Measuring method for adhesive strength of flexible substrate material coating

A flexible substrate, adhesion strength technology, applied in the direction of measuring devices, analysis materials, instruments, etc., can solve the problems of inaccurate test results, inability to guarantee complete separation of coating and substrate, coating peeling off, etc., to overcome the strong subjectivity , simple operation, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

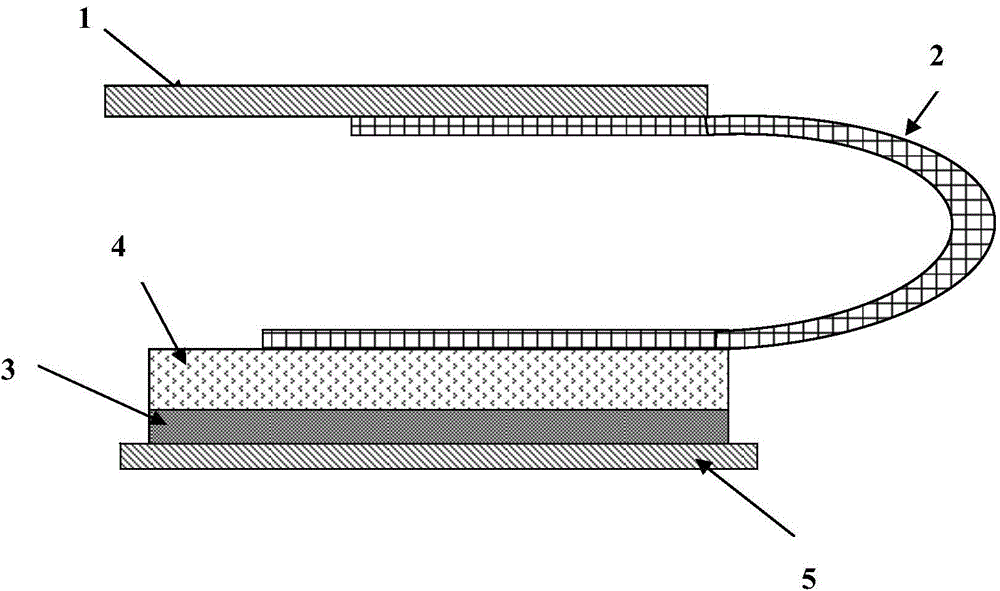

Image

Examples

Embodiment

[0042] Prepare the positive electrode sheet to be tested: 100 parts by weight of LiCoO 2, 2.5 parts by weight of binder PVDF, and 3 parts by weight of conductive agent acetylene black were added to 65 parts by weight of NMP solvent, and then stirred in a vacuum mixer to form a uniform positive electrode slurry. The slurry was evenly coated on one side of an aluminum foil with a width of 400 mm and a rear 20 μm, and then dried at 120° C., rolled and cut to obtain a positive electrode sheet with a size of 140 mm×50 mm.

[0043] Prepare the negative pole sheet to be tested: 100 parts by weight of negative electrode active material natural graphite, 1.0 parts by weight of binder PVDF and 1.0 parts by weight of conductive agent carbon black are added to 120 parts by weight of NMP solvent, then stirred in a vacuum mixer to form Stable and uniform negative electrode slurry. The slurry was evenly coated on one side of a copper foil with a width of 400 mm and a thickness of 10 μm, dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com