Electric automobile battery pack heat management system and working method thereof

A thermal management system and technology for electric vehicles, applied in the field of electric vehicle battery thermal management, can solve the problems of long circulation pipelines, reduced system work efficiency, and no insulation measures are taken.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

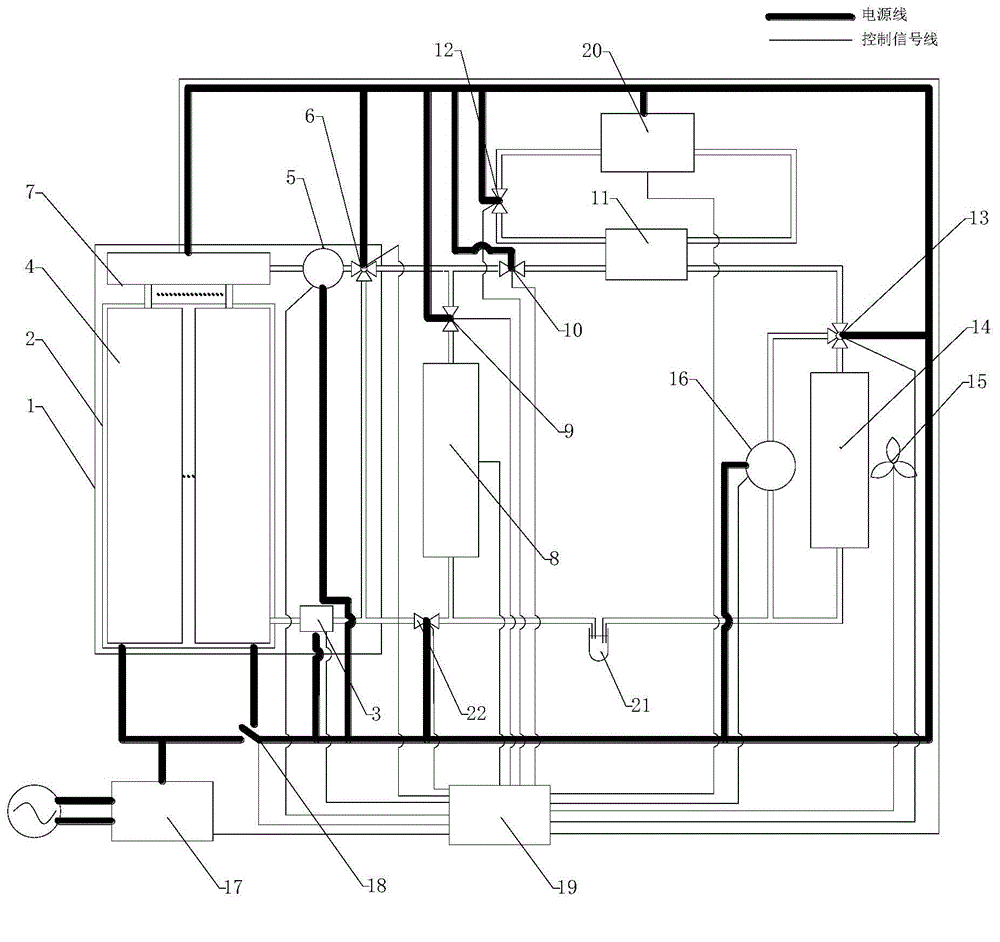

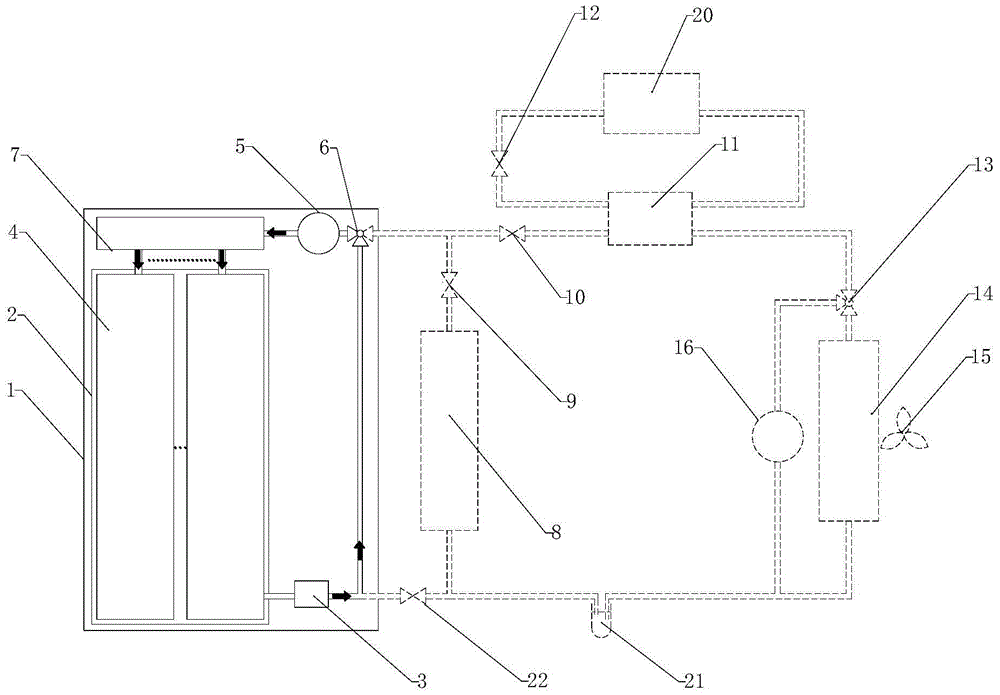

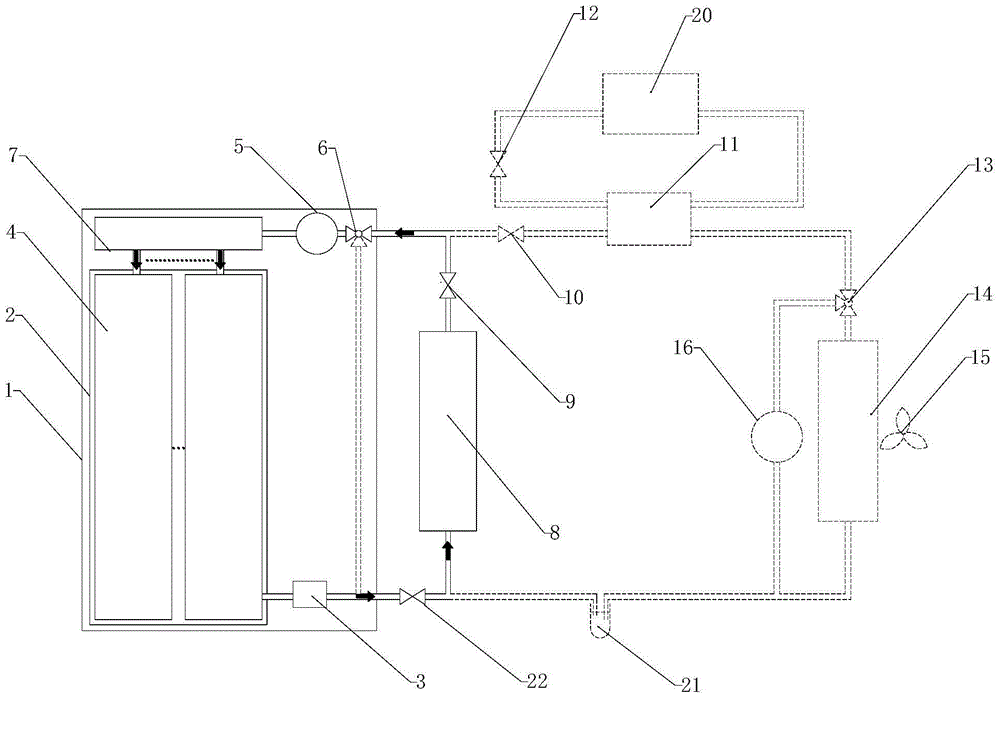

[0043] The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0044] A thermal management system for an electric vehicle battery pack, as attached figure 1 As shown, the whole system is mainly composed of the following parts, including:

[0045] The battery box 1, the inner wall of the battery box 1 is coated with heat insulating material, so that the battery box 1 has a thermal insulation effect;

[0046] The battery pack 2 is installed in the battery box 1, the battery pack 2 is composed of at least two battery modules A and B, and each battery module includes at least two battery cells;

[0047] The liquid circulation path inside the battery box 1 mainly includes:

[0048] The heating unit A3 is connected to the heat exchanger A4, and the heating unit A3 adopts an electric heating method, such as resistance wire, electric heating film, etc.;

[0049] The heat exchanger A4 is in close contact with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com