Constructional energy-saving ceramic brick with passive humidity adjusting function and production method thereof

A ceramic brick and energy-saving technology, which is applied to building energy-saving passive humidity-regulating functional ceramic bricks and its production field, can solve the problems of small humidity capacity, slow humidity release speed, and high production cost, and achieve high cation exchange performance and humidity control High response rate, effect of increasing adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

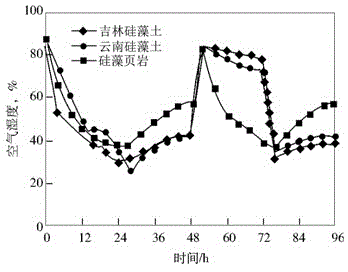

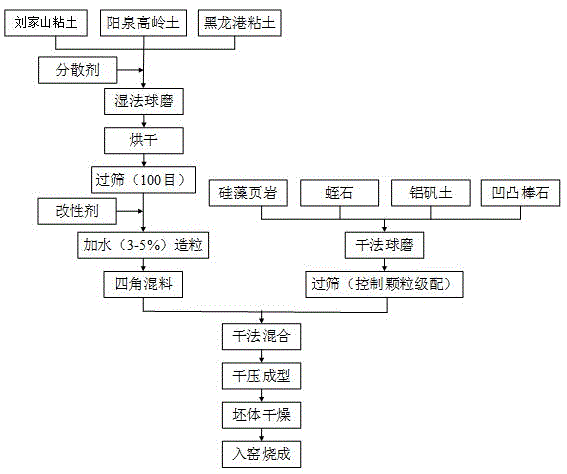

[0057] (1) Weigh and mix 12.6 parts of Liujiashan clay, 7.5 parts of Yangquan kaolin clay and 8.3 parts of Heilonggang clay, add 0.6 parts of dispersant for wet ball milling, and the fineness of the slurry after ball milling is 0.8% after sieving with a 250 mesh sieve, and dry After passing through a 100 mesh sieve, the dispersant is a commonly used dispersant for ceramics;

[0058] (2) Add 0.4 part of modifier to the sieved powder, add 3.0% of water to granulate, and mix evenly by quadrangular mixing method, wherein the modifier is dodecyltrimethylammonium chloride, ethanolamine, three Mixture of ethanolamine and silane coupling agent;

[0059] (3) Weigh and mix 34.6 parts of diatom shale, 10.9 parts of vermiculite, 15.8 parts of bauxite, and 9.3 parts of attapulgite, dry ball mill, and sieve to make the particle size below 80 mesh: 10%, 80 mesh-100 mesh: 25%, 100 mesh-200 mesh: 35%, 200 mesh or more: 30%;

[0060] (4) Dry mix the modified powder with diatom shale, vermicul...

Embodiment 2

[0063] (1) Weigh and mix 16.2 parts of Liujiashan clay, 12.0 parts of Yangquan kaolin clay, and 14.1 parts of Heilonggang clay, add 1.3 parts of dispersant to wet ball mill, and the fineness of the slurry after ball milling is 0.6% after 250 mesh sieve, and dry After passing through a 100 mesh sieve, the dispersant is a commonly used dispersant for ceramics;

[0064] (2) Add 0.9 parts of modifier to the sieved powder, add 4.0% of water to granulate, and mix evenly by four-corner mixing method. Among them, the modifier is octadecyltrimethylammonium chloride, triethanolamine, Titanate coupling agent mixing;

[0065] (3) Weigh and mix 20.9 parts of diatom shale, 13.6 parts of vermiculite, 8.7 parts of bauxite, and 12.3 parts of attapulgite, dry ball mill, and sieve to make the particle gradation below 80 mesh: 10%, 80 mesh-100 mesh: 25%, 100 mesh-200 mesh: 35%, 200 mesh or more: 30%;

[0066] (4) Dry mix the modified powder with diatom shale, vermiculite and bauxite mixture;

...

Embodiment 3

[0069](1) Weigh and mix 20.7 parts of Liujiashan clay, 16.4 parts of Yangquan kaolin clay, and 19.2 parts of Heilonggang clay, add 2.0 parts of dispersant for wet ball milling, and the fineness of the slurry after ball milling is 0.5% after 250 mesh sieve, and dry After passing through a 100 mesh sieve, the dispersant is a commonly used dispersant for ceramics;

[0070] (2) Add 1.5 parts of modifier to the sieved powder, add 5.0% of water to granulate, and mix evenly by using the four-corner mixing method. Among them, the modifier is octadecyltrimethylammonium chloride, dodecane Trimethyl ammonium chloride, dodecyl dimethyl benzyl ammonium chloride, ethanolamine mixed;

[0071] (3) Weigh and mix 14.7 parts of diatom shale, 8.1 parts of vermiculite, 9.8 parts of bauxite, and 7.7 parts of attapulgite, dry ball mill, and sieve to make the particle size below 80 mesh: 10%, 80 mesh-100 mesh: 25%, 100 mesh-200 mesh: 35%, 200 mesh or more: 30%;

[0072] (4) Dry mix the modified pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com