Method for realizing two colors and two kinds of luster, plastic casing and terminal

A plastic shell, glossy technology, applied in the parts of cabinets/cases/drawer drawers, crafts for producing decorative surface effects, decorative arts, etc. And the problem of single color, etc., to achieve the effect of sharp contrast and better texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

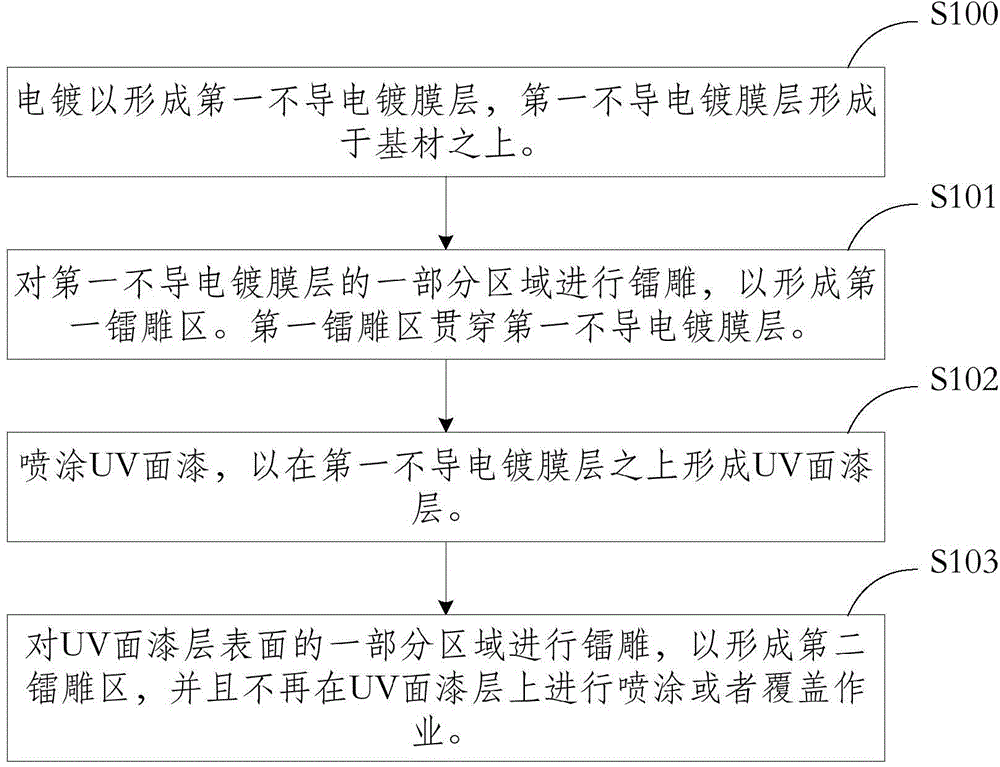

[0039] see figure 1 , is a schematic flowchart of the first embodiment of the method for realizing two-color and double-gloss of the present invention.

[0040] In this embodiment, the method for realizing two-color and two-gloss comprises the following steps:

[0041] S100, electroplating to form a first non-conductive coating layer, the first non-conductive coating layer is formed on the substrate.

[0042] In this embodiment, it can be carried out by water plating or NCVM process. This embodiment adopts NCVM process. NCVM process can make a metal appearance effect and play a role in beautifying the surface of the workpiece, and the first non-conductive coating formed by it The thickness of the layer is less than 0.3 μm, such as 0.1 μm or 0.2 μm. The first non-conductive coating layer has no conductivity. When the digital product receives signals or transmits signals, the electromagnetic field generated is not stored by the coating layer, thus not affecting The radio frequ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com