Efficient composite emulsion modifier

A technology of composite emulsion and modifier, applied in building components, building insulation materials, buildings, etc., can solve the problems of network structure damage, easy to boil, poor storage stability, etc., to promote compatibility, reduce Gibbs free energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

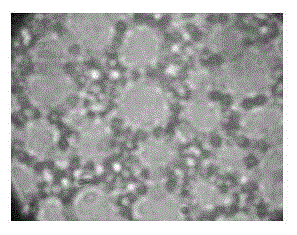

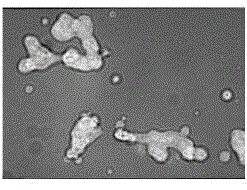

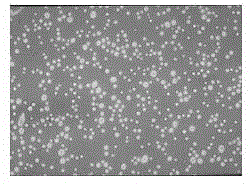

Image

Examples

Embodiment 1

[0032] A preparation method of high-efficiency composite emulsion modifier, comprising as follows:

[0033] (1) Preparation of styrene-butadiene-styrene thermoplastic elastomer aqueous latex;

[0034] (2) Add ethylene-vinyl acetate aqueous emulsion (FG-CP606W) / cationic anti-strong acid self-crosslinking modified acrylate emulsion (FG-H1811) to styrene-butadiene-styrene thermoplastic elastomer aqueous latex The blended emulsion is optimized and compounded; when the blending ratio of FG-CP606W / FG-H1811 is 80 / 20, the emulsion has the best performance; among them, styrene-butadiene-styrene thermoplastic elastomer water latex: Blended emulsion weight ratio = 1:3;

[0035] (3) In the room temperature asphalt composite emulsion, the weight percentage of styrene-butadiene-styrene thermoplastic elastomer water latex is 5%, the FG-CP606W / FG-H1811 blend emulsion (80 / 20) is 15%, and the asphalt 55% for water, 45% for water;

[0036] (4) Compound styrene-butadiene-styrene thermoplas...

Embodiment 2

[0040] A preparation method of high-efficiency composite emulsion modifier, comprising as follows:

[0041] (1) Preparation of styrene-butadiene-styrene thermoplastic elastomer aqueous latex;

[0042] (2) Add ethylene-vinyl acetate aqueous emulsion (FG-CP606W) / cationic anti-strong acid self-crosslinking modified acrylate emulsion (FG-H1811) to styrene-butadiene-styrene thermoplastic elastomer aqueous latex The blended emulsion is optimized and compounded; when the blending ratio of FG-CP606W / FG-H1811 is 80 / 20, the emulsion has the best performance; among them, styrene-butadiene-styrene thermoplastic elastomer water latex: Blended emulsion weight ratio=2:3

[0043] (3) In the room temperature asphalt composite emulsion, the weight percentage of styrene-butadiene-styrene thermoplastic elastomer water latex is 10%, the FG-CP606W / FG-H1811 blend emulsion (80 / 20) is 15%, and the asphalt 65% for water, 35% for water;

[0044] (4) Compound styrene-butadiene-styrene thermoplasti...

Embodiment 3

[0049] A preparation method of high-efficiency composite emulsion modifier, comprising as follows:

[0050] (1) Preparation of styrene-butadiene-styrene thermoplastic elastomer aqueous latex;

[0051] (2) Add ethylene-vinyl acetate aqueous emulsion (FG-CP606W) / cationic anti-strong acid self-crosslinking modified acrylate emulsion (FG-H1811) to styrene-butadiene-styrene thermoplastic elastomer aqueous latex The blended emulsion is optimized and compounded; when the blending ratio of FG-CP606W / FG-H1811 is 80 / 20, the emulsion has the best performance;

[0052] (3) In the room temperature asphalt composite emulsion, the weight percentage of styrene-butadiene-styrene thermoplastic elastomer water latex is 7%, the FG-CP606W / FG-H1811 blend emulsion (80 / 20) is 14%, the asphalt 58% for water, 29% for water;

[0053] (4) Compound styrene-butadiene-styrene thermoplastic elastomer water latex and optimized CP606W / H1811 according to the above mass ratio, and add lignoamine cationic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com