Textile dyeing wastewater treatment and reclamation technique

A wastewater treatment, textile printing and dyeing technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as unsatisfactory effect, high chroma, and shortened membrane service life , to achieve the effect of enhancing competitive advantage, high pollutant concentration, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

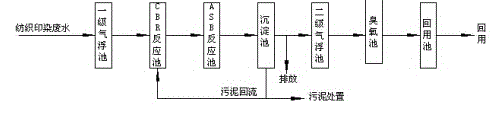

Method used

Image

Examples

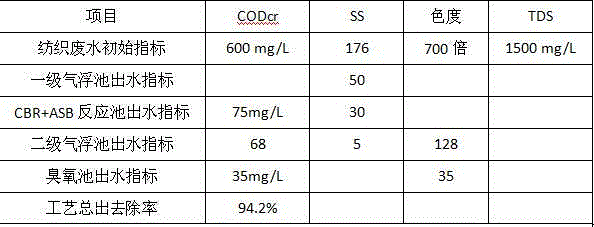

Embodiment 1

[0021] In conjunction with the accompanying drawings, the technical solution of the present invention is further described. It should be understood that these examples are only used to illustrate the present invention, not to limit the application scope of the present invention.

[0022] The waste water is pumped into the primary air flotation tank through the lifting pump of the regulating tank, the reflux ratio of the air flotation tank is adjusted to 10%, and the air holding pressure is controlled to 2.0MPa, so that the impurities in the waste water are adhered by the tiny bubbles formed and brought to the liquid The scum is formed on the surface, and then the scum is collected and discharged by the scum scraper to achieve the purpose of removing impurities in the wastewater, and the dissolved oxygen content in the wastewater is increased by air flotation.

[0023] The effluent from the first-stage air flotation directly enters the CBR reaction tank, and degrades the organi...

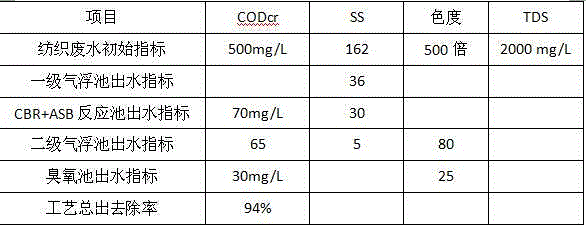

Embodiment 2

[0029] The waste water is pumped into the primary air flotation tank through the lifting pump of the regulating tank, the reflux ratio of the air flotation tank is adjusted to 40%, and the air holding pressure is controlled to 3.5MPa, so that the impurities in the waste water are adhered by the tiny bubbles formed and brought to the liquid The scum is formed on the surface, and then the scum is collected and discharged by the scum scraper to achieve the purpose of removing impurities in the wastewater, and the dissolved oxygen content in the wastewater is increased by air flotation.

[0030] The effluent from the first-stage air flotation directly enters the CBR reaction tank, and degrades the organic matter in the wastewater through the domesticated and membrane-hanging composite membrane mud reactor. Control the volume load in the CBR reaction tank to 5kgCOD / (m 3 d), the volume load of the ASB reaction tank is 1kgCOD / (m 3 d), control the dissolved oxygen concentration in th...

Embodiment 3

[0036] The waste water is pumped into the primary air flotation tank through the lifting pump of the regulating tank, the reflux ratio of the air flotation tank is adjusted to 20%, and the air holding pressure is controlled to 3MPa, so that the impurities in the waste water are adhered by the tiny bubbles formed and brought to the liquid surface , Form scum, and then collect and discharge the scum through the scum scraper to achieve the purpose of removing impurities in the wastewater, and increase the dissolved oxygen content in the wastewater through air flotation.

[0037] The effluent from the first-stage air flotation directly enters the CBR reaction tank, and degrades the organic matter in the wastewater through the domesticated and membrane-hanging composite membrane mud reactor. Control the volume load in the CBR reaction tank to 3kgCOD / (m 3 d), the volume load of the ASB reaction tank is 0.7kgCOD / (m 3 d), control the dissolved oxygen concentration in the aerobic rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com