Motor for directly driving electric drum

An electric drum and drum technology, which is applied to electrical components, electromechanical devices, magnetic circuit rotating parts, etc., can solve the asymmetry of each phase of the six-phase doubly salient motor, and no research reports on the six-phase doubly salient motor have been retrieved. problems, to achieve the effect of reducing copper consumption, improving reliability and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

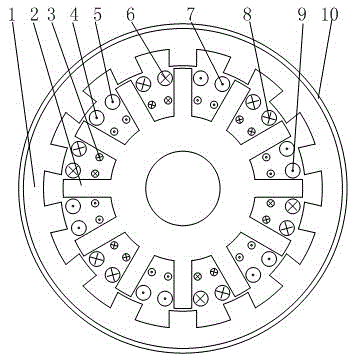

[0034] Such as figure 1 The shown motor for a direct drive electric drum includes a stator core, a rotor core, a drum wall, an excitation winding, an armature winding and a shaft, etc., the motor is of an outer rotor structure, and the outer side of the rotor core is fixed to the drum wall; The number of poles of the motor stator is 6N, the pole arc coefficient of the stator is 0.333, the pole number of the rotor is 7N, and the pole arc coefficient of the rotor is 0.5.

Embodiment 2

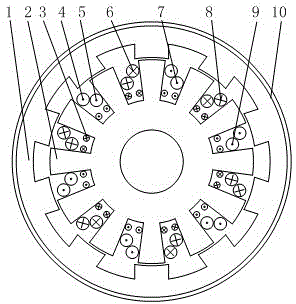

[0036] Such as figure 2 The difference between the motor for fixed direct drive electric drum shown in this embodiment and that of Embodiment 1 is that the number of poles of the stator and rotor is 6N / 5N, the pole arc coefficient of the stator is 0.4, and the pole arc coefficient of the rotor is 0.5.

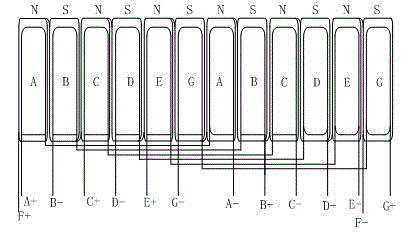

[0037] Such as image 3 The winding method of each winding of the high-reliability motor for the direct-drive electric drum is shown. There is an armature coil and an excitation coil on each stator pole, and the armature coil is divided into A-phase coil and B-phase coil in turn along the circumferential direction. Coil, C-phase coil, D-phase coil, E-phase coil and G-phase coil, so cycle N times, and the winding directions of adjacent armature coils are opposite; each excitation coil on the stator pole has the same number of turns, and The winding directions of adjacent excitation coils are opposite.

[0038] Such as Figure 4 The connection method between the motor winding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com