Method for treating sewage by using ozone-containing tail gas

A technology of ozone tail gas and oxidation treatment, applied in the direction of oxidized water/sewage treatment, filtration treatment, sedimentation treatment, etc., can solve the problems of environmental pollution and high cost, and achieve the effect of reducing cost, reducing consumption and improving water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

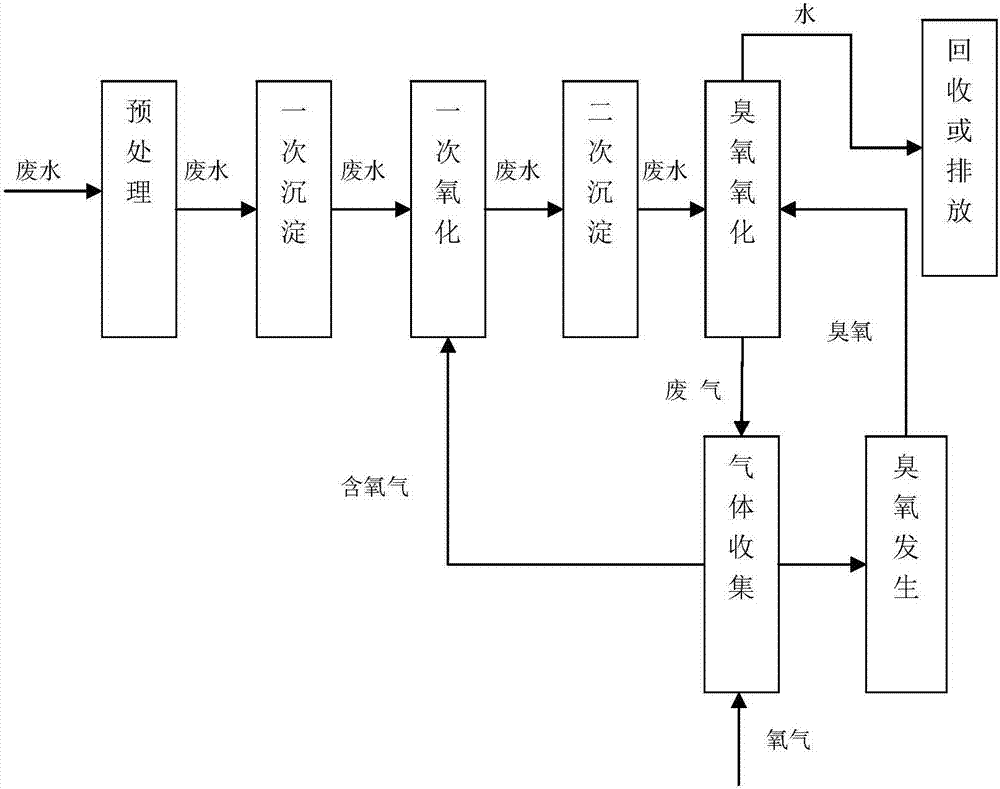

Image

Examples

Embodiment 1

[0075] The pretreatment is that the sewage passes through the grid mesh filter device, the regulating tank, and the cooling tower in sequence. Use the grid mesh to filter the waste water after removing fibrous substances such as textile fibers with a particle size greater than 1.5mm, and then enter the regulating tank. In the adjustment tank, adjust the parameters such as water volume and pH value, add a certain amount of water or divert a certain amount of printing and dyeing wastewater to achieve the purpose of adjusting the water volume. The water volume requirements are mainly determined according to the treatment volume and impurity content of the printing and dyeing wastewater; The pH value of the aqueous phase is between 6.5-7.5. Pump the wastewater from the regulating tank into the cooling tower to moderately cool it down to 35°C.

[0076] After the wastewater is pretreated, a sedimentation treatment is carried out. The pH value of the primary sedimentation tank is co...

Embodiment 2

[0084] Mix 600L of ozone recovery gas with air at a ratio of 1:3 (volume) to obtain 2400L of mixed gas. The mixed gas, as oxygen-containing gas K, passes through the first group of gas explosion devices in batches, and then enters the primary oxidation tank. The second group of gas explosion devices, the third group of gas explosion devices, the fourth group of gas explosion devices, and the fifth group of gas explosion devices Explosion device, let in air, and the flow rate of each group of explosion device is 100L / h. The residence time of sewage in the primary oxidation tank is 24 hours.

[0085] After oxidation treatment, the sewage enters the secondary precipitation treatment and ozone oxidation treatment for further treatment.

[0086] Sampling and testing at the outlet of the ozone oxidation tank showed that the COD was 35mg / L water, the BOD was 10mg / L, the ammonia nitrogen was 8mg / L, the chroma was removed, and the SS was 11mg / L.

Embodiment 3

[0088]Mix 900L of ozone oxidation recovery gas with air at a ratio of 1:5 (volume) to obtain 5400L of mixed gas. The mixed gas is passed into the primary oxidation tank as the oxygen-containing gas K through the first group of explosion devices and the third group of explosion devices, and the flow rate is 140L / h. The second group of gas explosion devices, the fourth group of gas explosion devices, and the fifth group of gas explosion devices are fed with air at a rate of 100L / h. The residence time of sewage in the primary oxidation tank is 18 hours.

[0089] After oxidation treatment, the sewage enters the secondary precipitation treatment and ozone oxidation treatment for further treatment.

[0090] Sampling and testing at the outlet of the ozone oxidation tank showed that the COD was 33mg / L water, the BOD was 12mg / L, the ammonia nitrogen was 10mg / L, the chroma was removed, and the SS was 12mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com