Aerobic composting reactor used for treating household garbage in cold area

A domestic waste and aerobic composting technology, applied in the direction of organic fertilizers, climate change adaptation, etc., can solve the problems of low conversion rate of domestic waste composting products, poor heating and heat preservation effects, insufficient ventilation and oxygen supply, etc., to achieve composting Good treatment effect, not easy to agglomerate, good heat preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

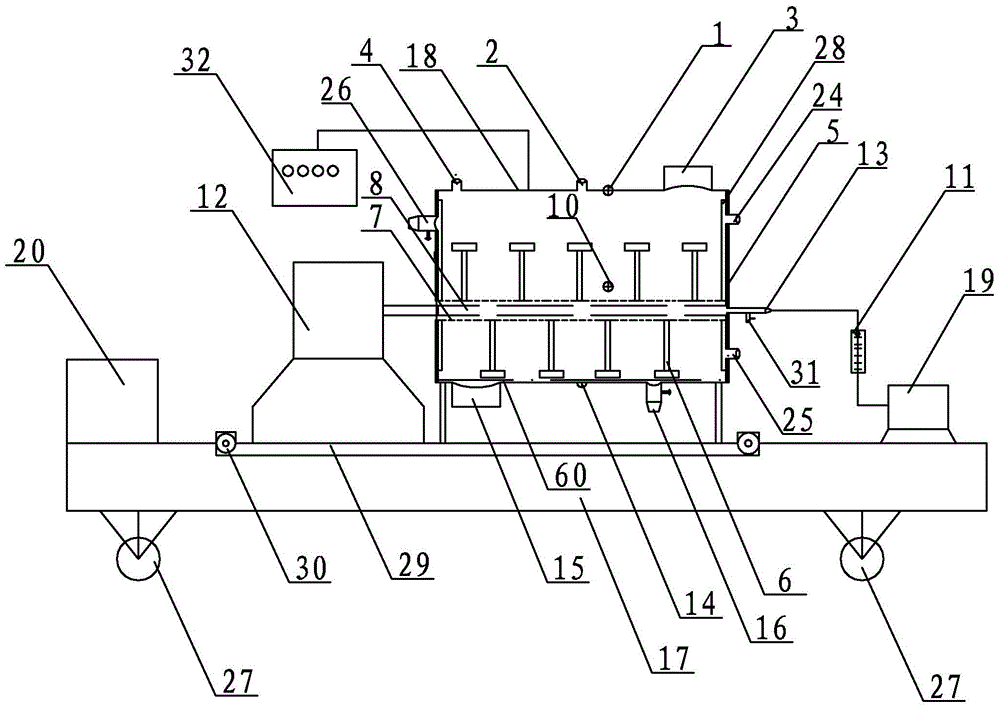

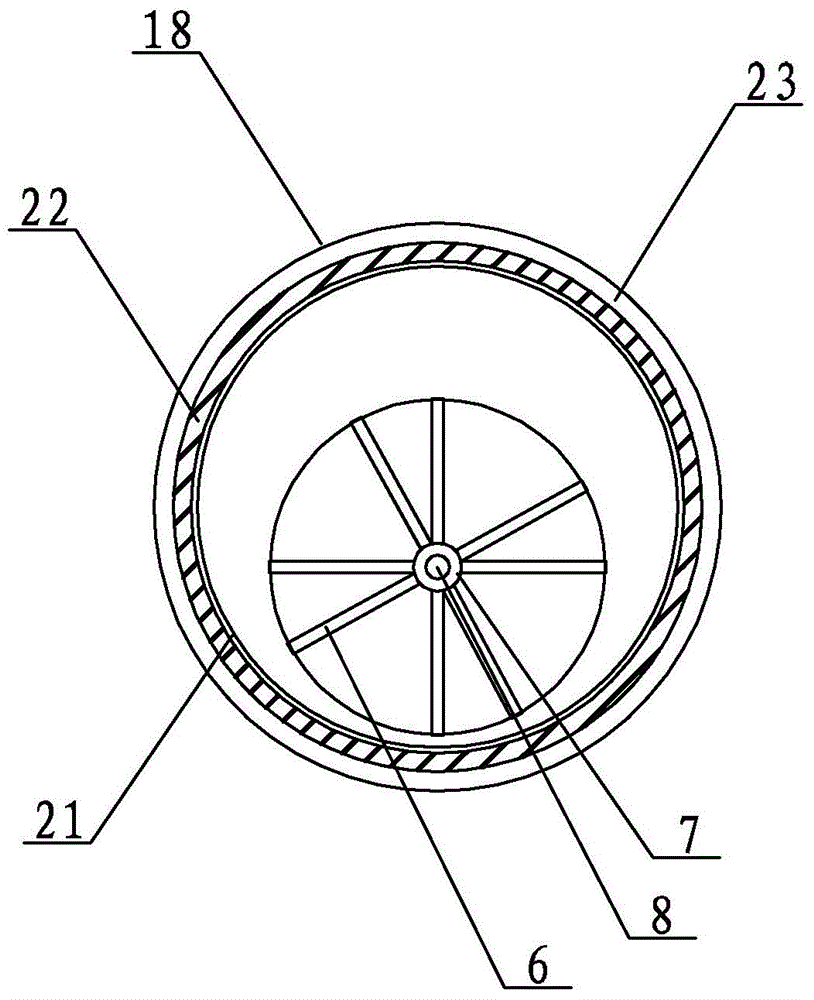

[0020] Specific implementation mode one: combine figure 1 with figure 2 Describe this embodiment, a kind of aerobic composting reactor that is used for processing household waste in severe cold area of this embodiment comprises frame body 17 and a plurality of rollers 27, and a plurality of rollers 27 are installed in the lower end of frame body 17, and described aerobic The composting reactor also includes a reactor temperature control box 20, a rotating bracket 29, an insulation layer 5, a motor 12, a gas flow meter 11, an air compressor 19, a columnar reactor tank body 18, a resistance wire temperature control box 32, and an inner shaft 8 , an outer shaft 7, a first temperature sensor 1, a second temperature sensor 10, a third temperature sensor 14, a plurality of stirring paddles 6 and two electrode plates 28,

[0021] The reactor temperature control box 20 is installed on one side of the frame body 17, the air compressor 19 is installed on the other side of the frame ...

specific Embodiment approach 2

[0031] Specific implementation mode two: combination figure 1 with figure 2 To illustrate this embodiment, the columnar reactor tank body 18 of this embodiment is further provided with a vertical leachate discharge port 26 and a vertical leachate return port 24 . So set, the effect of the vertical exhaust port 24 is: to exhaust when the reactor is vertical. The function of the vertical leachate outlet 26 is to flow out the leachate when the reactor is vertical. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0032] Specific implementation mode three: combination figure 1 with figure 2 The present embodiment will be described. The thermal insulation layer 5 of the present embodiment is a polyurethane thermal insulation layer. With such setting, the heat preservation effect is good. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

[0033] Specific implementation mode four: combination figure 1 with figure 2 Describe this embodiment, the diameter of the small hole opened on the inner shaft 8 and the outer shaft 7 of this embodiment is 3mm-8mm. When in use, the optimal diameter of the small hole is 5mm. Such a setting is convenient for air intake or water supply of the inner shaft. Other compositions and connections are the same as those in Embodiment 1, 2 or 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com