Eyedrops packaging bottle

A technology for packaging bottles and eye drops, which is applied in the directions of drug packaging, packaging, and packaged food, etc., can solve problems such as side effects, accidental eye damage, and increase in the number of parts of eye drops, avoiding accidental pollution and controlling material costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A detailed description will be given below of specific embodiments of the present invention according to the accompanying drawings.

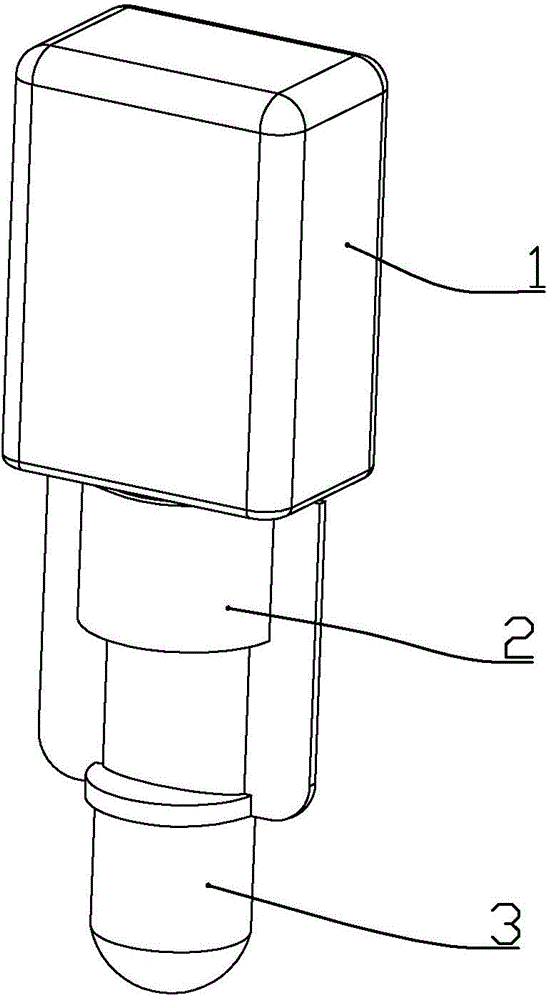

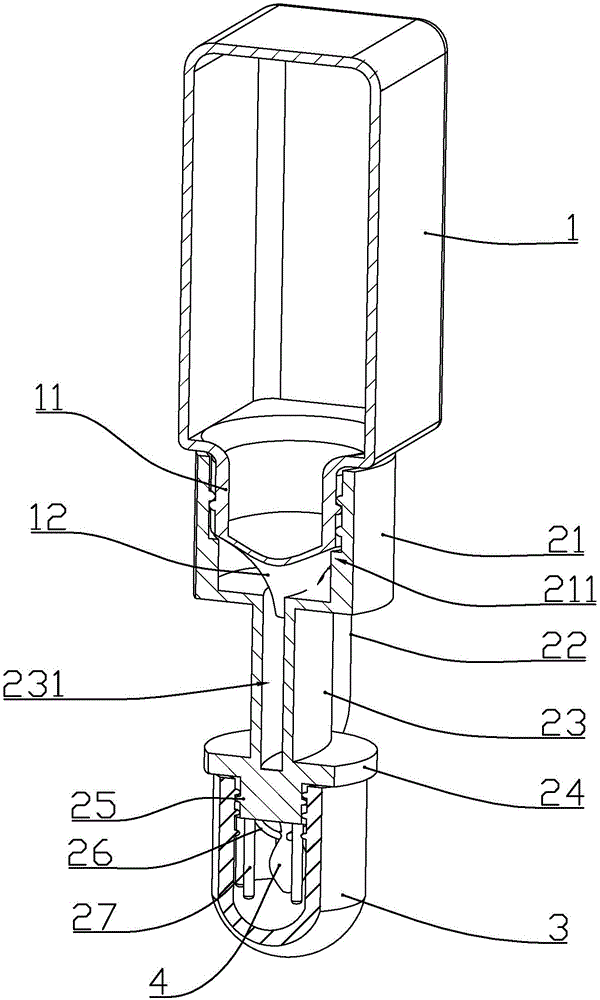

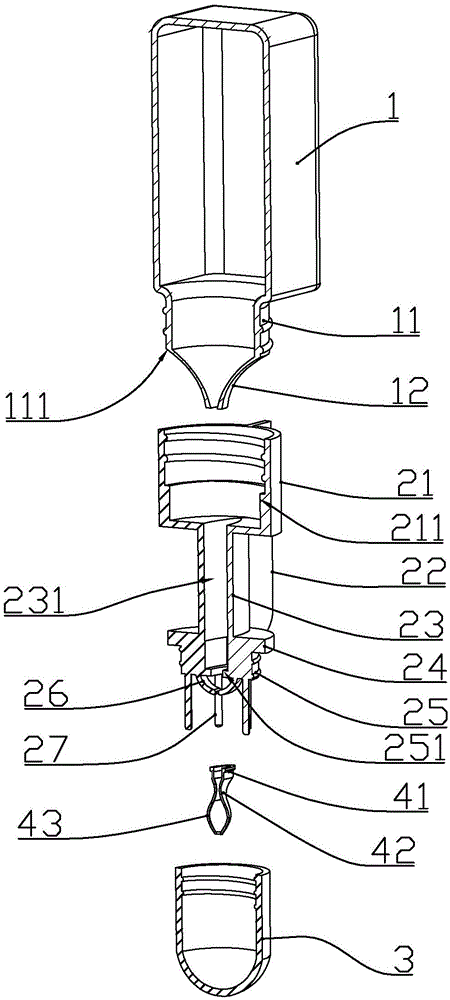

[0017] according to Figure 1 to Figure 3 As shown, a kind of eye drops packaging bottle described in this embodiment includes a bottle body 1, a dropper 4 and a bottle cap 3, and a pressing assembly 2 is connected between the bottle body and the dropper; The bottle body is integrally molded from elastic soft plastic or rubber. A pressing assembly connecting portion 11 is integrally formed at the mouth of the bottle, and a tapered pipe portion 12 is integrally formed at the outer end of the pressing assembly connecting portion.

[0018] The pressing assembly is integrally molded by elastic hard plastic, and the pressing assembly includes a bottle body connecting part 21, a pressing part 23, a limiting plate 24 and a bottle cap connecting part 25 which are integrally connected in sequence. There is an oval-shaped lumen 231 in the section,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com