High-flatness water transfer film coating and preparation method thereof

A water transfer film coating, flatness technology, applied in the coating and other directions, can solve the problem of laser pattern wrinkle and other problems, and achieve the effect of improving the overall flatness and local wrinkling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

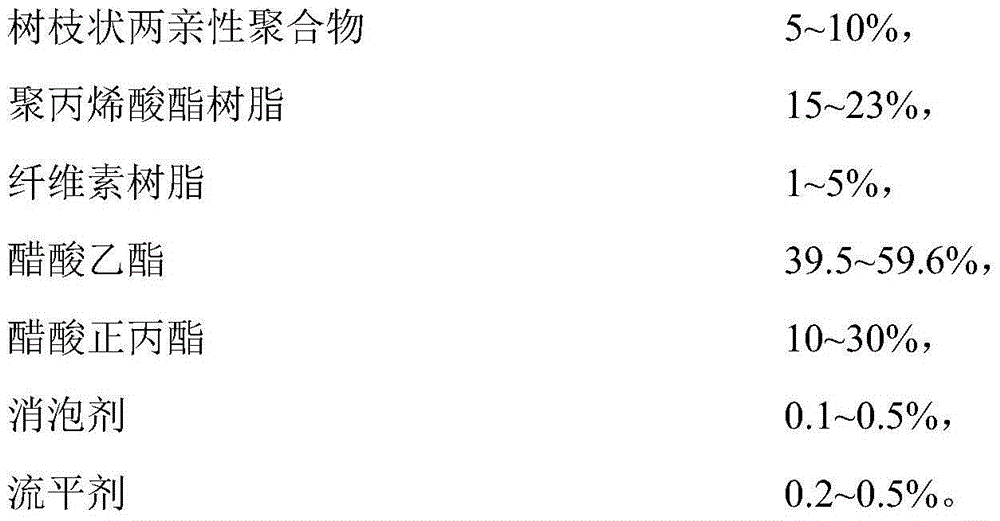

Embodiment 1

[0031] Embodiment 1 provides a high-level water transfer film coating and a preparation process thereof. The preparation method is specifically: according to the formula ingredients in Table 1, first fully mix the two solvents of ethyl acetate and n-propyl acetate, and stir After 10-30 minutes, add polyacrylic resin and cellulose resin into the reaction kettle, stir for 30 minutes to fully dissolve, then add dendritic polymer, stir for more than 1 hour, fully disperse and dissolve; finally add defoamer and leveling agent, Fully stirred, high flatness water transfer film coating.

Embodiment 2

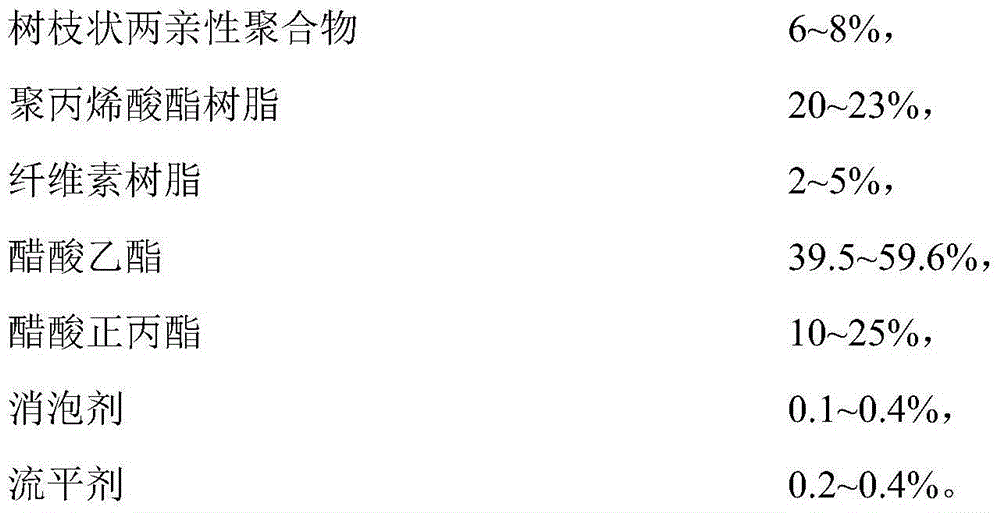

[0033] Its formula is shown in Table 1, and the preparation method is the same as in Example 1.

Embodiment 3

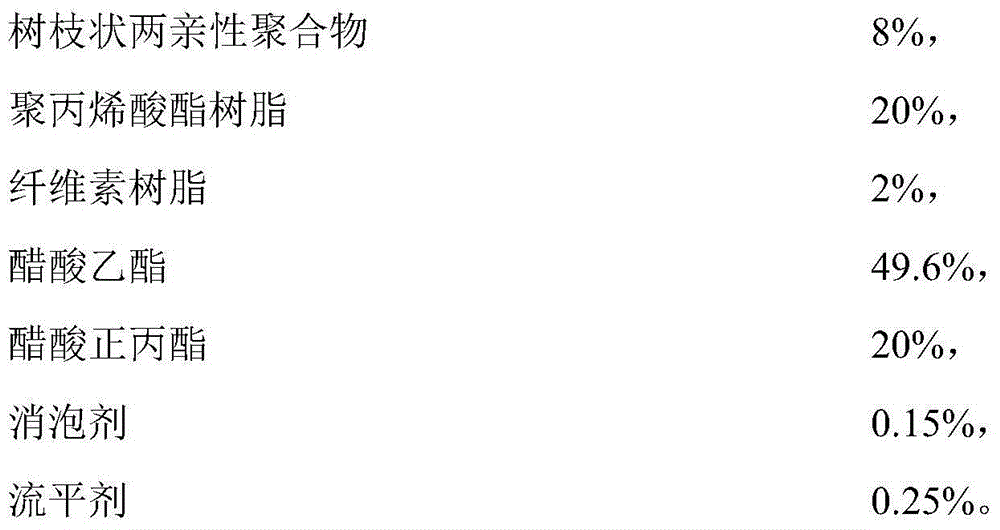

[0035] Its formula is shown in Table 1, and the preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com