Encapsulation method of optical fiber sensing coil

A technology of a sensing ring and a packaging method, which is applied to measurement devices, instruments, Sagnac effect gyroscopes, etc., can solve the problems of insufficient selection of packaging materials for optical fiber sensing rings, and reduce the number of fiber optic gyroscopes. Drift error, reducing temperature drift error, and uniform dipping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

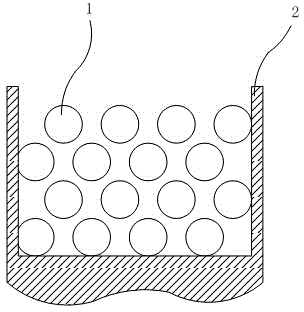

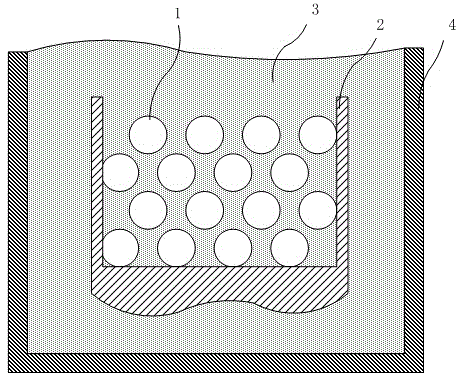

[0029] (1) Wrap the polarization-maintaining optical fiber on the optical fiber sensing ring skeleton in a standard four-level symmetrical manner, and there are gaps between the optical fibers.

[0030] (2) The optical fiber sensing ring is dipped in glue. The glue used for primary packaging is epoxy resin with a viscosity of 1000cPS and a thermal conductivity of 0.55W / M*K.

[0031] (3) The curing method of primary packaging is heat curing, the curing temperature is 80 degrees, and the curing time is 6 hours.

[0032] (4) After the optical fiber sensing ring is cured, remove the skeleton from the ring. Bonded in the protective cover of the ring, the glue used for bonding is epoxy resin, and the modulus is 4000MPa.

[0033] (5) The glue used for secondary packaging is a low-modulus gel with a modulus of 0.8MPa and a thermal conductivity of 0.2 W / M*K.

[0034] When the optical fiber sensing loop packaged in this way is assembled into the fiber optic gyroscope system, the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com