Efficient anaerobic reactor resistant to high-concentration sulphate and method for treating wastewater using efficient anaerobic reactor

An anaerobic reactor and sulfate technology, applied in anaerobic digestion treatment, chemical instruments and methods, separation methods, etc., can solve the problems of strong inhibition, low anaerobic system treatment efficiency, poor operability, etc., and achieve relief Toxic action, effective resistance to poisoning action, high treatment load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

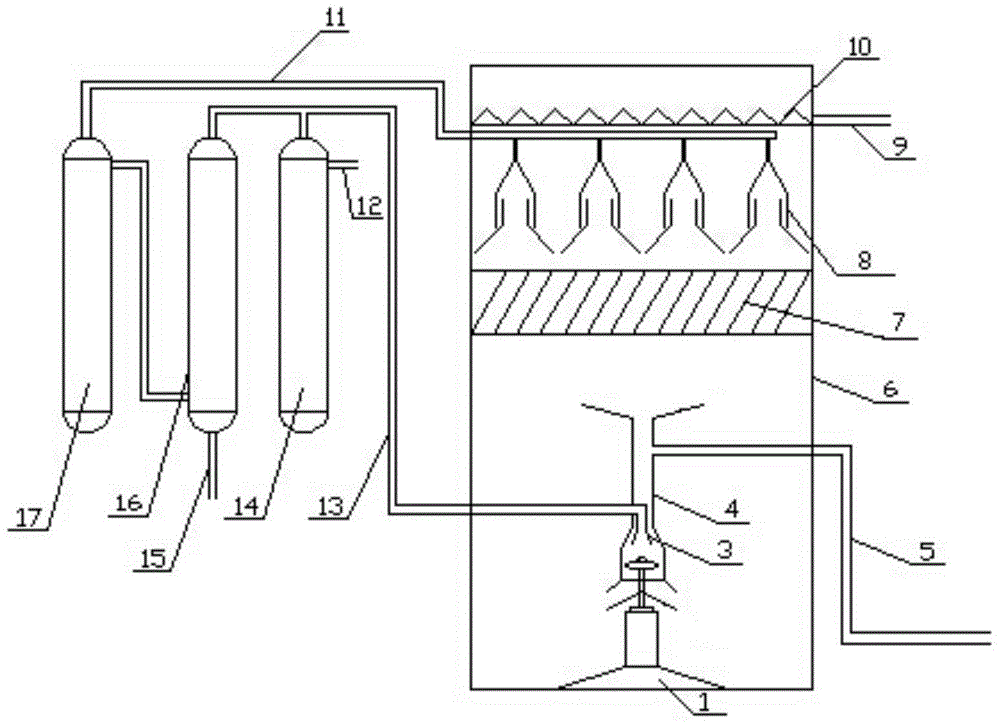

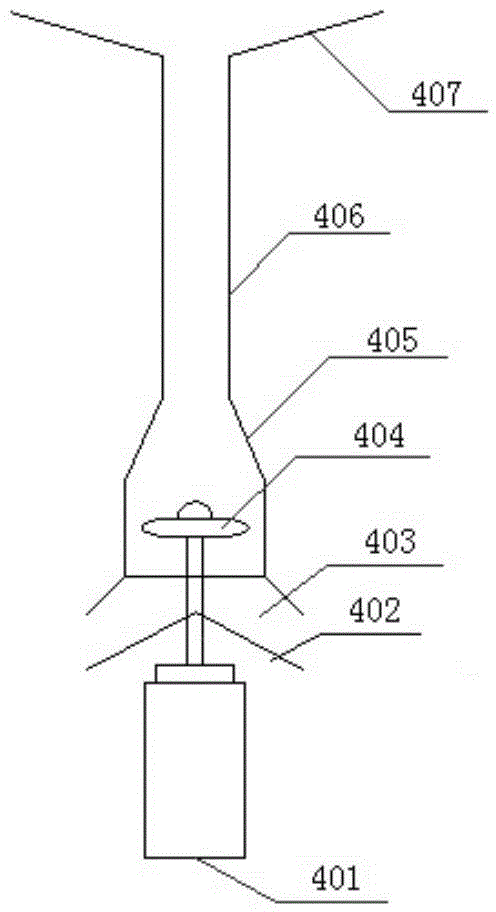

[0041] Such as figure 1 and figure 2 As shown, a high-efficiency anaerobic reactor resistant to high-concentration sulfate includes an internal circulation anaerobic reactor 6, and also includes an air guide pipe 11, a return air pipe 13, a gas collection tank 14, a complex iron oxidation tower 16 and a water seal Tank 17; internal circulation anaerobic reactor 6 includes fixed platform 1, internal circulation jet device 4, water inlet pipe 5, two-phase separator 7, three-phase separator 8, water outlet pipe 9 and outlet weir 10; internal circulation jet device 4 The bottom of the internal circulation anaerobic reactor 6 is fixed by the fixed table 1, wherein the internal circulation jet 4 includes a motor 401, a jet port 403, a high-speed paddle 404, a diffusion port 405, a draft tube 406 and a steady flow port 407, and the motor 401 and high-speed paddle 404 are connected by a rotating shaft, and a jet baffle 402 is also arranged on the rotating shaft. The jet baffle 402, ...

Embodiment 2

[0050] A high-efficiency anaerobic reactor resistant to high-concentration sulfate, the basic structure is the same as that of Example 1, the difference is that the height of the air distribution port 3 from the high-speed paddle 404 is 30 cm, and the funnel taper angle is 75 °. The diameter of the cone bottom is 3 / 4 of the diameter of the draft tube 406 .

[0051] The wastewater quality of a monosodium glutamate production enterprise in Henan Province after pretreatment is pH: 6-8; CODcr: 25000mg / L; SO 4 2- : 7000mg / L. Belong to high-concentration sulfate organic waste water, process according to the waste water treatment method described in the embodiment 1, waste water is treated with 100m 3 / d The water volume is continuously pumped into the high-concentration sulfate-resistant anaerobic reactor, and the internal circulation water volume is about 5 times to achieve full mixing and dilution, and the Fe in the complex iron oxidant 3+ The concentration is controlled at 0.2...

Embodiment 3

[0053]A high-efficiency anaerobic reactor resistant to high-concentration sulfate, the basic structure is the same as that of Example 1, except that the height of the air distribution port 3 from the high-speed paddle 404 is 25 cm, and the funnel taper angle is 60 °. The diameter of the cone bottom is 1 / 2 of the diameter of the draft tube 406 .

[0054] The wastewater quality of a certain mycin production enterprise in Jiangsu is pH: about 7; CODcr: 35000mg / L; SO 4 2- : 15000mg / L. Belong to high-concentration sulfate organic waste water, process according to the waste water treatment method described in the embodiment 1, waste water is treated with 50m 3 / d The water volume is continuously pumped into the high-concentration sulfate-resistant anaerobic reactor, and the internal circulation water volume is about 6 times to achieve full mixing and dilution, and the Fe in the complex iron oxidant 3+ The concentration is 0.6mol / L, the commissioning and start-up period is 10 week...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com