Method for improving indium thermal conductive interface material

An interface material and material strip technology, which is applied in the field of improving the thermal conductivity of indium interface materials, can solve the problems of easy residual thermal stress and low thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

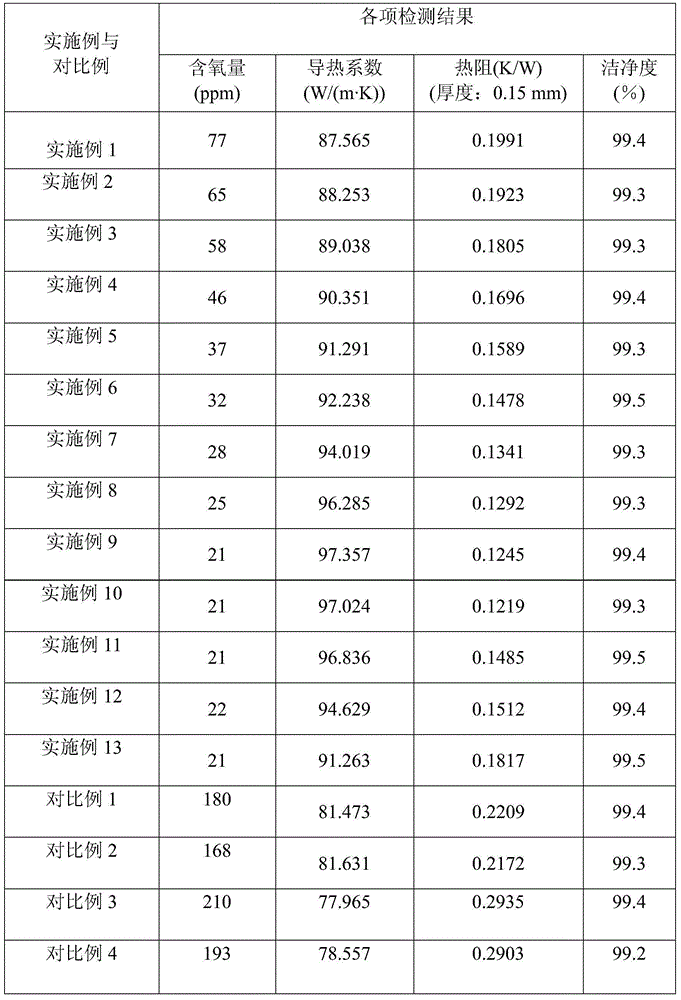

[0031] The following examples are further detailed descriptions of the present invention.

[0032] The method for improving the indium thermal interface material provided by the present invention is mainly reflected in adding 50-3000 ppm gallium to pure indium during the smelting process.

[0033] The technological process of this embodiment is:

[0034] 1. Special smelting process, put the pre-prepared pure indium in a vacuum induction melting furnace, first melt it at 280-320°C under non-vacuum conditions, and add 50-3000ppm gallium to the melted pure indium, stir 2 to 3 minutes and thoroughly remove the slag, then close the furnace cover, wait for the vacuum to be below 10Pa and keep it for half an hour, then cast into ingots under vacuum conditions, and remove the rough skin;

[0035] 2. Extrusion process, extruding the stripped ingot on the extruder to form a billet;

[0036] 3. Rolling process, rolling the strip blank on the rolling mill into a strip of required thickn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com