A kind of environmental protection lightweight soundproof pad and production method thereof

A lightweight, sound-insulating pad technology, applied in the field of auto parts manufacturing, can solve the problem of unfriendly passenger compartment odor, and achieve the effect of weight reduction, low VOC emission, and easy combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

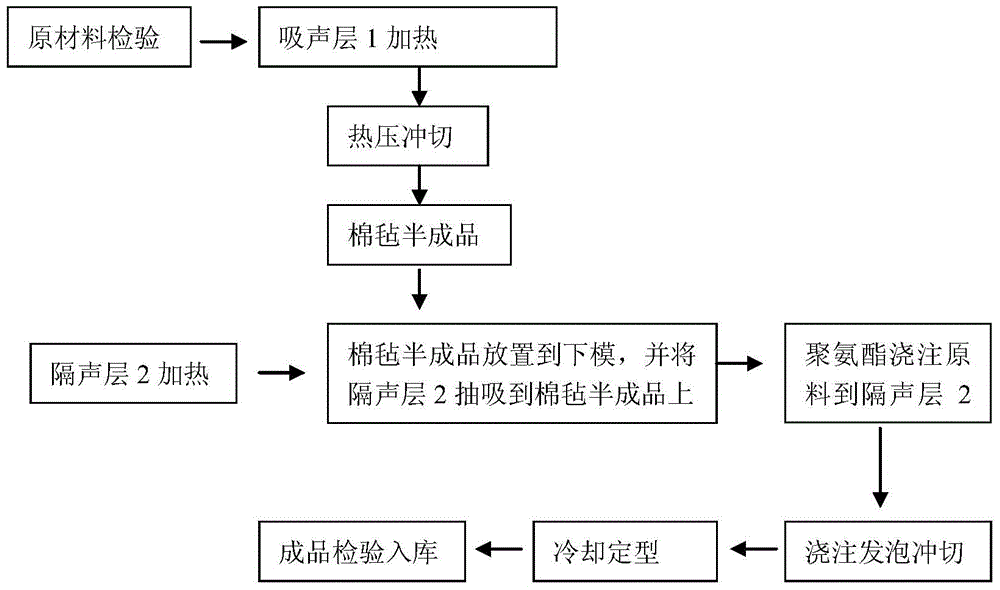

[0031] An environmentally friendly lightweight sound insulation pad will be realized through the following process.

[0032] Step 1. Preparation of raw materials: According to the consumption quota requirements of the product, the sound insulation layer 2 is cut into raw material sheets of predetermined size. The sound insulation layer breaks the polymer chains on the surface through arc discharge, thereby increasing the surface tension, improving the adhesion with PU foam, and preventing delamination. The discharge current is 1.5A, and the surface tension reaches 36 dynes.

[0033] Step 2. The sound-absorbing layer 1 is sent into the hot blast stove by the automatic feeding mechanism for heating. Hot air temperature: 210°C, the wind speed of hot air injection is 6m / s. The distance between the air outlet and the heating surface: 10mm, and the heating time is 15s.

[0034]Step 3. The heated sound-absorbing layer 1 is transferred to a hot-press punching die for pressing and f...

Embodiment 2

[0046] An environmentally friendly lightweight sound insulation pad will be realized through the following process.

[0047] Step 1. Preparation of raw materials: According to the consumption quota requirements of the product, the sound insulation layer 2 is cut into raw material sheets of predetermined size. The sound insulation layer breaks the polymer chains on the surface through arc discharge, thereby increasing the surface tension, improving the adhesion with PU foam, and preventing delamination. The discharge current is 2.5A, and the surface tension reaches 38 dynes.

[0048] Step 2. The sound-absorbing layer 1 is sent into the hot blast stove by the automatic feeding mechanism for heating. Hot air temperature: 240°C, hot air jet speed is 15m / s. The distance between the air outlet and the heating surface: 20mm, and the heating time is 20s.

[0049] Step 3. The heated sound-absorbing layer 1 is transferred to a hot-press punching die for pressing and forming, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com