Nano composite photocatalyst and preparation method thereof

A nanocomposite and photocatalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of low light utilization rate and difficult recycling, so as to improve catalytic efficiency and be suitable for large-scale Large-scale industrial production, the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A method for preparing a nanocomposite photocatalyst, comprising the following steps:

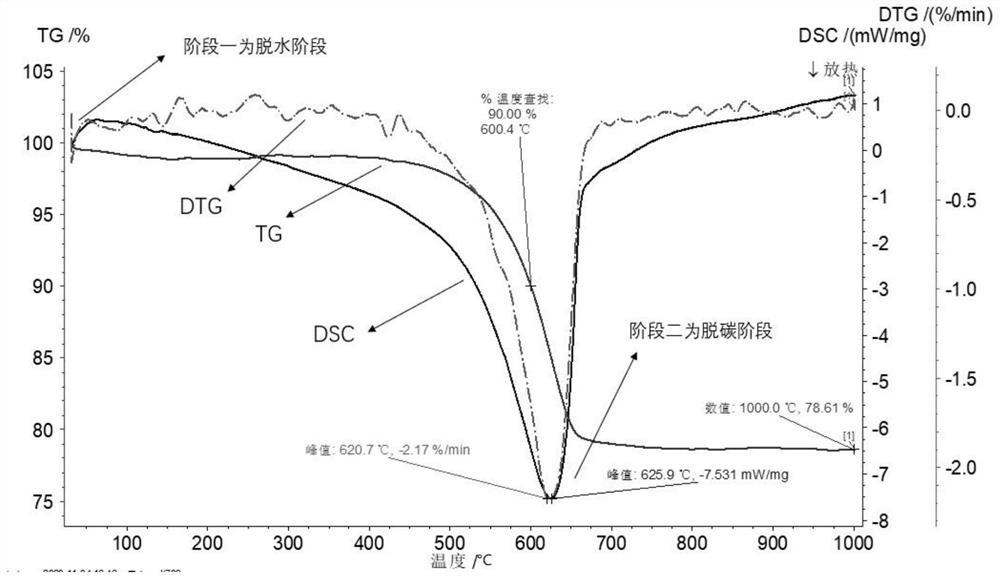

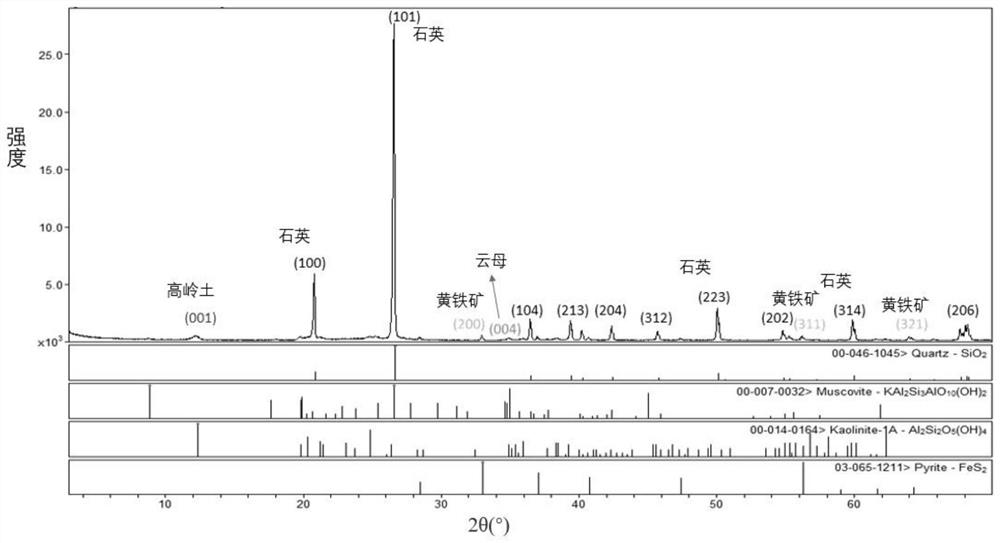

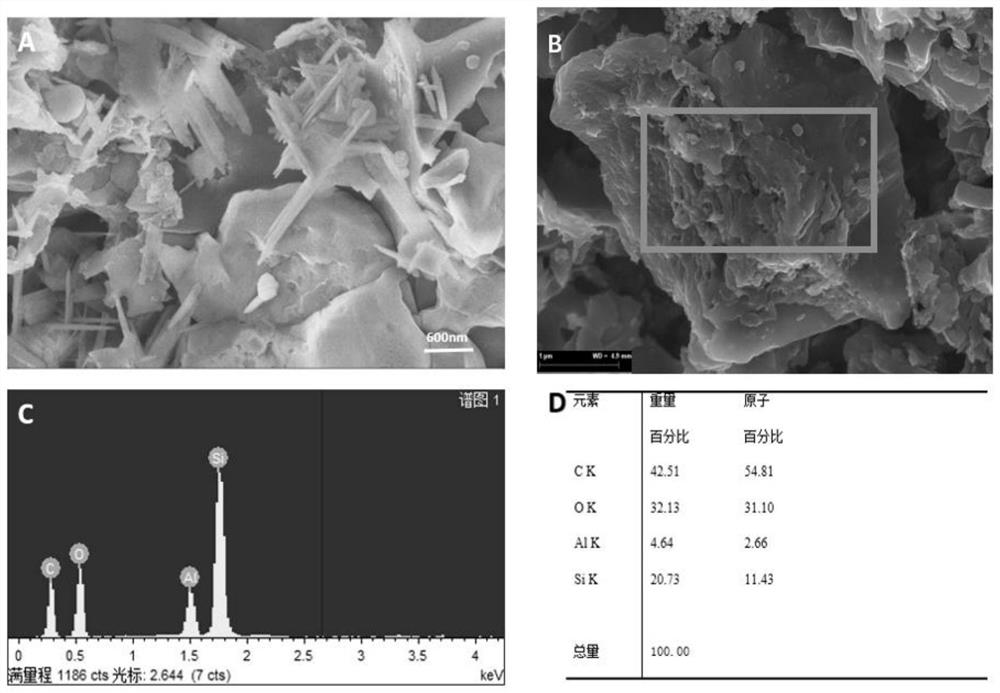

[0053] 1. Use the new minerals analyzed above as raw materials, dry and roast at 250°C for 4 hours to remove organic carbon, and obtain dry mineral powder after breaking up;

[0054] 2. Mix butyl titanate and absolute ethanol at a mass ratio of 1:10, and stir evenly to obtain a butyl titanate solution;

[0055] 3. Mix the mineral powder and butyl titanate in the butyl titanate solution evenly according to the mass ratio of 2:1, add distilled water drop by drop, and stir slowly until the mixed solution is viscous to obtain a gel;

[0056] 4. Place the gel in a blast drying oven for rapid drying at 105°C, then place it in a nitrogen atmosphere furnace for calcination at 400°C for 6 hours, then take it out and break it up to obtain the nanocomposite photocatalyst;

[0057] The electron micrograph of the composite photocatalyst that embodiment 1 obtains is as Figure 5 shown. Among th...

Embodiment 2

[0059] A method for preparing a nanocomposite photocatalyst, comprising the following steps:

[0060] 1. Use the new minerals analyzed above as raw materials, dry and roast at 450°C for 3 hours to remove organic carbon, and obtain dry mineral powder after breaking up;

[0061] 2. Mix butyl titanate and absolute ethanol at a mass ratio of 2:5, and stir evenly to obtain a butyl titanate solution;

[0062] 3. Mix the mineral powder and butyl titanate in the butyl titanate solution evenly at a mass ratio of 1:1, add distilled water drop by drop, and stir slowly until the mixture is viscous and a gel is obtained;

[0063] 4. Place the gel in a blast drying oven for rapid drying at 150°C, then place it in a nitrogen atmosphere furnace for calcination at 600°C for 1 hour, then take it out and break it up to obtain the nanocomposite photocatalyst;

[0064] The electron micrograph of the composite photocatalyst that embodiment 2 obtains is as Image 6 shown. Among them, the particle...

Embodiment 3

[0066] A method for preparing a nanocomposite photocatalyst, comprising the following steps:

[0067] 1. Use the new minerals analyzed above as raw materials, dry and roast at 400°C for 3 hours to remove organic carbon, and obtain dry mineral powder after breaking up;

[0068] 2. Mix butyl titanate and absolute ethanol at a mass ratio of 1:5, and stir evenly to obtain a butyl titanate solution;

[0069] 3. Mix the mineral powder and butyl titanate in the butyl titanate solution evenly according to the mass ratio of 1:0.8, add distilled water drop by drop, and stir slowly until the mixed solution is viscous to obtain a gel;

[0070] 4. Place the gel in a blast drying oven at 120°C for quick drying, then place it in a nitrogen atmosphere furnace for calcination at 500°C for 3 hours, then take it out and break it up to obtain the nanocomposite photocatalyst;

[0071] The electron micrograph of the composite photocatalyst that embodiment 1 obtains is as Figure 7 As shown: the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Degradation rate | aaaaa | aaaaa |

| Degradation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com