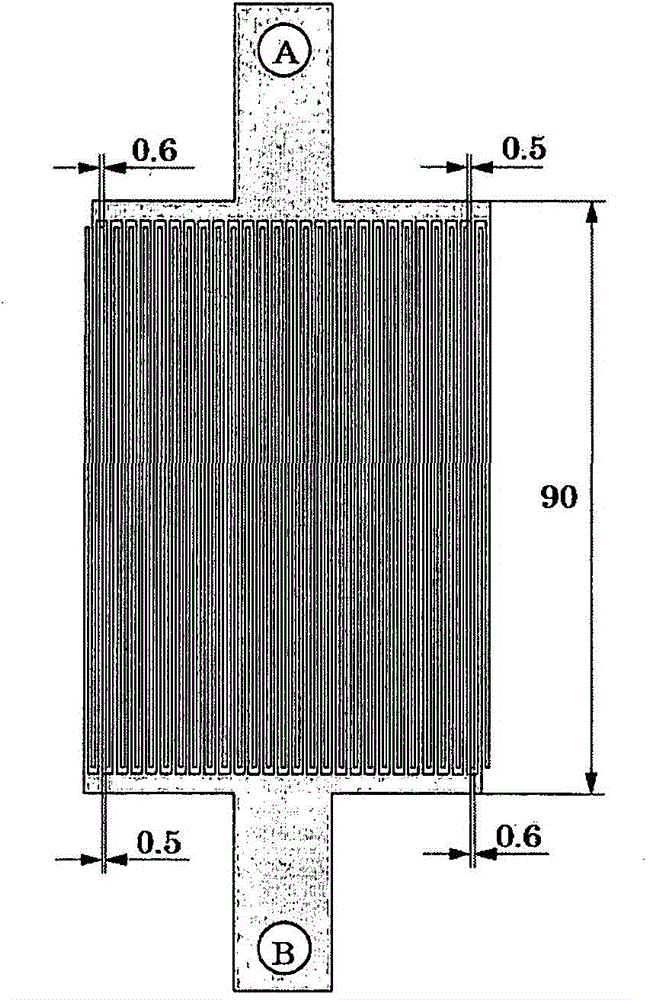

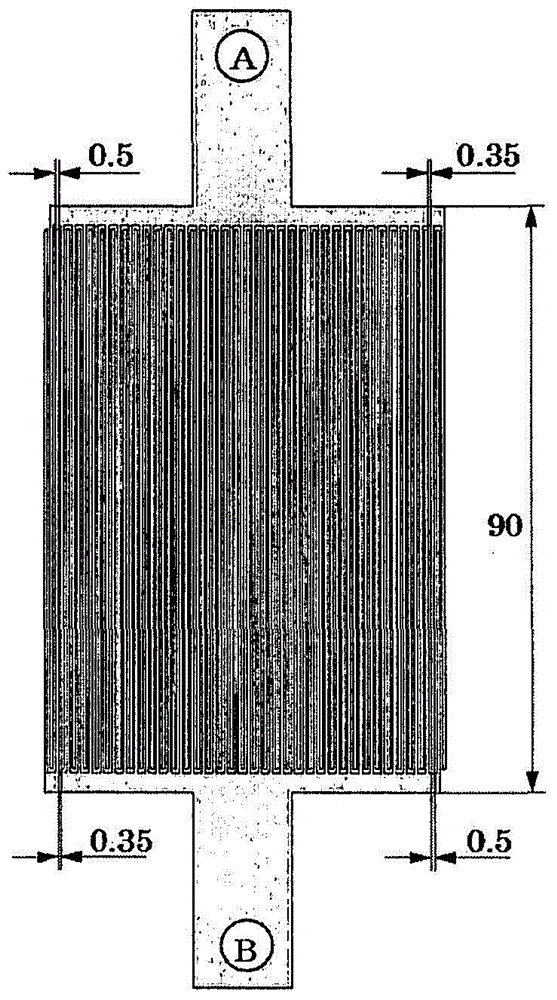

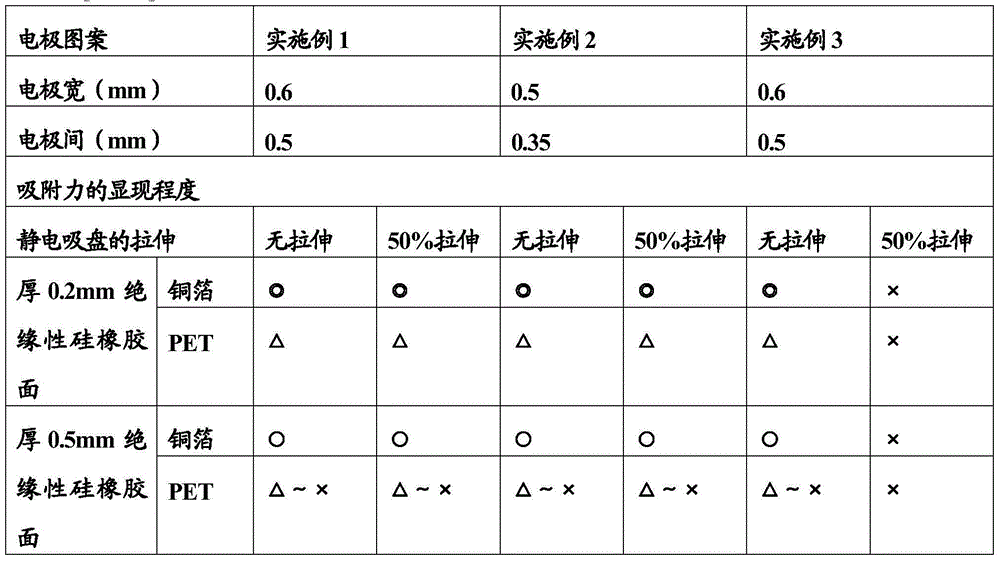

Embodiment 1、2

[0099] Made of methylvinyl polysiloxane with an average degree of polymerization of 8,000, composed of 99.6 mol% of dimethylsiloxane units and 0.4 mol% of methylvinylsiloxane units, and capped with trimethylsiloxy groups at both ends. To 100 parts by mass of oxane, 60 parts by mass of acetylene black as carbon black was blended with a pressurized kneader, kneaded to make it uniform, and prepared a kneaded rubber. With respect to 100 parts by mass of the rubber compound, 0.1 parts by mass of vinylsiloxane complex of chloroplatinic acid (platinum content 1 mass %), 0.05 parts by mass of ethynylcyclohexanol as a platinum catalyst control agent and The following formula (2)

[0100] (CH 3 ) 3 SiO[(CH 3 ) 2 SiO] 18[(CH 3 )HSiO] 20 Si(CH 3 ) 3

[0101] (2)

[0102] 2 parts by mass of the methylhydrogenpolysiloxane shown was fully kneaded with twin rolls to prepare an uncured conductive silicone rubber composition.

[0103] The conductive silicone rubber composition was s...

Embodiment 3

[0110] In 100 parts by mass of A and B of the liquid insulating silicone rubber material KE-1934A / B [trade name, manufactured by Shin-Etsu Chemical Co., Ltd.] compounded with a silicone resinous copolymer at a ratio of 1:1 250 parts by mass of silver glass beads S-5000-S3 [trade name, manufactured by Portables Barotini Co., Ltd.], which coated glass beads with silver as a conductive filler, were added and mixed to prepare a liquid uncured conductive silicone rubber. combination.

[0111] After defoaming the conductive silicone rubber composition, a predetermined amount was discharged on the blasted surface of a process film made of polyethylene terephthalate with a thickness of 100 μm. A stainless steel frame with a thickness of 0.2 mm was installed, and the glossy side of a polyethylene terephthalate film with a thickness of 100 μm was placed from above, and the upper and lower sides were sandwiched between two stainless steel plates with a thickness of 3 mm. Using a 50-ton ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com