Wiring cutter head, method for preparing electric smelting pipe fitting by using wiring cutter head and obtained wire exposed type electric smelting pipe fitting

An electrofusion pipe fitting and wire-exposed technology, which is applied in the directions of pipes/pipe joints/pipes, mechanical equipment, and pipe connection arrangements, can solve the problems of deep wiring depth of the cutter head, more exposed resistance wires, and large ovality. The effect of reducing the depth of placement, reasonable layout and small ovality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

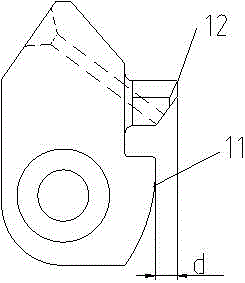

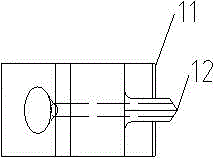

[0052] The wiring cutter head 1 of the present invention is as Figure 4-7 As shown, including cutter body 11, one side of cutter body 11 (see Figure 4 Shown on the right side) is provided with a knife tip 12, below the knife tip 12 is a tool setting surface 13, there is a gap between the tool setting surface 13 and the tool tip 12, and the other side of the tool body 11 (see Figure 4 The upper part shown on the left side) is provided with a copper wire hole 14, and the copper wire hole 14 extends toward the knife tip 12 and reaches the lower side of the knife tip 12.

[0053]The side of the tool point 12 on the tool setting surface 13 is a plane, and the front side of the tool setting surface 13 (that is, the tip side of the tool tip 12, which is also used for rolling the flash 22 during use) is in contact with the tool The horizontal distance d between the tips of the tip 12 is 0.1 mm, and one end of the tool setting surface 13 is a beveled surface 15 inclined toward the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com