Low Back Pressure Rotary Compressors

A rotary compressor, low back pressure technology, applied in the field of compressors, can solve the problems of sliding vane and piston collision, motor tripping, compressor performance deterioration, etc., to achieve the effect of ensuring close sealing and good compressor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

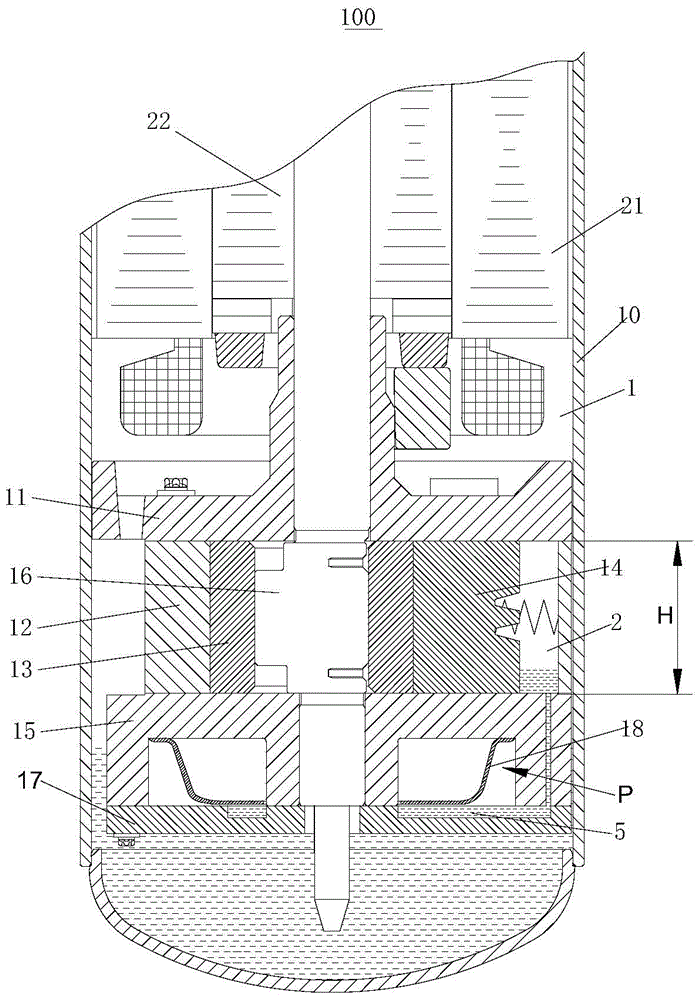

[0087] Such as figure 1 As shown, the low back pressure rotary compressor 100 according to the embodiment of the present invention includes: a casing 10, a motor and a compression mechanism. The housing 10 defines an inner space 1 communicating with the suction port. The motor is located on the top of the inner space 1. The motor is composed of a stator 21 and a rotor 22, wherein the rotor 22 is connected to the crankshaft 16 to drive the crankshaft 16 to rotate.

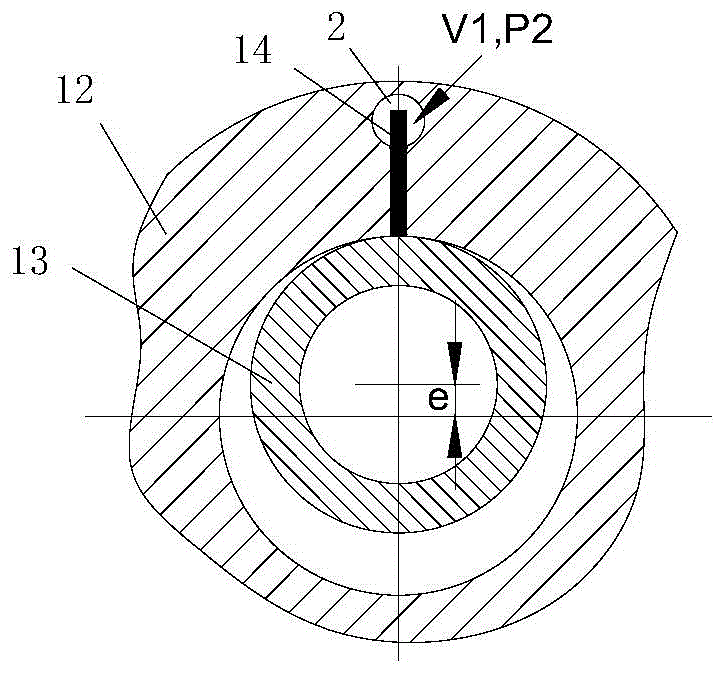

[0088] The compression mechanism includes: a cylinder 12 , a piston 13 and a sliding plate 14 arranged in the cylinder 12 , a crankshaft 16 for driving the piston 13 to rotate eccentrically, and a main bearing 11 and an auxiliary bearing 15 supporting the crankshaft 16 .

[0089] During the operation of the compressor, the sliding vane 14 reciprocates along the sliding vane groove 4 provided on the cylinder 12 , and the tip of the sliding vane 14 closely fits the outer diameter of the piston 13 to form a compression...

Embodiment 2

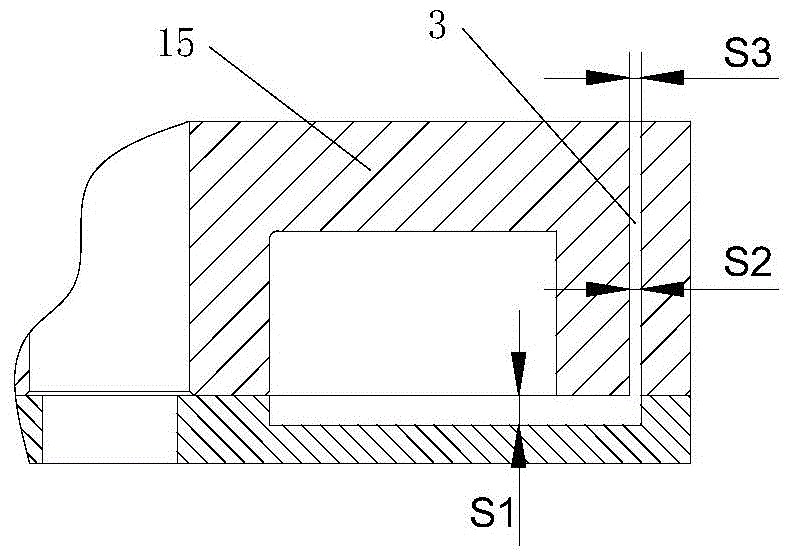

[0099] Such as Figure 5 As shown, in this embodiment, the oil separator 18 of the low back pressure rotary compressor 100 is disposed outside the casing 10 , and the oil separator 18 communicates with the exhaust hole 6 . The oil pool 5 is arranged at the bottom of the oil separator 18, the inlet of the slide vane oil supply path 3 communicates with the oil pool 5 arranged in the oil separator 18, and the slide vane oil supply path 3 is connected to the oil pool 5 and the slide vane cavity 2 The oil supply pipe, the outlet of the slide vane oil supply path 3 , that is, the oil supply hole of the slide vane cavity 2 is located in the middle of the slide vane cavity 2 .

[0100] Among them, the distance between the oil supply hole and the bottom of the vane chamber 2 is d, and the height of the vane chamber 2 is H, and there are:

[0101] 0

[0102] The rest are the same as in Embodiment 1 and will not be repeated here.

Embodiment 3

[0104] Such as Figure 7 and Figure 9 As shown, in this embodiment, the difference from Embodiment 1 and Embodiment 2 is that the compression mechanism has two cylinders up and down, that is, the cylinder assembly includes an upper cylinder 12a, a lower cylinder 12b and a middle partition, and the middle partition is arranged on the upper Between the cylinder 12a and the lower cylinder 12b, correspondingly, the slide chamber 2 also includes the upper slide chamber 2a and the lower slide chamber 2b, and the slide chamber 2a of the upper cylinder 12a and the slide chamber 2b of the lower cylinder 12b are connected with the oil pool respectively. In addition, the oil supply path 3 of the slide chamber also includes an upper oil supply path 3a and a lower oil supply path 3b, ….

[0105] That is to say, in this embodiment, the upper cylinder 12a and the lower cylinder 12b are respectively analyzed as independent cylinders, the volume V of the slide cavity of the two cylinders, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com