Method for improving phosphorus release rate of iron phosphate-containing sludge during anaerobic fermentation

A technology for sludge anaerobic fermentation and phosphorus release, which is applied in biological sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of phosphorus not being released, and achieve increased phosphorus concentration, good Maneuverability and controllability, effect of overcoming re-sedimentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Take 400mL of concentrated FePO-free 4 Biological sludge, containing FePO 4 The mixed sludge (total suspended solids concentration is 11.20g / L, volatile suspended solids concentration is 7.11g / L) is put into different reactors, and Na 2 S makes its concentration 0.04gNa 2 S / gTSS was anaerobically fermented in a closed reactor at 35°C for 7 days. At the same time without adding Na 2 The reactor of S served as a control.

[0024] (2) Sampling once every 24 hours, measuring the orthophosphate (PO 4 3- -P), concentrations of dissolved organic carbon (STOC), volatile fatty acids (VFA).

[0025] (3) Measure TSS concentration and VSS concentration after 7 days of anaerobic fermentation.

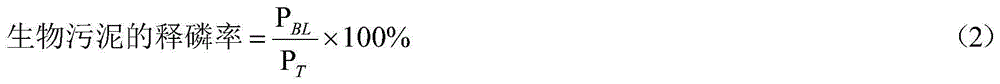

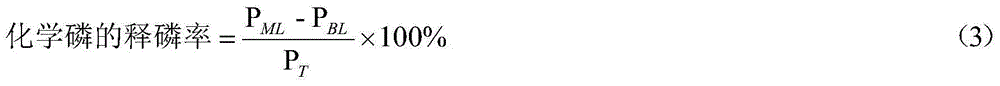

[0026] (4) The phosphorus release rates of mixed sludge, biological sludge and chemical sludge were calculated by formulas (1), (2) and (3) respectively under different conditions.

[0027]

[0028]

[0029]

[0030] Where: P T —Concentration of total phosphorus in muddy...

Embodiment 2

[0037] (1) Take 400mL of concentrated FePO-free 4 Biological sludge, containing FePO 4 The mixed sludge (total suspended solids concentration is 13.80g / L, volatile suspended solids concentration is 9.42g / L) is put into different reactors, and Na 2 S makes its concentration 0.13gNa 2 S / gTSS was anaerobically fermented in a closed reactor at 35°C for 8 days. At the same time without adding Na 2 The reactor of S served as a control.

[0038] (2) Sampling once every 24 hours, measuring the orthophosphate (PO 4 3- -P), dissolved organic carbon (STOC), volatile fatty acid (VFA) concentration

[0039] (3) Measure TSS concentration and VSS concentration after 8 days of anaerobic fermentation.

[0040] (4) Dosing 0.13gNa 2 S / gTSS with FePO 4 When the mixed sludge is jointly anaerobically fermented, about 77% of the phosphorus in the mixed sludge can be released after 8 days of anaerobic fermentation, and the phosphorus release rate of the biological sludge is 36%. 4 The phosp...

Embodiment 3

[0044] (1) Take 400mL of concentrated FePO-free 4 Biological sludge, containing FePO 4 The mixed sludge (total suspended solids concentration is 16.00g / L, volatile suspended solids concentration is 10.60g / L) is put into different reactors, and Na 2 S makes its concentration 0.20gNa 2 S / gTSS was anaerobically fermented in a closed reactor at 35°C for 5 days. At the same time without adding Na 2 The reactor of S served as a control.

[0045] (2) Sampling once every 24 hours, measuring the orthophosphate (PO 4 3- -P), dissolved organic carbon (STOC), volatile fatty acid (VFA) concentration

[0046] (3) Measure TSS concentration and VSS concentration after 5 days of anaerobic fermentation.

[0047] (4) Add 0.20gNa 2 S / gTSS with FePO 4 When the mixed sludge is jointly anaerobically fermented, about 83% of the phosphorus in the mixed sludge can be released after anaerobic fermentation for 5 days, and the phosphorus release rate of the biological sludge is 38%. 4 The phosph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com