Flexible metal sheet shearing center

A sheet metal shearing and flexible metal technology, applied in the direction of shearing devices, metal processing equipment, shearing machine equipment, etc., can solve the problems of inaccurate positioning of sheets, small clamping force, and accumulation on sheets, etc., and achieve labor Effects of low strength, high productivity, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

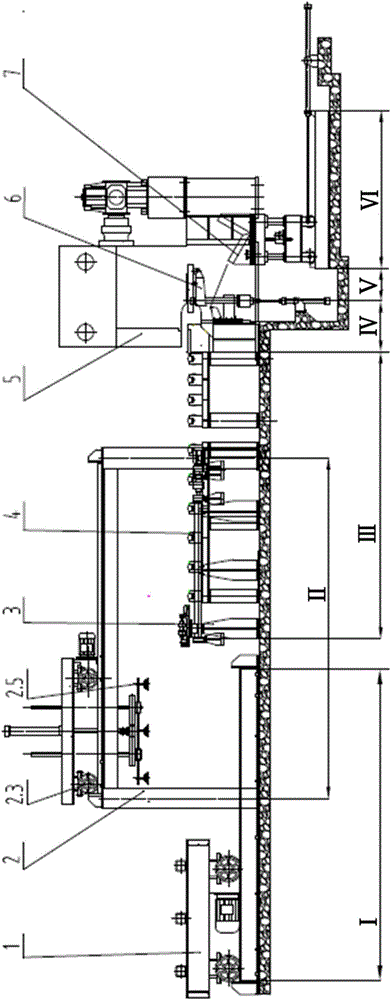

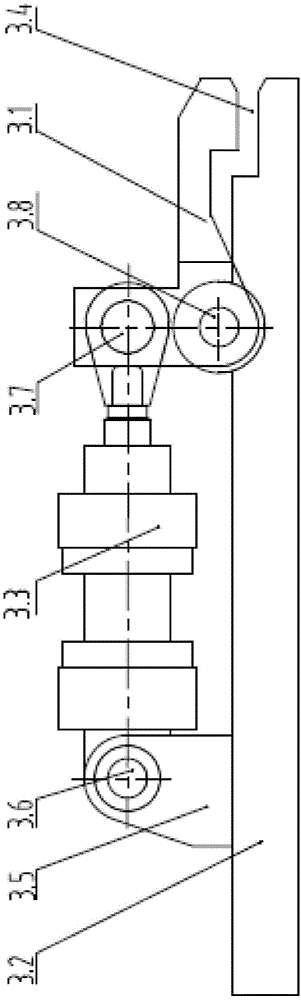

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in detail: as figure 1 As shown, track section I and roller section III are installed in sequence at the front end of shear section IV on the shear center production line, and discharge section V and collection area are installed sequentially behind shear section IV Section VI.

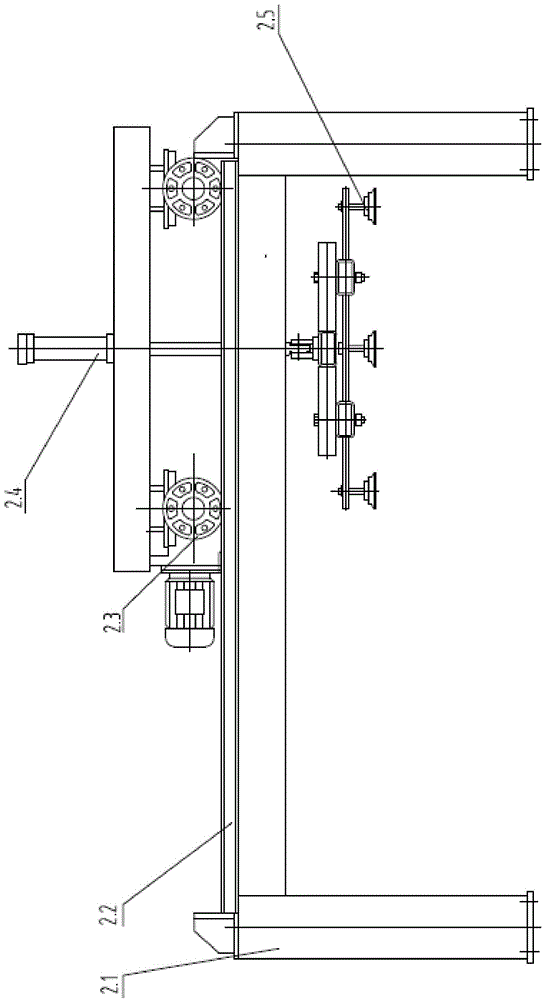

[0023] When the sheet material to be cut is placed on the incoming material trolley 1, the incoming material trolley 1 is driven to send the sheet material forward to the gantry crane section II. When the sensor installed on the gantry crane 2 detects the incoming material, the crane is operated. The extension of the piston rod of the lifting hydraulic cylinder 2.4 drives the vacuum suction cup 2.5 at the lower end to go down, so as to absorb the sheet material and then move upward with the contraction of the piston rod of the lifting hydraulic cylinder 2.4, and move forward with the advanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com