An intelligent control method and device for asphalt gravel spreading by a synchronous gravel sealing vehicle

A technology of asphalt gravel and synchronous gravel, applied in the direction of electric controllers, controllers with specific characteristics, etc., can solve problems such as difficulty in establishing accurate mathematical models, difficulty in ensuring spreading accuracy, and poor controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below in conjunction with accompanying drawing.

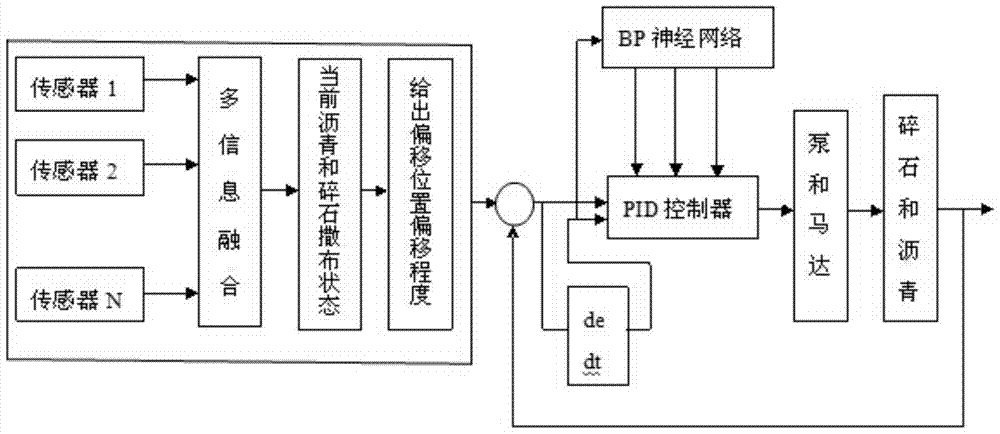

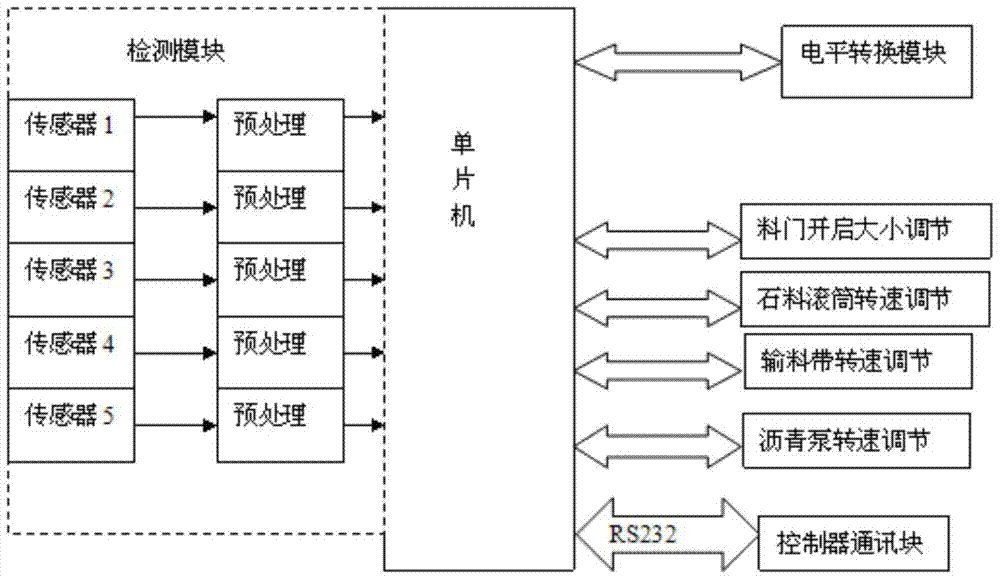

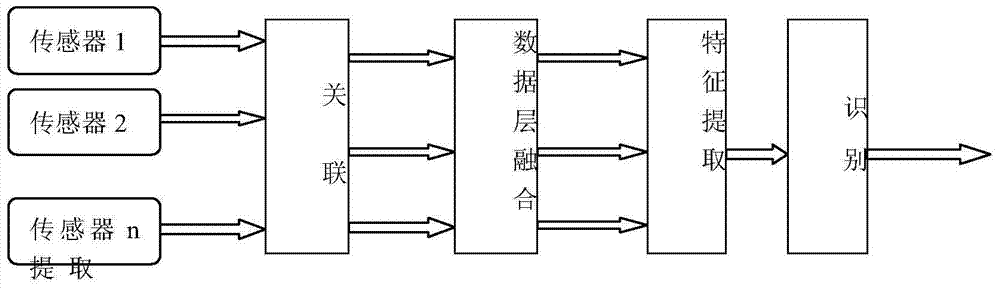

[0057] Such as Figure 1 to Figure 5 As shown, an intelligent control method for asphalt gravel spreading by a synchronous gravel sealer vehicle, the method firstly uses a sensing system mainly composed of ultrasonic sensors, pressure sensors, speed sensors, and infrared sensors to detect the surrounding environment information, and the detected The information is analyzed through the data layer, feature layer, and decision-making layer to determine the final execution data, and the data is analyzed according to the respective information weight adjustments; secondly, the BP neural network algorithm is introduced into the conventional PID controller, and the amount of stones detected by the sensor, the roller Speed, transmission belt speed, pump displacement, pump speed, and spray beam asphalt pressure form an information neural network. Using the self-learning ability of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com