Silicon carbide fiber with Sibcn coating deposited on the surface and preparation method thereof

A technology of silicon carbide fiber and coating, which is applied in the direction of coating, metal material coating process, gaseous chemical plating, etc., can solve the problems of unsuitable industrialized preparation of SiBCN and complex process, etc., and achieve simple and convenient gas source control process. Good high temperature stability and improved oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

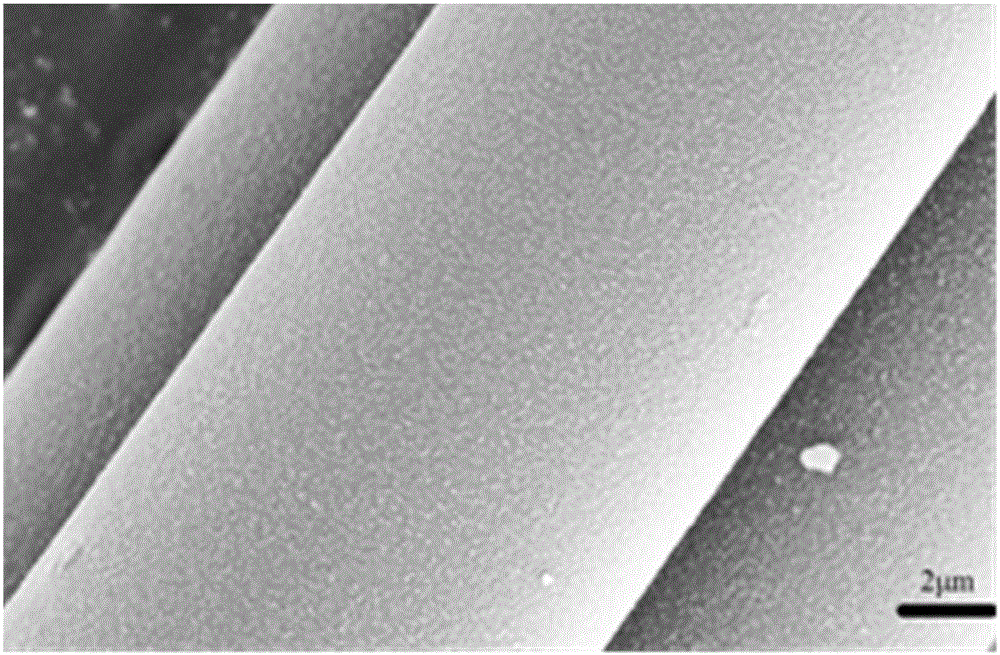

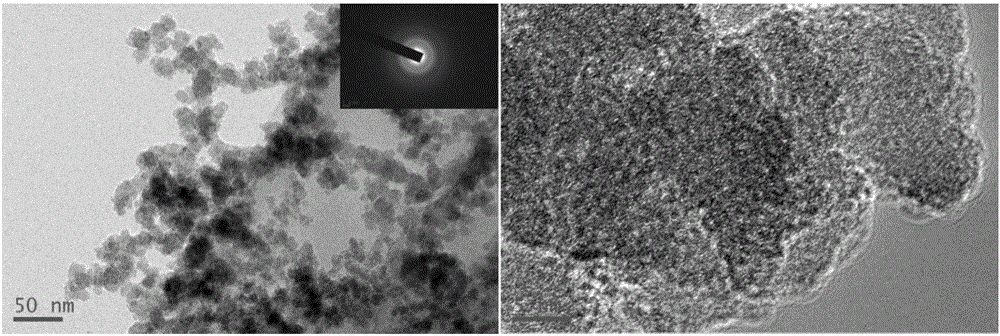

[0035] A silicon carbide fiber with a SiBCN coating deposited on the surface of the present invention, comprising a silicon carbide fiber substrate and a SiBCN coating deposited on the silicon carbide fiber substrate, the SiBCN coating and the silicon carbide fiber substrate are combined by mechanical interlocking and chemical bonding, and SiBCN The coating is prepared by chemical vapor deposition process using borazine and liquid polycarbosilane as raw materials. In this embodiment, the silicon carbide fiber matrix is a silicon carbide fiber monofilament, and the thickness of the SiBCN coating is 450 nm.

[0036] The preparation method of the above-mentioned SiBCN coated silicon carbide fiber on the surface of the present embodiment comprises the following steps:

[0037] (1) Place the silicon carbide fiber monofilament in the organic solvent acetone for ultrasonic cleaning, and the time of ultrasonic cleaning is controlled to 0.5h;

[0038] (2) Place the ultrasonically cl...

Embodiment 2

[0050] A silicon carbide fiber with a SiBCN coating deposited on the surface of the present invention, comprising a silicon carbide fiber substrate and a SiBCN coating deposited on the silicon carbide fiber substrate, the SiBCN coating and the silicon carbide fiber substrate are combined by mechanical interlocking and chemical bonding, and SiBCN The coating is prepared by chemical vapor deposition process using borazine and liquid polycarbosilane as raw materials. In this embodiment, the silicon carbide fiber matrix is silicon carbide fiber tow, and the thickness of the SiBCN coating is 350 nm.

[0051] The preparation method of the above-mentioned SiBCN coated silicon carbide fiber on the surface of the present embodiment comprises the following steps:

[0052] (1) Place the silicon carbide fiber bundles in the organic solvent acetone for ultrasonic cleaning, and the time for ultrasonic cleaning is controlled to 0.5h;

[0053] (2) Place the ultrasonically cleaned silicon c...

Embodiment 3

[0060] A silicon carbide fiber with a SiBCN coating deposited on the surface of the present invention, comprising a silicon carbide fiber substrate and a SiBCN coating deposited on the silicon carbide fiber substrate, the SiBCN coating and the silicon carbide fiber substrate are combined by mechanical interlocking and chemical bonding, and SiBCN The coating is prepared by chemical vapor deposition process using borazine and liquid polycarbosilane as raw materials. In this embodiment, the silicon carbide fiber matrix is a silicon carbide fiber braid, and the thickness of the SiBCN coating is 100 nm.

[0061] The preparation method of the above-mentioned SiBCN coated silicon carbide fiber on the surface of the present embodiment comprises the following steps:

[0062] (1) Place the silicon carbide fiber braid in the organic solvent acetone for ultrasonic cleaning, and the time of ultrasonic cleaning is controlled to 0.5h;

[0063] (2) Place the silicon carbide fiber braid aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com