Reciprocating-type hydraulic transmission coupling

A hydraulic transmission and transmission shaft technology, applied in the direction of couplings, fluid couplings, clutches, etc., can solve the problems of low transmission efficiency, low control sensitivity, long response time, etc., and achieve low heat generation, high transmission efficiency, and control Responsive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings, so as to more clearly show the concept of the present invention, the technical problems to be solved, the technical features of the technical solutions and the technical effects brought about by them. However, it should be clear that the description of the following embodiments is illustrative and does not constitute a specific limitation to the present invention. The present invention includes but is not limited to the following embodiments. Without departing from the principle and concept of the present invention, any changes, modifications, substitutions and modifications to the following embodiments shall fall within the protection scope of the present invention.

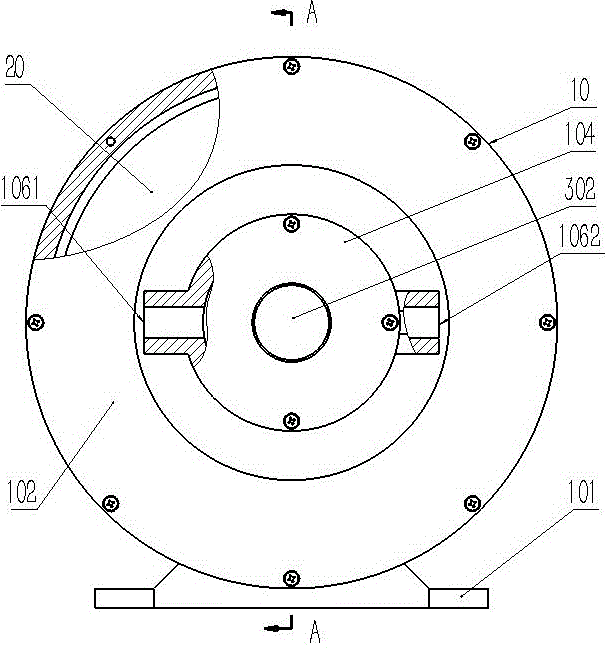

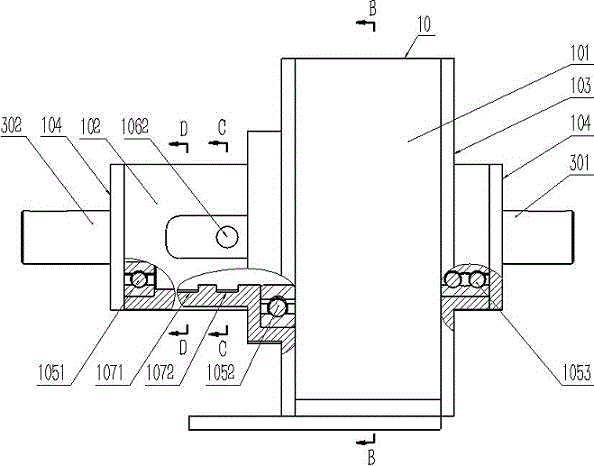

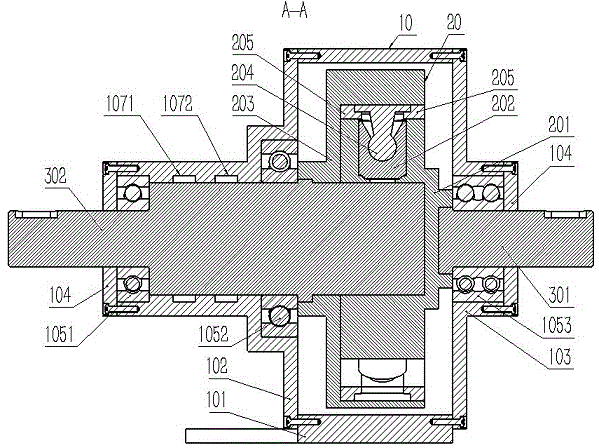

[0019] A reciprocating hydraulic transmission coupling, including: hydraulic control circuit, transmission oil and main engine; figure 1 with figure 2 As shown, the host includes: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com