Rubber hose and preparation method thereof

A rubber hose, nitrile rubber technology, applied in the direction of hoses, pipes, adhesives, etc., can solve the problems of high-pressure hose fire resistance that cannot be mixed, the reaction of compound flame retardants cannot be controlled, and applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] Inner lining layer; the preparation raw material of described inner lining layer comprises nitrile rubber and NBR / PVC rubber-plastic alloy;

[0040] The first steel wire skeleton layer compounded on the inner lining layer;

[0041] The middle rubber adhesive layer compounded on the steel wire skeleton layer; the preparation raw materials of the middle rubber adhesive layer include nitrile rubber and neoprene rubber;

[0042] The second steel wire skeleton layer compounded on the middle glue bonding layer;

[0043] The outer rubber layer compounded on the second steel wire skeleton layer; the preparation raw materials of the outer rubber layer include nitrile rubber, rubber-plastic alloy and compound flame retardant;

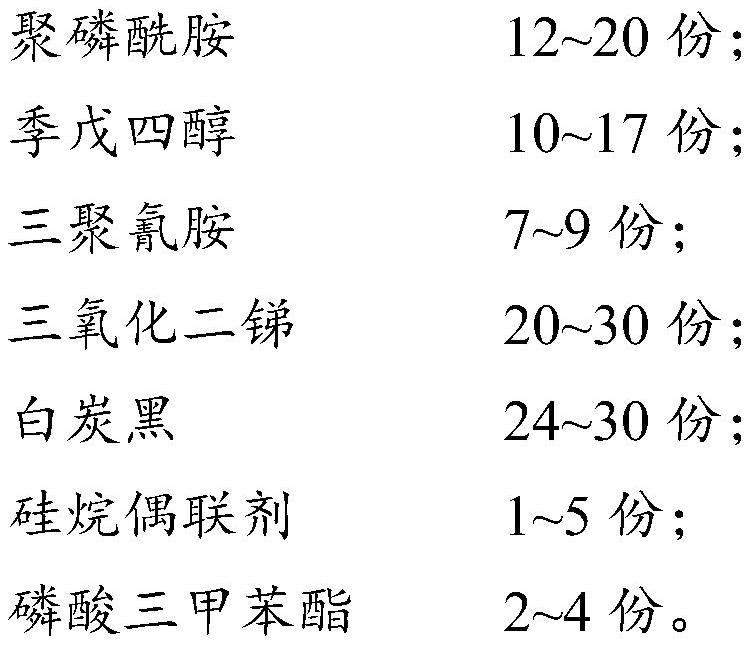

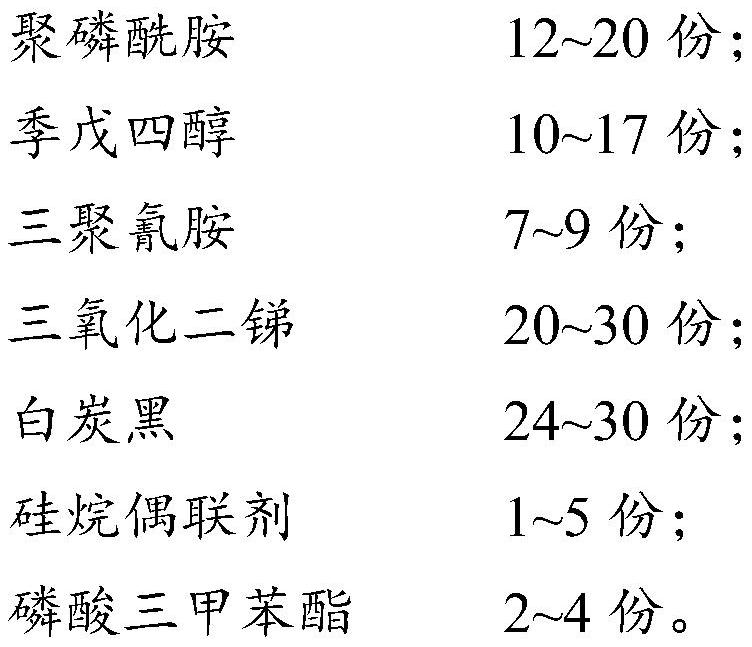

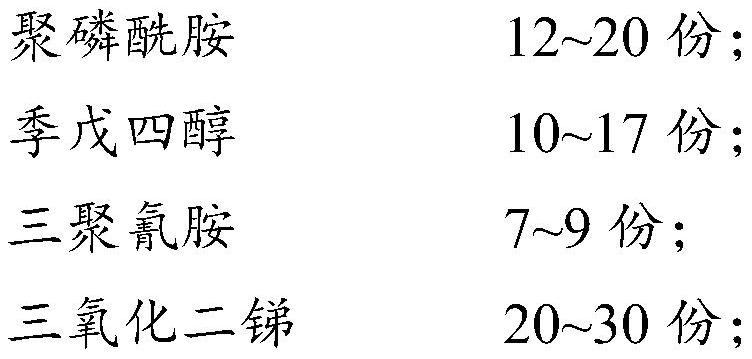

[0044] Described composite flame retardant comprises by weight parts:

[0045]

[0046]

[0047] The rubber hose provided by the invention includes an inner liner, and the preparation raw materials of the inner liner include nitrile rubber and NBR / ...

Embodiment 1~17 and comparative example 1~10

[0237] The inner liner is prepared from raw materials comprising the following parts by weight:

[0238] China Taiwan LANXESS nitrile rubber 3370C 75 parts, Hangzhou Keli chlorinated polyethylene rubber CH100 10 parts, Hebei Jiansheng NBR / PVC rubber-plastic alloy 25 parts, Shanghai Cabot fine particle furnace black 45 parts, Shanghai Cabot 45 parts of soft furnace black, 2 parts of anti-aging agent N-isopropyl-N'-phenyl-p-phenylenediamine, 1.5 parts of anti-aging agent trimethyl-1,2-dihydroquinoline, 2 parts of calcium zinc stabilizer , 4 parts of zinc oxide, 1 part of stearic acid, 5 parts of magnesium oxide, 10 parts of white carbon black, 7 parts of dioctyl phthalate, 2 parts of sulfur, accelerator 2-(4-morpholinethio)benzene 0.5 part of thiazole, 1.4 part of accelerator dithiodimorpholine, 0.3 part of anti-scorch agent N-cyclohexylthiophthalimide, 0.5 part of dicumyl peroxide;

[0239] The preparation method of lining pipe compound comprises the following steps:

[0240]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com