Ultrasonic spray near drying type electrical discharge machining method and device

An ultrasonic spray and processing device technology, applied in the field of electric discharge machining, can solve the problems of affecting the processing effect, unfavorable long-term stable processing, poor continuity, etc., and achieve the effect of improving material removal rate, processing efficiency and processing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

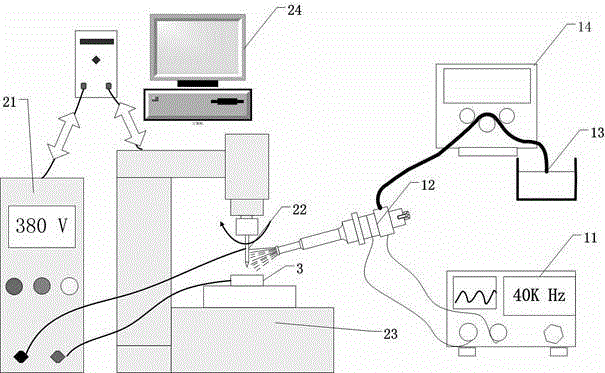

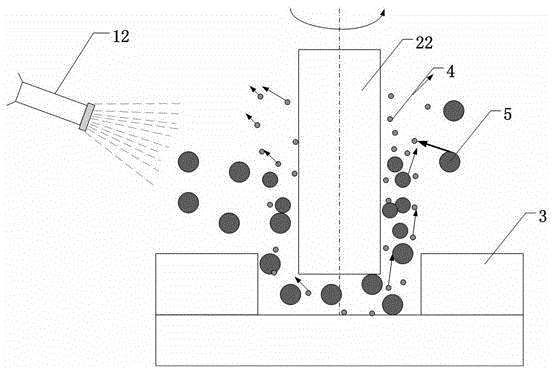

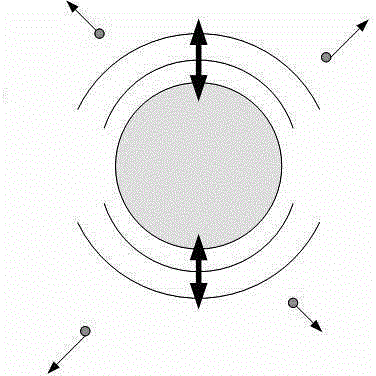

[0025] Figure 1 to Figure 6 The reference numerals in the figure are: ultrasonic power supply 11; ultrasonic transducer 12; working fluid storage 13; constant current pump 14; pulse power supply 21; processing electrode 22; processing machine tool 23; industrial computer 24; workpiece 3; processing waste 4 ; Atomized particles 5.

[0026] like Figure 1 to Figure 2 As shown, a quasi-dry electric discharge machining method of ultrasonic spraying, the workpiece 3 is subjected to electric discharge machining through an electric discharge machining device, and at the same time, the workpiece 3 is subjected to ultrasonic spraying through an ultrasonic atomization device.

[0027] like Figure 1 to Figure 2 As shown, the side of the workpiece 3 is ultrasonically sprayed by an ultrasonic atomizing device.

[0028] like Figure 1 to Figure 2 As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com