Vehicle-mounted charging machine capable of adjusting dead time based on phase-shift full-bridge circuit

A vehicle-mounted charger and phase-shifting full-bridge technology, which is applied in electric vehicles, circuit devices, battery circuit devices, etc., can solve problems such as the difficulty of implementing the lagging arm, and achieve the effects of accurate dead time, precise adjustment, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

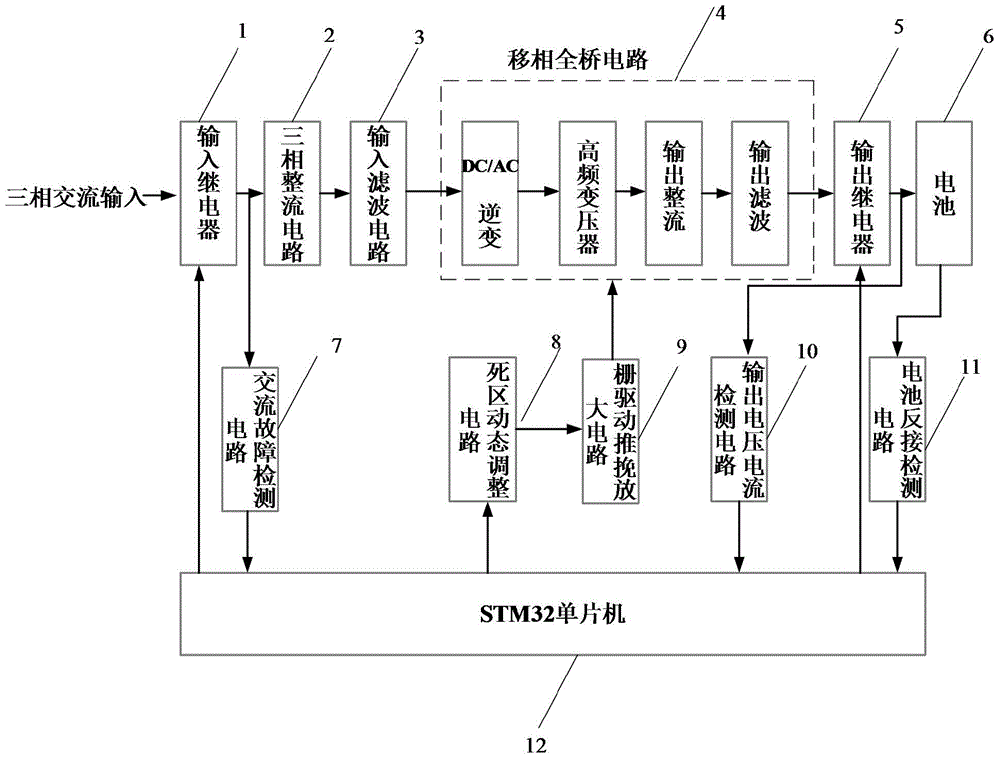

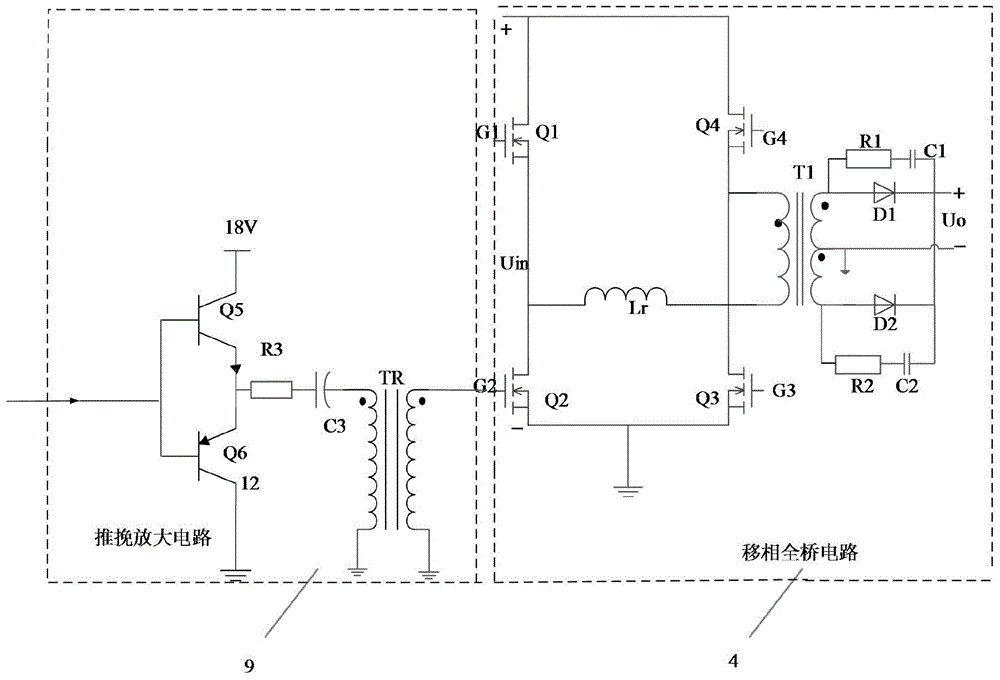

[0026] Such as figure 1, the three-phase AC input is sequentially connected to the input relay 1, the three-phase rectifier circuit 2, the input filter circuit 3, the phase-shifted full-bridge circuit 4 (including DC / AC inverter, high-frequency transformer, output rectifier and output filter), output Relay 5, battery 6, output voltage and current detection circuit 10 are connected between the output terminal of output relay 5 and STM32 single-chip microcomputer 12 (if output relay is not provided, then be connected between phase-shifting full-bridge circuit 4 and STM32 single-chip microcomputer 12), STM32 The single-chip microcomputer 12 outputs four channels of PWM signals and is connected to the dead zone dynamic adjustment circuit 8, and the dead zone dynamic adjustment circuit 8 outputs four channels of four PWM signals with dead zone times, respectively connected to four gate drive push-pull amplifier circuits 9 with the same structure The input terminals of the four grid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com