Rotating kinetic-energy perpetual-motion generator

A generator and kinetic energy technology, applied to electrical components, electromechanical devices, etc., can solve problems such as low energy conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

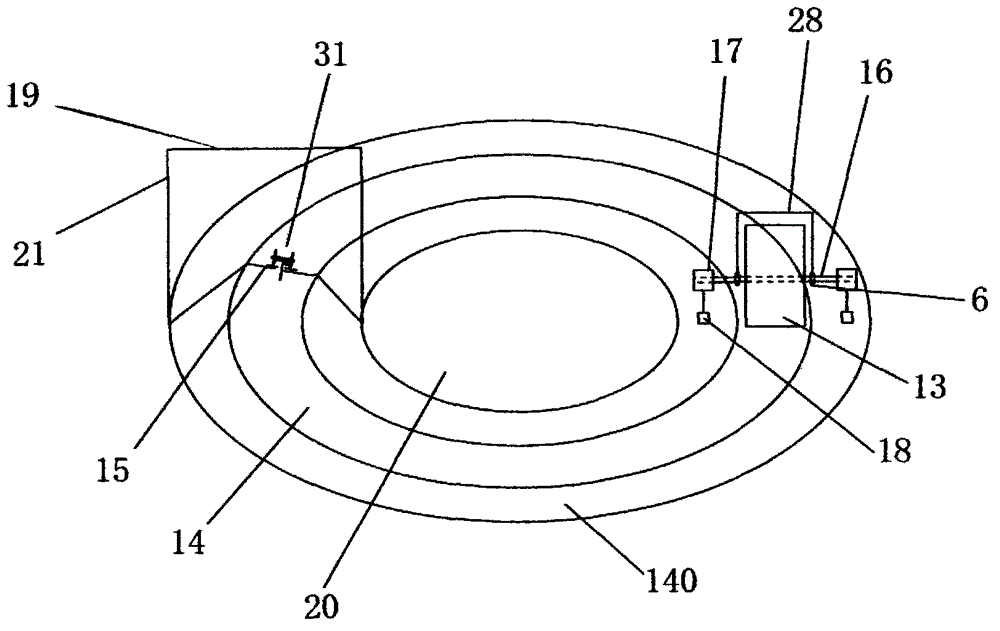

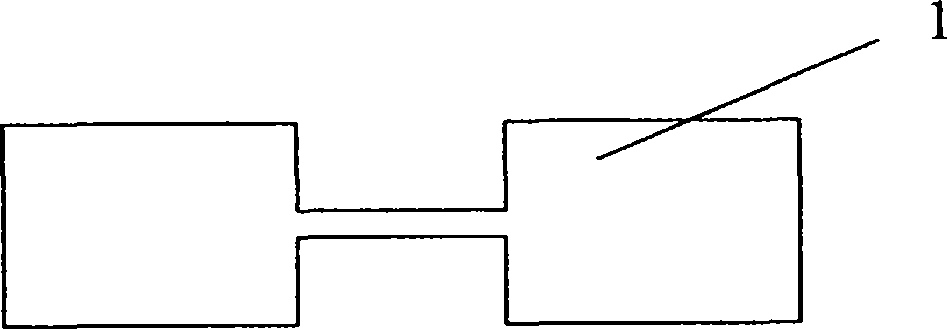

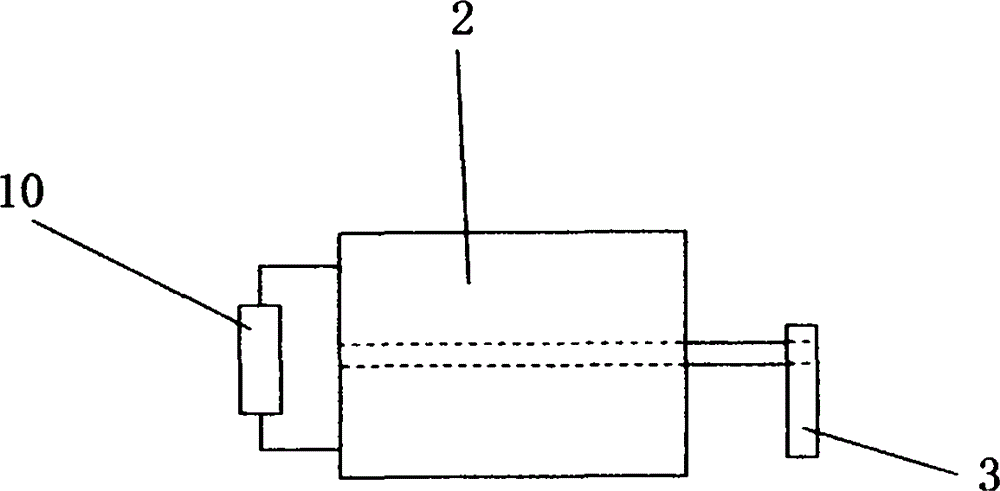

[0099] Embodiment of large rotational kinetic energy perpetual motion generator:

[0100] Such as Figure 2 to Figure 5 The principles shown in Experimental Examples 1 to 5, such as figure 1 , Image 6 , Figure 7 A kind of rotational kinetic energy perpetual motion generator shown is divided into super large, large and small three kinds of rotational kinetic energy perpetual motion generators, such as figure 1 The shown large-scale rotating kinetic energy perpetual generator mainly includes electric traction pull car 31, cylindrical steel column 13, cylindrical steel column fixed shaft 16, generator 17 with the steel column center fixed shaft as the rotating shaft, rolling bearing 6, two The side is provided with components such as the cylinder steel column rolling runway 14 of anti-jump wall 27 and ditch 140. The feature of the large rotational kinetic energy perpetual generator is:

[0101] On a relatively smooth horizontal ring belt with an outer diameter of 1148 me...

Embodiment 2

[0103] Embodiment of the extra-large rotational kinetic energy perpetual generator:

[0104] Such as Image 6 The super large rotary kinetic energy perpetual generator shown in the figure, a single set of super large rotary kinetic energy perpetual generator mainly includes a first-stage cylindrical steel column 131, a central fixed shaft 160 of the first-stage cylindrical steel column, two sets of large rotary Kinetic energy perpetual motion generator equipment and two sides are provided with 0.5M high anti-jump wall 27 and generator 17 shell hanging heavy objects running ditch 140 cylindrical steel column rolling ground runway 14. Between the two ground runways 14, there is a circular runway 141 of a first-level cylindrical steel column, and the runway 141 is set on the raised base 24 of the circular runway of the first-level cylindrical steel column. , the height of the raised base 24 is greater than the diameter of the cylindrical steel column 13 on which the generator is...

Embodiment 3

[0106] Embodiment of small-sized rotational kinetic energy perpetual motion generator:

[0107] Such as Figure 7The small rotary kinetic energy perpetual generator shown in the figure, a single set of small rotary kinetic energy perpetual generator mainly includes a first-stage cylindrical steel column 131, a central fixed shaft 160 of the first-stage cylindrical steel column, a spring 22, and a pulling pulley track 23 for the generator casing , generator housing pull pulley 25, generator housing tension spring running groove 26, traction lever 30, fulcrum hole 33, fulcrum column 34, fulcrum stigma 35, eccentric wheel 36, eccentric wheel drive motor 37, a set and super large rotational kinetic energy A single group of extra-large rotational kinetic energy perpetual generators with the same structure as described in the perpetual generator embodiment, etc. It is characterized in that two ground runways 14 and the raised first-class cylindrical steel column runway 141 of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com