an alpha-fe 2 o 3 -zno/gangue composite photocatalyst and preparation method and application thereof

A technology of -fe2o3-zno and coal gangue, which is applied in the field of photocatalyst preparation and can solve problems that have not been reported yet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

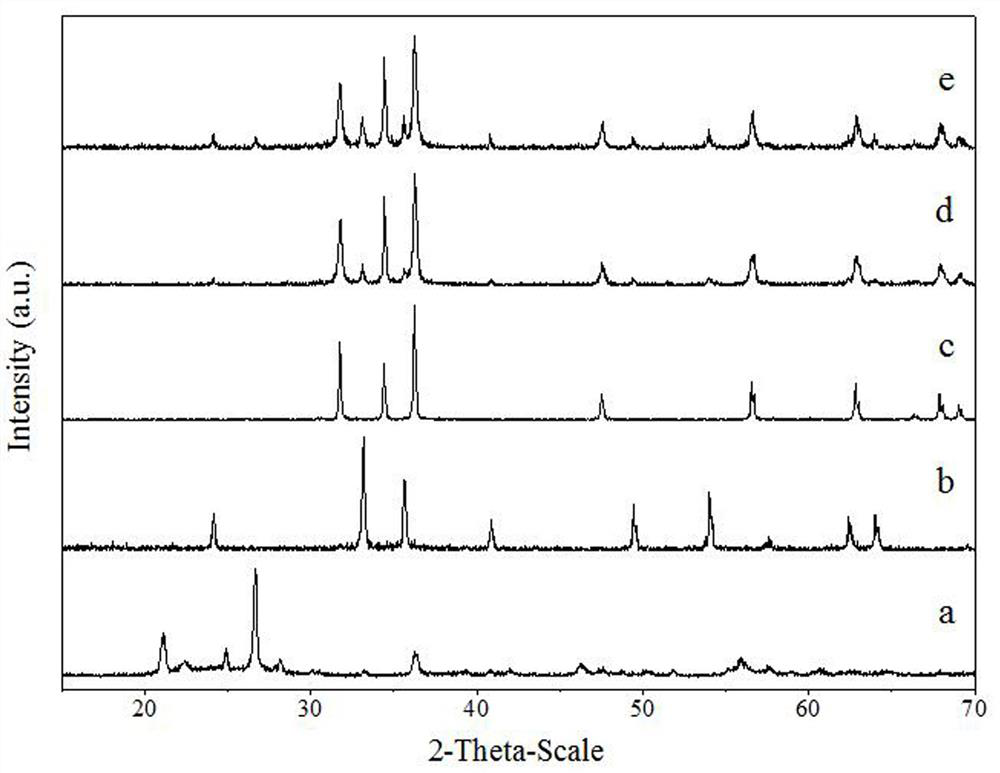

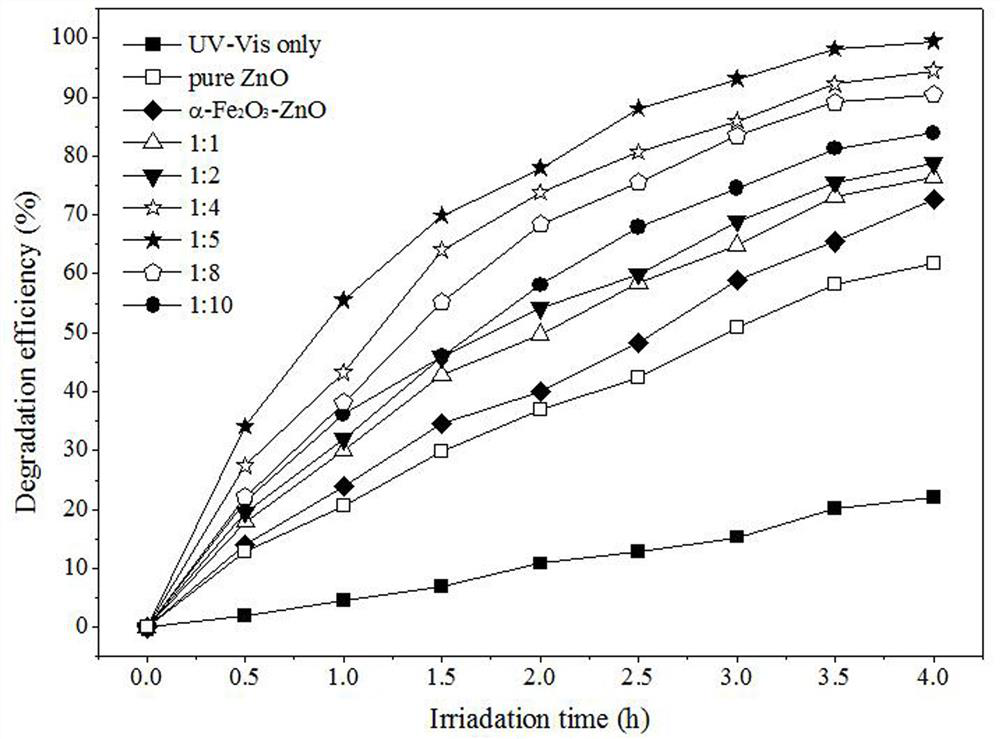

[0045] Coal gangue from the Pingshuo mining area in Shanxi was crushed and fully ground, passed through a 200-mesh sieve, and calcined at 700 °C for 2 h for later use. At the same time, the preparation of Fe 3+ Iron salt solution with an ion concentration of 0.2 mol / L, Zn 2+ Zinc salt solution with ion concentration of 0.1 mol / L, 6 mol / L and 0.1 mol / L sodium hydroxide aqueous solution are used for later use.

[0046] 20 mL of zinc sulfate aqueous solution (Zn 2+ The ion concentration is 0.1 mol / L) and the calculated amount of ferric nitrate aqueous solution (Fe 3 + ion concentration of 0.2 mol / L) into a three-neck flask, distilled water to a volume of 100 mL, added 5 g of pretreated coal gangue powder, stirred magnetically for 1 h, and slowly added 6 mol / L and 0.1 mol / L of sodium hydroxide aqueous solution, the pH value of the reaction system was adjusted to 9 by controlling the addition of sodium hydroxide aqueous solution, and boiling refluxed for 3 h. After suction fi...

Embodiment 2~6

[0047] Embodiment 2~6 and comparative example 1~4

[0048] The operation steps of Examples 2-6 and Comparative Examples 1-4 are the same as those of Example 1, the difference is only in the type of zinc salt and iron salt used, the amount of iron salt aqueous solution, the coal gangue calcination temperature, the coal gangue amount and the pH of the reaction system values, as shown in Table 1.

[0049] Table 1 Examples 2~6 and Comparative Examples 1~4

[0050] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com