An electrocatalytic activity regulation method based on inert ion intercalation

An electrocatalysis and ion technology, which is applied in the field of environmental pollution control, can solve the problems of limited control degree of electrocatalytic electrodes, limited control methods and means, complex types of pollutants, etc., and achieves simple processing method, high feasibility and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

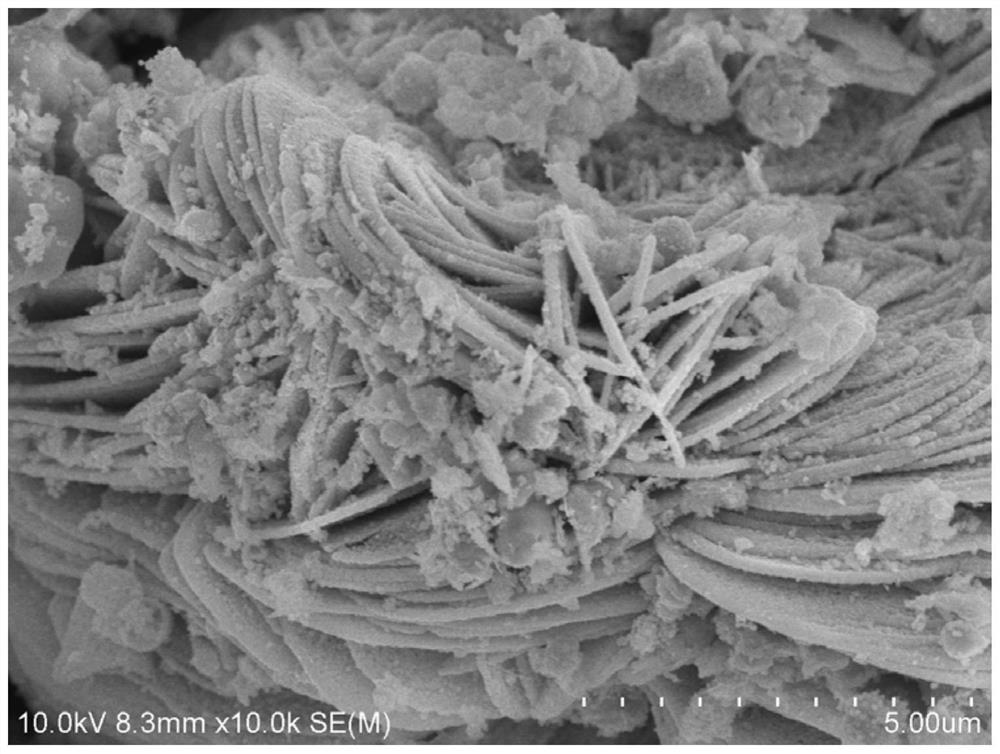

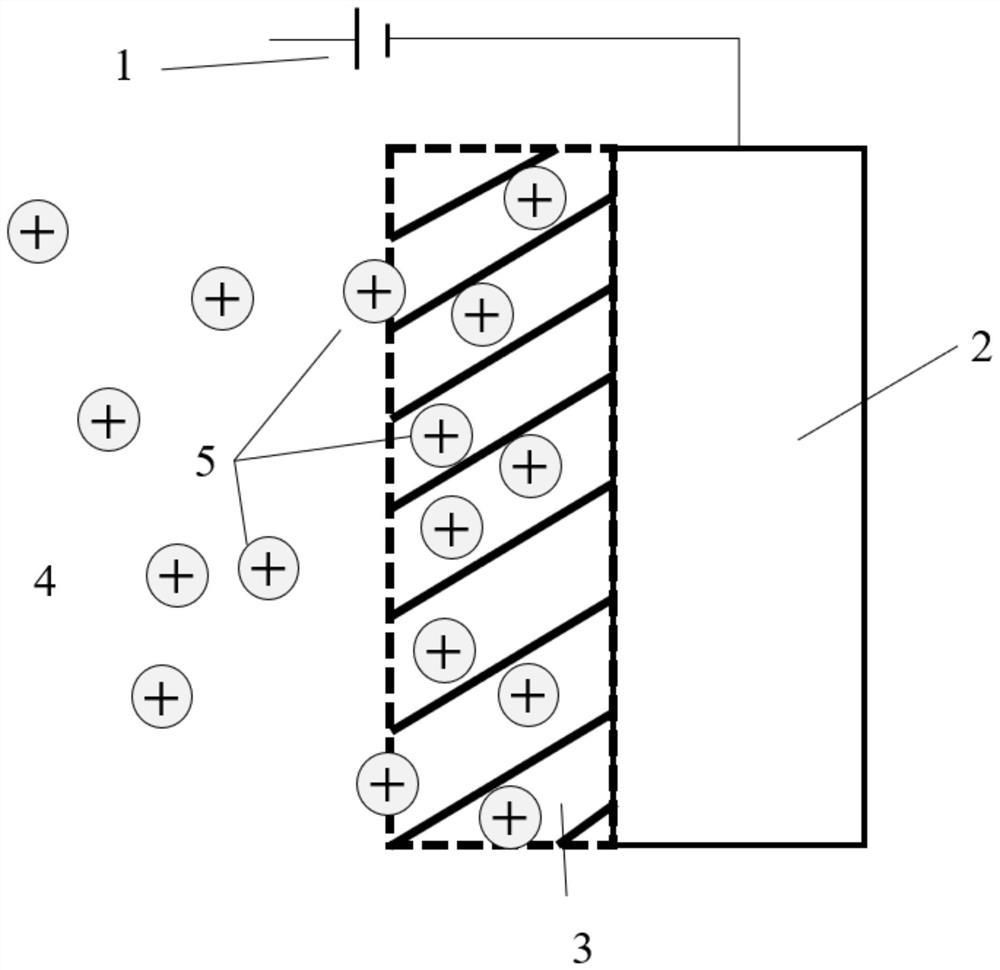

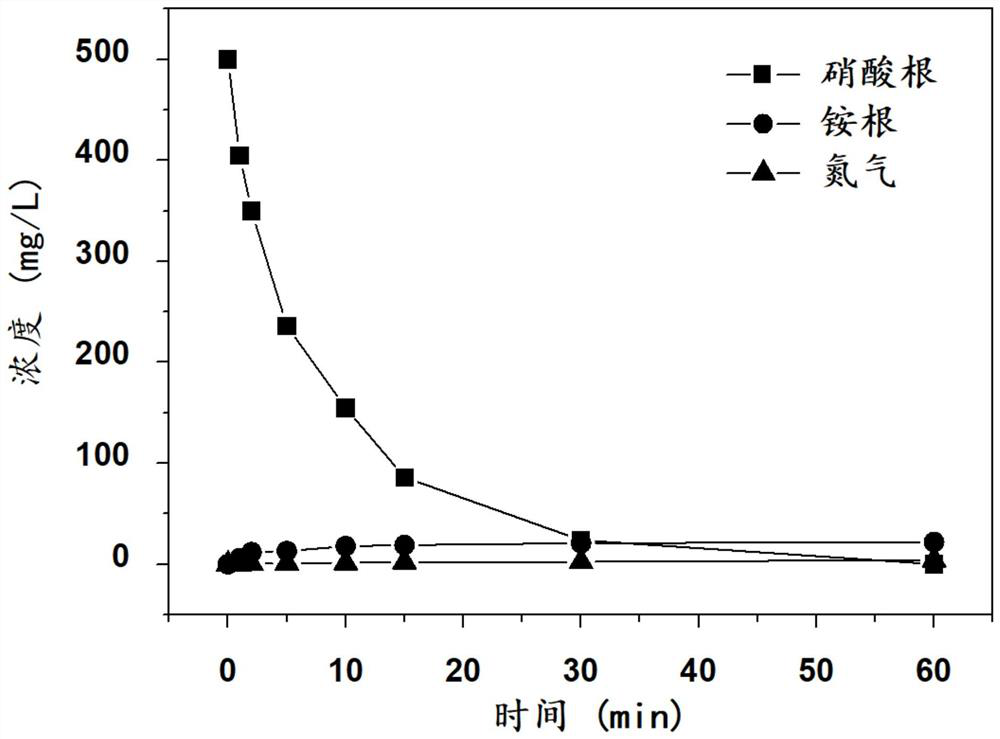

Embodiment 1

[0028] First, put the stainless steel electrode with cerium oxide film on the surface as the cathode, and the graphite electrode as the anode, connect the positive and negative poles of the DC pulse power supply to the positive and negative poles respectively, and set the pulse current density to 0.5mA / cm 2 , start the power supply to process the metal electrode, and continue the treatment for 5 minutes, so that the oxide film is properly pore-formed and a layered defect state structure is formed to form a defect state electrode; the next step is to expand the defect state electrode, and use the defect state electrode as the anode , the graphite electrode is used as the cathode, and 1 mol / liter of sodium sulfate, 0.5 mol / liter of sulfuric acid, 0.02 mol / liter of potassium fluoride, 0.1 mol / liter of triethylamine, and 0.22 mol / liter of potassium thiocyanate are added to the electrolytic cell as electrolytes, Connect the positive and negative poles of the DC pulse power supply to...

Embodiment 2

[0031] First, put the stainless steel electrode with aluminum oxide film on the surface as the cathode and the graphite electrode as the anode in the electrolytic cell, and set the pulse current density to 10mA / cm 2, start the power supply to process the metal electrode, and continue the treatment for 10 minutes. With the electrode in the defect state as the anode and the graphite electrode as the cathode, add 1 mol / L of potassium sulfate, 0.5 mol / L of sulfuric acid, and 0.02 mol / L of potassium fluoride into the electrolytic cell. , triethylamine 0.1 mol / liter, potassium thiocyanate 0.22 mol / liter as the electrolyte, set the pulse current density to 100mA / cm 2 , start the power supply and continue processing for 30 seconds, change the position of the cathode and anode, and set the current density to 1.0mA / cm 2 , the pulse treatment time was 24 hours, and other treatment conditions were similar to those in Example 1, so that no further details were given to obtain a potassium i...

Embodiment 3

[0034] Firstly, place a stainless steel electrode with a silicon oxide film on its surface in the electrolytic cell as the cathode, and a graphite electrode as the anode, and set the pulse current density to 2.5mA / cm 2 , start the power supply to process the metal electrode, and continue the treatment for 7 minutes. With the electrode in the defect state as the anode and the graphite electrode as the cathode, add 1 mol / L of calcium nitrate, 0.5 mol / L of sulfuric acid, and 0.02 mol / L of potassium fluoride into the electrolytic cell. , triethylamine 0.1 mol / liter, potassium thiocyanate 0.22 mol / liter as the electrolyte, set the pulse current density to 100mA / cm 2 , start the power supply and continue processing for 15 seconds, change the position of the cathode and anode, and set the current density to 0.5mA / cm 2 , the pulse treatment time was 18 hours, and other treatment conditions were similar to those in Example 1 so that no further details were given to obtain a calcium ion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com