Fuel injection system for use in a catalytic heater and reactor for operating catalytic combustion of liquid fuels

一种燃料喷射系统、催化燃烧器的技术,应用在系统领域

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] For the purposes of this application, the following terms shall have the indicated meanings.

[0018] "Multicomponent fuels" are commercially available fuels such as diesel and gasoline, which are mixtures of different hydrocarbons having different boiling points, carbon chain lengths and structures.

[0019] The use of these commonly available commodity fuels has been limited to catalytic combustion systems due to: the complete vaporization of the heavier components of the fuel without the generation of coke from the lighter components of the fuel by pyrolysis and the absence of low temperatures The generation of soot during catalyst light-off is very complex.

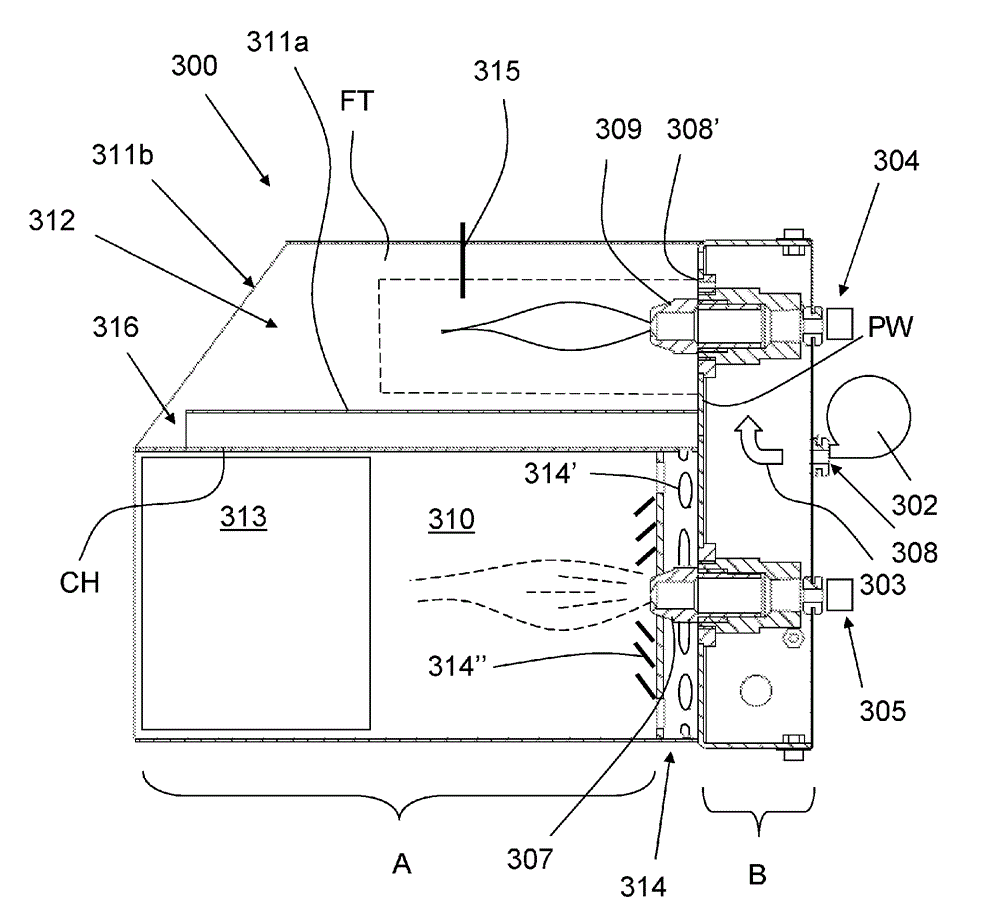

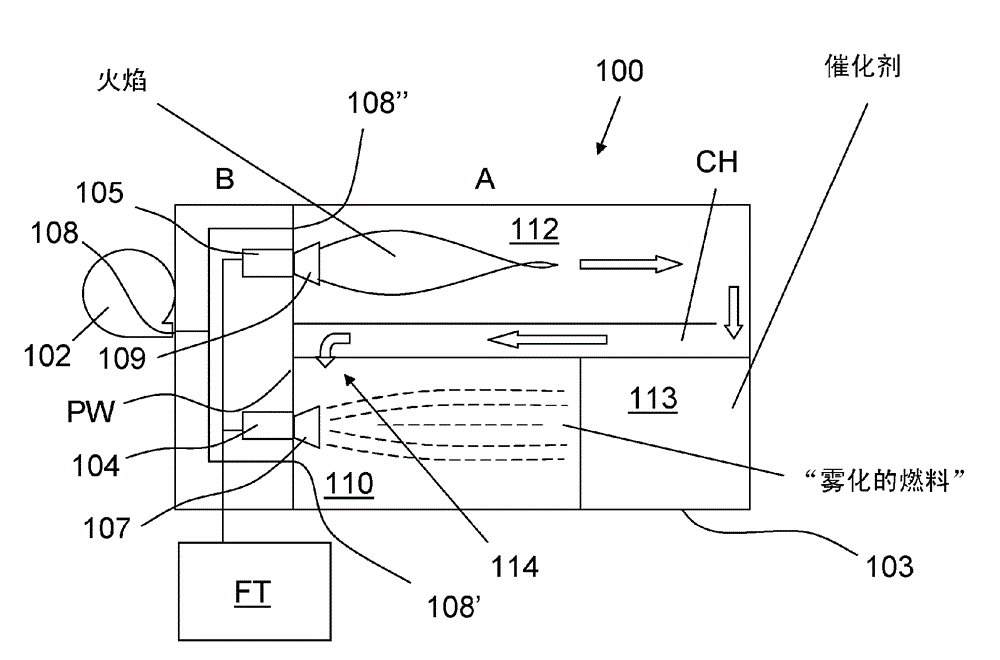

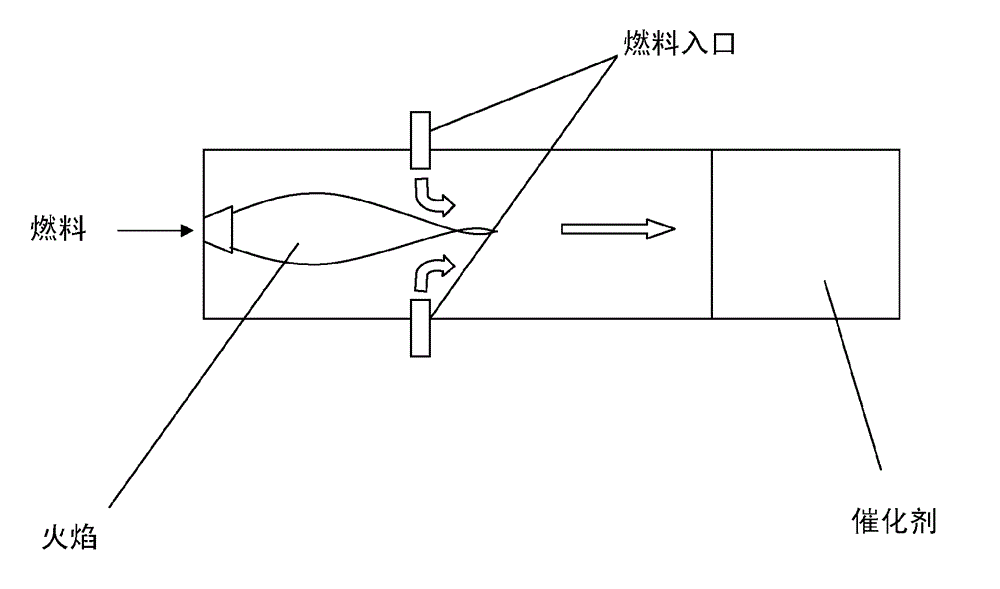

[0020] Referring to the drawings, in Figure 1 a prior art system according to US-6,223,537 is disclosed. The system includes a combustion chamber 10 having a generally double-walled pot-shaped configuration. The combustor 10 includes a combustor can 11 , a liner 12 and an upstream end 14 . The combustor can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com